Embossed aluminum coils are premium metal products featuring raised decorative patterns on the surface. These coils combine functionality with aesthetic appeal, making them ideal for architectural and design applications where both durability and visual impact matter.

Key Advantages:

Enhanced slip resistance

Superior light diffusion

Excellent formability

Unique decorative effects

Classification of Embossed Aluminum Coils

Suppliers typically offer these main pattern types:

| Pattern Type | Depth (mm) | Best For | Finish Options |

|---|---|---|---|

| Diamond Embossed | 0.1-0.3 | Flooring, Wall Cladding | Mill, Anodized |

| Leather Grain | 0.2-0.5 | Elevator Interiors, Furniture | Painted, PVDF |

| Linear Grooved | 0.15-0.25 | Ceiling Panels, Partitions | Brushed, Coated |

| Custom Designs | 0.1-0.4 | Signature Architecture | All Finishes |

Thickness Specifications

Standard thickness options from suppliers:

| Thickness (mm) | Width Range (mm) | Typical Applications |

|---|---|---|

| 0.5-0.8 | 800-1600 | Interior Decorative Panels |

| 0.8-1.2 | 900-1500 | Building Facades |

| 1.2-2.0 | 1000-2000 | Heavy-Duty Flooring |

| 2.0-3.0 | 1200-2500 | Industrial Applications |

Alloy Options

Leading suppliers provide these common alloys:

| Alloy Series | Characteristics | Pattern Suitability |

|---|---|---|

| 3003 | Excellent formability | Complex deep patterns |

| 5005 | Good corrosion resistance | Standard embossing |

| 5052 | Higher strength | Heavy-duty applications |

| 6061 | Structural applications | Minimal pattern deformation |

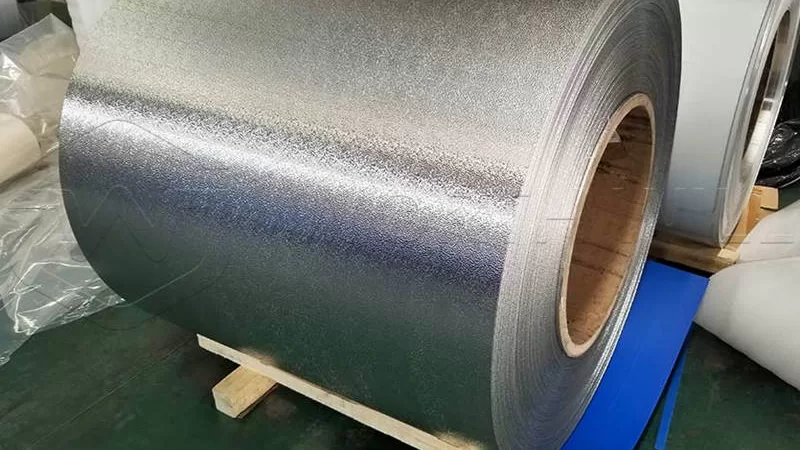

Packaging Standards

Quality suppliers ensure:

PVC film interleaving (pattern protection)

Waterproof wrapping (30-100m per coil)

Steel or wooden pallet bases

Edge protectors for all shipments

Custom packaging for special orders

Top 5 Industries Using Embossed Aluminum Coils

- Architecture & Construction

- Decorative wall panels

- Ceiling systems

- Column covers

- Transportation

- RV interiors

- Marine ceilings

- Train compartment linings

- Interior Design

- Feature walls

- Custom furniture surfaces

- Retail display backdrops

- Industrial Applications

- Non-slip walkways

- Equipment housings

- Machinery decoration

- Consumer Goods

- Appliance exteriors

- DIY project materials

- Artistic installations

Supplier Selection Criteria

When evaluating embossed aluminum coil suppliers, consider:

Pattern consistency across batches

Minimum order quantities (MOQs)

Custom pattern development capability

Finishing options availability

Lead time reliability

Quality Assurance Indicators

Reputable suppliers provide:

Mill test certificates

Sample approval process

Pattern depth verification

Surface quality guarantees

Consistent mechanical properties

Cost Factors

Pricing depends on:

Alloy grade

Pattern complexity

Order volume

Finish type

Packaging requirements

*Tip: Many suppliers offer price breaks at 5-ton quantities*

Global Supply Considerations

Major supplying regions:

Asia (China, India) – Cost competitive

Europe (Germany, Italy) – Premium quality

North America – Quick turnaround

Maintenance Requirements

- Embossed aluminum coils require:

- Regular cleaning with mild detergents

- Avoidance of abrasive tools

- Periodic inspection for deep patterns

- Touch-up painting when coated

Conclusion

Choosing the right embossed aluminum coil supplier requires balancing pattern quality, material specifications, and service reliability. Whether sourcing standard diamond patterns or custom-designed surfaces, prioritize suppliers with proven embossing expertise and quality control systems.

For architectural projects, consider suppliers offering:

Full technical support

Sample matching services

Installation guidance

After-sales support

Pro Tip: Request production samples before large orders to verify pattern definition and material quality.

The embossed aluminum coil market offers diverse solutions for both functional and decorative applications, with suppliers varying in capabilities from stock patterns to fully customized designs. By understanding your project’s specific requirements for thickness, alloy, and pattern type, you can identify the ideal supplier partnership.