Custom perforated aluminum sheets are versatile materials featuring precisely punched holes in various patterns, sizes, and layouts. These sheets are widely used in architecture, industrial design, and decorative applications due to their functionality, aesthetic appeal, and durability. The customization options allow for unique designs tailored to specific project requirements.

What Are Custom Perforated Aluminum Sheets?

Perforated aluminum refers to aluminum sheets that have been punched with a variety of holes. These holes can be in different shapes and sizes, creating a unique pattern. You decide the hole pattern, hole size, material thickness, and even the finish. This allows for a product that perfectly fits your specific needs.

Custom perforated aluminum sheets are lightweight yet durable. They are also highly resistant to rust and corrosion, making them suitable for both indoor and outdoor use.

Why Choose Custom Perforated Aluminum?

Choosing custom perforated aluminum brings many advantages over standard materials. It offers a unique blend of aesthetic appeal and functional benefits.

| Key Benefit | Description |

|---|---|

| Design Flexibility | You can create almost any look you want. From simple patterns to complex designs, custom perforated aluminum allows for truly unique architectural and design elements. |

| Lightweight | Aluminum is naturally light. This makes perforated aluminum panels easy to handle and install, reducing overall structural load, especially important for large facades or ceiling applications. |

| Durability | Aluminum is strong and lasts a long time. It resists wear and tear, making it a good investment. |

| Corrosion Resistant | Unlike steel, aluminum does not rust. This makes it ideal for outdoor use and in humid environments, ensuring your perforated metal remains pristine. |

| Ventilation | The holes allow air to pass through freely. This is great for ventilation systems, equipment enclosures, or anywhere airflow is needed. |

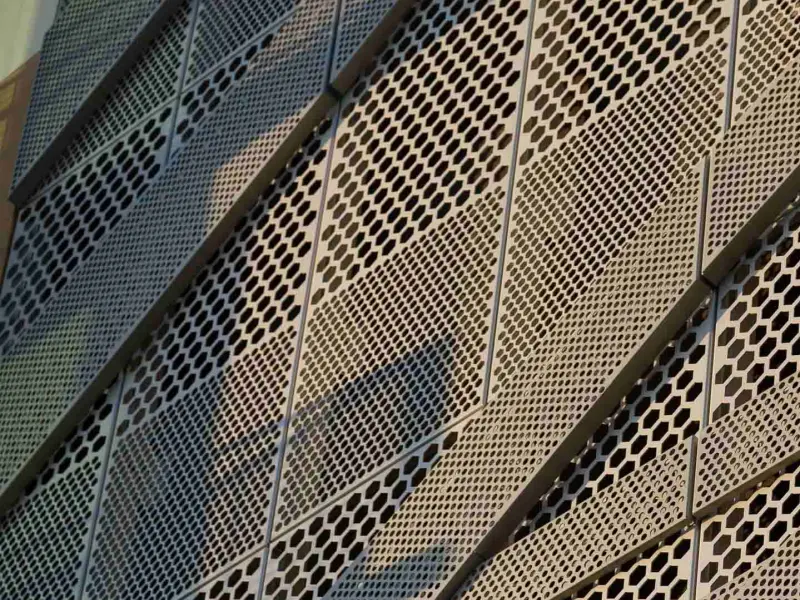

| Light Control | Perforated aluminum can diffuse light, reducing glare while still allowing natural light to enter. It’s excellent for sunshades or light diffusers. |

| Sound Absorption | The perforations can help to reduce noise. This makes them useful for acoustic panels in offices, studios, or public spaces, improving sound quality. |

| Aesthetic Appeal | With various patterns and finishes, custom perforated aluminum adds a modern and stylish look to any space. It can be a strong visual element in both interior and exterior designs. |

| Sustainability | Aluminum is 100% recyclable. Choosing perforated aluminum sheets means you are making an environmentally friendly choice. |

Types and Specifications of Custom Perforated Aluminum

The true power of custom perforated aluminum sheets lies in the wide range of options available. You can specify every detail to meet your project’s exact requirements.

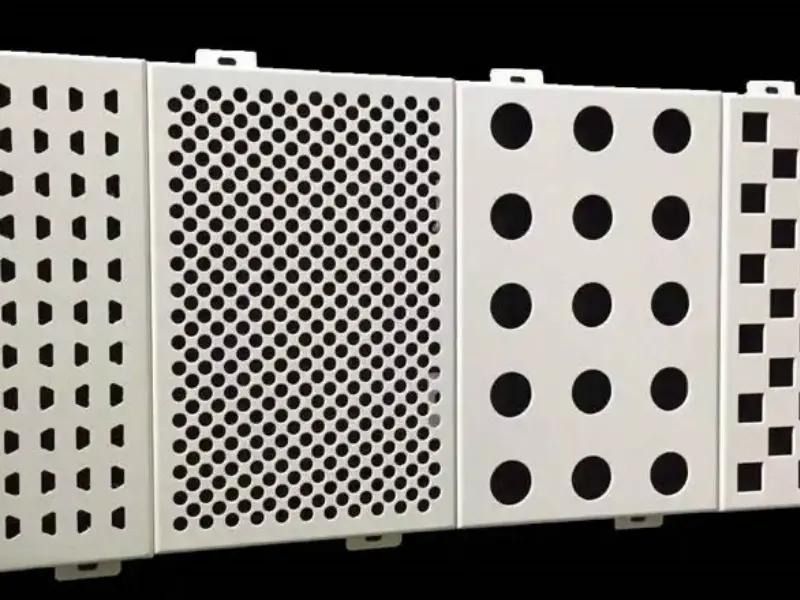

Common Hole Patterns

Different hole patterns create different visual and functional effects.

| Hole Pattern Type | Description |

|---|---|

| Round Holes | The most common and versatile. Offers excellent ventilation and a clean, modern look. |

| Square Holes | Provides a more industrial or geometric appearance. Good for grilles and guards where a specific pattern is desired. |

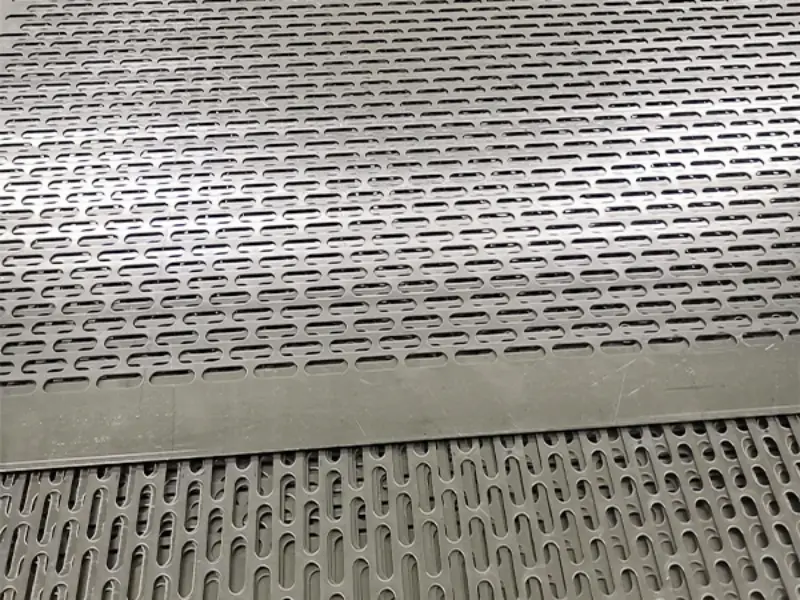

| Slotted Holes | Elongated holes, often used for drainage, screening, or when a directional visual effect is needed. |

| Decorative Holes | Includes various unique shapes like hexagonal, star, or cloverleaf. Used mainly for artistic and architectural purposes to create distinctive decorative panels. |

Typical Specifications

When ordering custom perforated aluminum, you will need to provide specific details about the sheet and its perforations.

| Specification | Details to Consider |

|---|---|

| Material Type | Primarily Aluminum Alloys (e.g., 1100, 3003, 5052). Different alloys offer varying levels of strength and workability. |

| Sheet Thickness | Typically ranges from 0.020 inches (0.5 mm) to 0.250 inches (6.35 mm). Thicker sheets offer more rigidity; thinner sheets are lighter. |

| Hole Size | From very small (e.030 inches / 0.75 mm) to large (1 inch / 25 mm or more). The hole size directly impacts airflow, light transmission, and visual transparency. |

| Hole Pitch | The distance from the center of one hole to the center of the next. Determines the open area percentage and the overall pattern density. For example, a 1/4″ hole on 1/2″ centers. |

| Open Area | The percentage of the sheet that is open space. Ranges from 20% to over 60%. Higher open area means more airflow and light. |

| Sheet Size | Standard sizes (e.g., 4ft x 8ft, 4ft x 10ft) or custom fabrication to specific dimensions to minimize waste and ensure a perfect fit. |

| Finishes | Options include mill finish (natural aluminum), anodizing (for color and corrosion protection), powder coating (for durability and a wide range of colors), or polishing. |

Applications of Perforated Aluminum Sheets

The versatility of perforated aluminum makes it suitable for a vast array of applications across different industries.

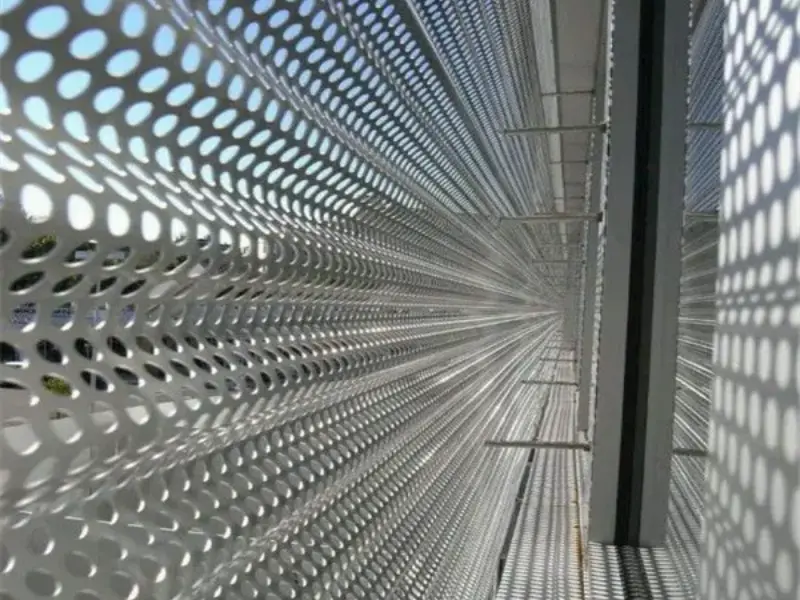

- Architectural Facades and Cladding: Used for building exteriors, creating unique visual effects, sun screening, and ventilation.

- Sunshades and Louvers: Controls sunlight and provides shade, reducing energy costs.

- Balcony Panels and Railings: Offers privacy, safety, and a modern aesthetic.

- Privacy Screens and Dividers: Creates separation in open spaces while maintaining an airy feel.

- Ceiling Panels and Acoustic Systems: Improves sound quality and adds a decorative element.

- Interior Design Elements: Used for decorative walls, light fixtures, and furniture components.

- Ventilation Grilles: Allows airflow in HVAC systems and machinery enclosures.

- Filtration Screens: For air, water, and industrial applications.

- Security Screens: Provides protection while maintaining visibility and airflow.

- Retail Displays and Shelving: Lightweight and stylish options for product presentation.

- Automotive and Transportation: Grilles, filters, and decorative components.

- Signage and Branding: Unique background or letters for signs.

Advantages of Custom Fabrication

This avoids the need for on-site modifications, saving time and money. It also ensures that the final product meets your exact design vision and functional requirements. With custom metal panels, you’re not just buying a material; you’re investing in a tailored solution.

How to Order Your Custom Perforated Aluminum Sheet

Ordering custom perforated aluminum is a straightforward process:

- Define Your Needs: Clearly identify the purpose of the sheet (e.g., facade, privacy screen, ventilation).

- Specify Design: Choose your desired hole pattern, hole size, pitch, material thickness, and overall dimensions. Consider any special finishes or bending requirements.

- Request a Quote: Contact a specialized supplier with your specifications. They will provide pricing and lead times.

- Review and Approve: Check the details and drawings before production begins.

- Production and Delivery: Your custom perforated aluminum sheet will be manufactured to your exact specifications and delivered to your site.

Frequently Asked Questions (FAQ)

| Question | Answer |

|---|---|

| Can perforated aluminum be painted? | Yes, perforated aluminum can be powder coated in almost any color. This adds an extra layer of protection and allows for complete design integration. |

| Is custom perforated aluminum expensive? | While initial costs might be slightly higher than standard materials, its durability, low maintenance, and long lifespan often result in lower overall costs. The ability to achieve specific designs also adds significant value. |

| How do I clean perforated aluminum? | Cleaning is simple. For most applications, a mild soap and water solution with a soft cloth or brush is sufficient. Avoid harsh chemicals that could damage the finish. |

| What is “open area” and why is it important? | The open area is the percentage of the sheet that is made up of holes. It’s crucial for determining how much light, air, or sound will pass through the perforated metal. A higher open area means more transparency and airflow. |

| Can custom perforated aluminum be bent? | Yes, aluminum is quite workable. Custom perforated aluminum sheets can be bent, rolled, and formed into various shapes, adding another layer of design flexibility to your project. |

| What’s the difference between perforated and expanded metal? | Perforated metal is made by punching holes into a solid sheet. Expanded metal is made by slitting and stretching a sheet, creating diamond-shaped openings with no waste. Both are metal panels but have different appearances and strengths. |