Introduction to .016 Aluminum Jacketing

In industrial and commercial settings, maintaining the integrity and efficiency of insulation systems on pipes, ducts, tanks, and vessels is crucial. This is where 016 aluminum jacketing plays a vital role.

The “016” refers to its thickness in inches (approximately 0.4 mm), a widely adopted standard that balances durability, flexibility, and cost-effectiveness. This robust material acts as a protective shield, guarding the underlying thermal and acoustic insulation from mechanical damage, harsh weather, UV radiation, and corrosive elements.

What Does “016” Mean for Aluminum Jacketing?

The “.016” in .016 aluminum jacketing signifies its thickness in inches. This translates to roughly 0.406 millimeters. This specific gauge has become a preferred standard across various industries due to its optimal balance of characteristics:

- Durability: Provides substantial protection against physical impact and wear without being overly heavy or difficult to handle.

- Flexibility: While strong, it remains pliable enough for easy cutting, forming, and wrapping around diverse insulated surfaces.

- Cost-Effectiveness: Offers excellent protective qualities at a more economical price point compared to thicker gauges, making it a budget-friendly option for large projects.

This precise thickness ensures .016 aluminum jacketing is a versatile and reliable choice for many applications.

Standard Specification for Aluminum Jacketing for Insulation

The performance and quality of aluminum jacketing for insulation are governed by industry standards to ensure consistency and reliability. In North America, ASTM B209 is a key specification covering aluminum sheet and plate. For insulation jacketing, industry practices often refer to general requirements for physical and chemical properties. Key aspects typically covered in specifications include:

| Specification Aspect | Description |

|---|---|

| Alloy Type | Chemical composition, e.g., 3003, 3105, 1100, 5005. |

| Temper | Hardness and strength of the aluminum, e.g., H14, H16. |

| Thickness | Nominal thickness, such as .016 inches (0.406 mm). |

| Surface Finish | Texture, e.g., mill finish, stucco embossed, smooth. |

| Moisture Barrier | If included, type and properties of the barrier, e.g., Polyfilm Moisture Barrier. |

Adhering to these specifications ensures that the aluminum jacketing will perform reliably in its intended environment.

Common Alloys for 016 Aluminum Jacketing

The chosen aluminum alloy significantly impacts the performance of .016 aluminum jacketing. Here are the most commonly used alloys:

| Alloy | Key Characteristics | Typical Use for .016 Jacketing |

|---|---|---|

| 1100 | Commercially pure aluminum, excellent corrosion resistance, high ductility, lower strength. | General-purpose jacketing where high strength isn’t critical, easy to form. |

| 3003 | Aluminum-manganese alloy, good strength-to-weight ratio, excellent corrosion resistance, very good workability. | Most common choice for .016 aluminum jacketing, versatile for many industrial settings. |

| 3105 | Similar to 3003, but with slightly higher strength and good formability. | Used when slightly more rigidity or strength is required than 3003. |

| 5005 | Aluminum-magnesium alloy, excellent corrosion resistance (especially marine environments), good weldability, moderate strength. | For coastal, marine, or highly corrosive industrial environments. |

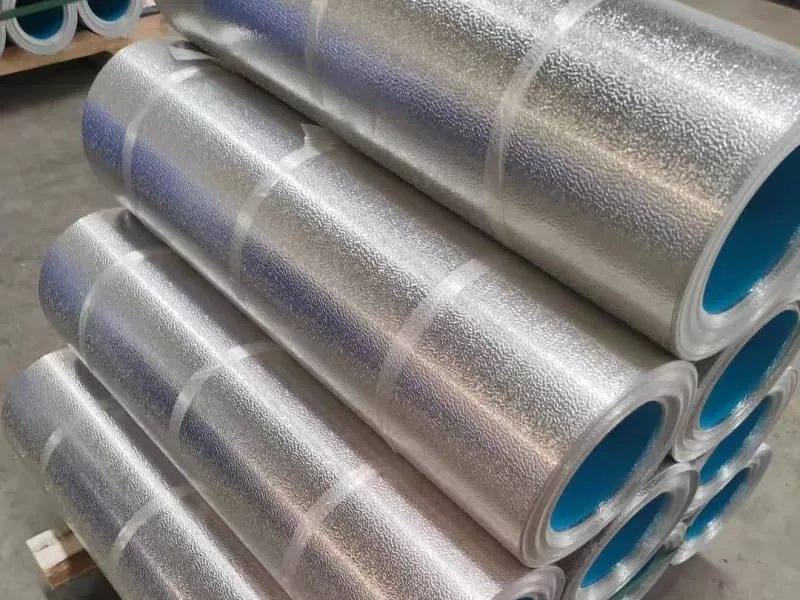

016 Stucco Embossed Aluminum Jacketing

One of the most prevalent forms of this product is .016 stucco embossed aluminum jacketing. The “stucco embossed” finish features a textured pattern pressed into the aluminum surface. This finish provides several practical advantages:

- Reduced Glare: The textured surface diffuses light, minimizing reflections, which is ideal for outdoor installations and reduces eye strain.

- Increased Rigidity: The embossing process slightly stiffens the material, making it less prone to buckling and easier to handle during installation.

- Hides Minor Imperfections: The pattern effectively masks small dents, scratches, or oil canning, maintaining a clean and professional appearance over time.

- Enhanced Aesthetics: Provides a consistent and uniform look to insulated systems.

A common size example is .016 x 36″ x 100′ stucco embossed aluminum, which specifies the thickness, a common width (36 inches), and a standard roll length (100 feet).

Aluminum Roll Jacketing

Aluminum roll jacketing is the most common form in which .016 aluminum jacketing is supplied. It comes wound onto sturdy cores, making it easy to transport, unroll, and cut to specific lengths on-site. The continuous roll format minimizes waste and provides flexibility for covering various pipe and duct diameters.

Benefits of aluminum roll jacketing:

- Versatility: Adaptable for both large and small diameter pipes, as well as rectangular ducts.

- Efficiency: Allows installers to cut exact lengths, reducing material scrap and costs.

- Ease of Handling: Lighter than pre-cut sheets, facilitating transport and installation.

- Seamless Application: Can cover long runs with fewer seams, enhancing overall protection and appearance.

Aluminum Roll Jacketing with Polyfilm Moisture Barrier

For applications where moisture protection is paramount, Aluminum Roll Jacketing with Polyfilm Moisture Barrier is indispensable. A moisture barrier is a protective layer laminated to the interior surface of the aluminum jacketing. It serves two critical functions:

- Prevents Galvanic Corrosion: Direct contact between aluminum and certain types of insulation (especially those containing chlorides or other corrosive agents), in the presence of moisture, can lead to galvanic corrosion. The barrier acts as an electrical insulator, preventing this destructive reaction.

- Blocks Moisture Ingress: It forms an additional line of defense against water vapor, rain, and condensation, ensuring the insulation remains dry and effective.

Common polyfilm barriers include Polykraft (polyethylene laminated to kraft paper) or Polysurlyn (DuPont™ Surlyn® polymer film). For .016 aluminum jacketing, selecting the appropriate moisture barrier is crucial for long-term performance, particularly in outdoor or high-humidity environments.

Special Finish Aluminum Pipe Jacketing

While stucco embossed is widely popular, special finish aluminum pipe jacketing offers alternatives for specific aesthetic or functional requirements.

| Finish Type | Description | Typical Application / Benefit |

|---|---|---|

| Smooth Finish | Clean, reflective appearance without texture. | Desired for a high-gloss look or easier cleaning. |

| Colored/Painted | Factory-applied paint in various colors. | Matches branding, architectural designs, or identifies pipe contents. |

| Clear Anodized | Electrochemical process creating a hard, clear, corrosion-resistant surface. | Enhanced durability and aesthetics, often for architectural applications. |

| Mill Finish | The raw, un-embossed finish directly from the rolling mill. | Typically used when the jacketing will be covered or painted on-site. |

These special finishes allow for greater customization beyond the standard .016 stucco embossed aluminum jacketing.

Key Benefits of 016 Aluminum Jacketing

Choosing .016 aluminum jacketing offers numerous advantages for insulation systems:

- Superior Protection: Shields insulation from physical impact, UV degradation, and environmental exposure.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, making it highly resistant to rust and various chemicals.

- Lightweight: Easy to transport and install, contributing to reduced labor costs.

- Durable: Withstands harsh conditions, extending the lifespan and performance of the insulation system.

- Energy Efficiency: By protecting insulation, it helps maintain thermal performance, leading to significant energy savings.

- Aesthetic Appeal: Provides a clean, professional finish, especially with stucco embossed or other special finish aluminum pipe jacketing.

The Applications of Aluminum Jacket in Pipe Systems

The robust and versatile nature of .016 aluminum jacketing makes it suitable for a wide range of applications, often serving as the primary aluminum jacket for pipe insulation.

- HVAC Systems: Protecting insulated air ducts, chilled water lines, and heating pipes in commercial buildings.

- Oil & Gas Refineries: Safeguarding process piping, storage tanks, and vessels from harsh environments and potential damage.

- Chemical Plants: Protecting insulated pipelines from corrosive atmospheres and chemical spills.

- Power Generation: Covering steam lines, turbines, and associated pipework, crucial for thermal efficiency.

- Industrial Facilities: For any exposed insulated piping or equipment requiring mechanical and weather protection.

- Food & Beverage Industry: Maintaining sanitary conditions and thermal integrity of process lines.

- Marine & Offshore: Protecting piping on ships and offshore platforms from saltwater corrosion and extreme weather.

Factory Production and Quality Assurance

A reputable factory producing 016 aluminum jacketing adheres to stringent quality control measures to ensure consistent, high-quality products. From sourcing prime aluminum coils to precise rolling, embossing, and barrier lamination, every step is critical. Factories ensure:

- Dimensional Accuracy: Consistent thickness (e.g., .016 inches), width (e.g., 36 inches), and length (e.g., 100 feet).

- Material Integrity: The correct alloy and temper are used for optimal performance.

- Finish Quality: Uniform stucco embossed pattern or flawless special finish.

- Barrier Adhesion: Secure lamination of the Polyfilm Moisture Barrier when specified.

- Compliance: Meeting relevant industry standards (like ASTM) and customer specifications.

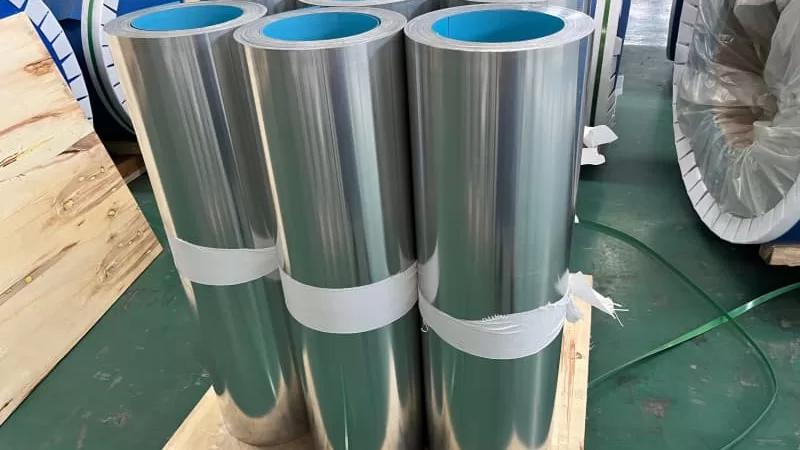

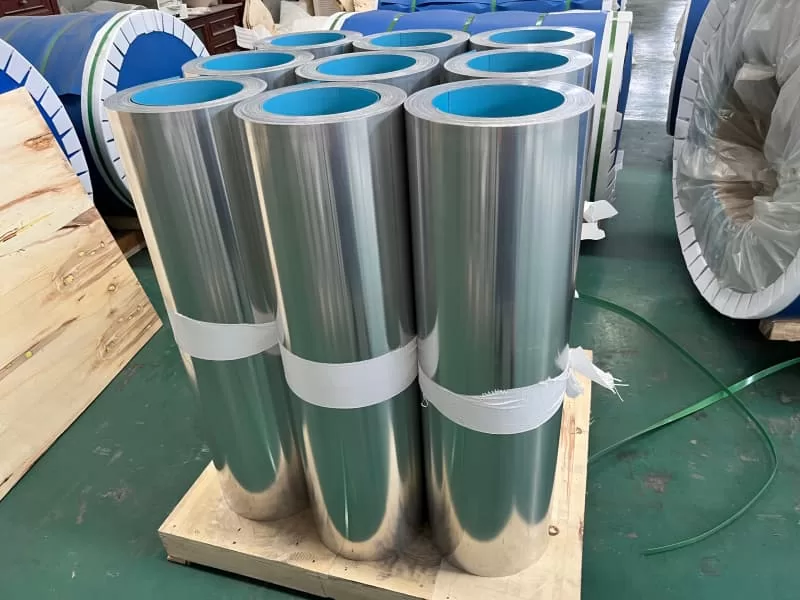

Packaging and Delivery

Proper packaging is essential to ensure that 016 aluminum jacketing arrives at the job site in perfect condition.

- Roll Jacketing: Typically wound on sturdy cardboard or plastic cores, individually wrapped in moisture-resistant paper or film, and then often palletized or crated for bulk protection during transit.

- Edge Protection: Roll edges are protected with guards to prevent damage during handling and shipping.

- Labeling: Products are clearly labeled with specifications such as thickness, alloy, finish, and barrier type for easy identification.

FAQ

Q1: What is the main benefit of using .016 aluminum jacketing over thinner gauges?

A: .016 aluminum jacketing offers significantly enhanced durability and mechanical protection compared to thinner gauges. It strikes an excellent balance, providing robust defense against physical damage and environmental factors for industrial insulation without being overly heavy or difficult to handle.

Q2: Why choose stucco embossed over a smooth finish for .016 aluminum jacketing?

A: The stucco embossed finish for .016 aluminum jacketing offers several advantages: it reduces glare, increases the material’s rigidity, and effectively hides minor imperfections, scratches, and oil canning. This results in a more uniform and visually appealing finish suitable for many industrial and outdoor applications.

Q3: Is a Polyfilm Moisture Barrier always necessary for aluminum roll jacketing?

A: A Polyfilm Moisture Barrier is highly recommended and often essential for aluminum roll jacketing, especially in outdoor, humid, or corrosive environments. It prevents galvanic corrosion between the aluminum and insulation materials and protects the insulation from moisture ingress, which can severely degrade its thermal performance.

Q4: Can .016 aluminum jacketing be used for both pipes and ducts?

A: Yes, .016 aluminum jacketing is highly versatile and is commonly used as aluminum jacket for pipe insulation and for both rectangular and round ductwork. Its flexibility and ease of fabrication make it suitable for a wide range of insulated geometries.

Q5: What alloy is typically used for 016 aluminum jacketing?

A: The 3003 aluminum alloy is the most common choice for016 aluminum jacketing due to its excellent balance of corrosion resistance, moderate strength, and good workability. Other alloys like 1100, 3105, or 5005 may be used for specific applications requiring different characteristics.