3004 Aluminum Foil

3004 aluminum foil is a popular material used in a variety of industries due to its excellent properties, including high strength, good formability, and corrosion resistance.

It is a strong and durable option for packaging, insulation, and other applications.

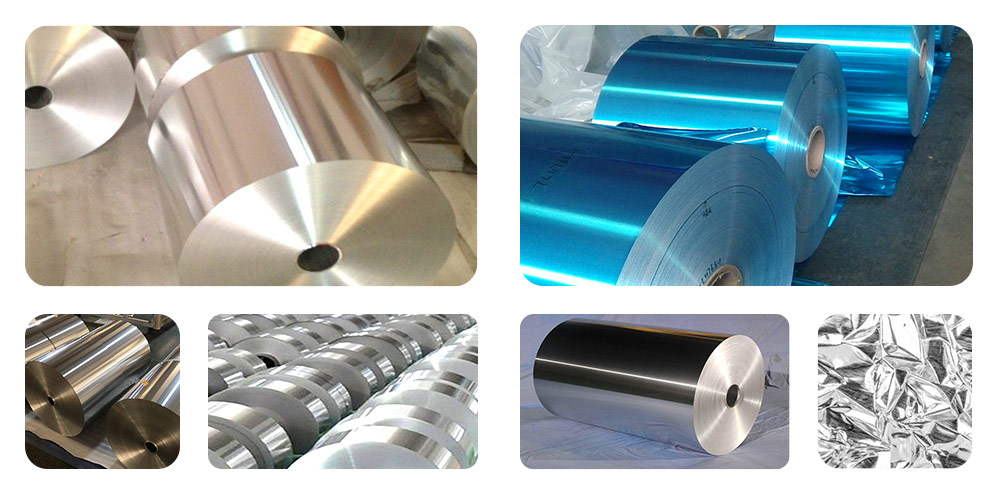

| Typical Alloy | 3004 Aluminum Foil |

| Temper | F, O, H14, H16, H18, H19, H22, H24, H26, H28 |

| Thickness(mm) | 0.018-0.2 |

| Widthness(mm) | 100-1500 |

| Length(mm) | C |

| Typical Products | Lunch box material, Food packaging foil, Container foil, etc |

What is 3004 aluminum used for?

One of the primary uses of 3004 aluminum foil is in the packaging industry. The foil can create flexible packaging.

For food and beverages, pharmaceuticals, and other consumer products.

Due to its strength and formability, it can be easily shaped and molded to create customized packaging solutions that protect and preserve the contents inside.

In The Construction

In addition to packaging, 3004 aluminum foil is also in the construction industry for insulation and roofing applications. The foil’s excellent thermal conductivity and reflective properties.

We can make an effective material for insulating buildings and improving energy efficiency.

It is as a roofing material in areas with extreme weather conditions, thanks to its corrosion resistance and durability.

In The Automotive Industry

Another industry that utilizes 3004 aluminum foil is the automotive industry. The foil is in the manufacturing of heat exchangers and other components. Due to its high strength and corrosion resistance.

Additionally, in the production of various types of industrial equipment and machinery.

Benefits

Overall, 3004 aluminum foil is a versatile material that offers a range of benefits across multiple industries.

Strength

formability

corrosion resistance

It is a popular choice for packaging, insulation, and other applications where durability and performance are key factors.

What is the difference between 3003 and 3004 aluminum?

3003 and 3004 aluminum are both aluminum alloys with similar characteristics, but there are some key differences between them.

3003 Aluminum

Aluminum 3003 is an alloy that contains manganese as its primary alloying element. It is a non-heat-treatable alloy in general-purpose applications. Such as sheet metal work, cooking utensils.

It has good corrosion resistance, excellent workability.

It is easy to weld.

3004 Aluminum

On the other hand, 3004 aluminum is an alloy that contains both manganese and magnesium as its primary alloying elements.

It is also a non-heat-treatable alloy that is commonly in applications that require higher strength and better resistance to corrosion than 3003 aluminum. 3004 aluminum is often for making beverage cans, as well as for sheet metal work, and it is also easy to weld.

In summary, while both 3003 and 3004 aluminum are non-heat-treatable alloys. They have application in sheet metal work. 3004 aluminum has better strength and corrosion resistance due to the addition of magnesium to its composition.