Are you looking for reliable anodised aluminium sheet suppliers? We provide high-quality anodized aluminum sheets in a wide range of sizes, finishes, and colors—ideal for architectural, industrial, and decorative use. Our anodized sheets offer excellent corrosion resistance, surface durability, and a premium metallic finish.

Specifications of Anodised Aluminium Sheets

| Property | Details |

|---|---|

| Alloy Grades | 1050, 1060, 1100, 3003, 5005, 5052 |

| Temper | H14, H24, H32, O |

| Thickness | 0.3 mm – 5.0 mm |

| Width | Up to 1500 mm |

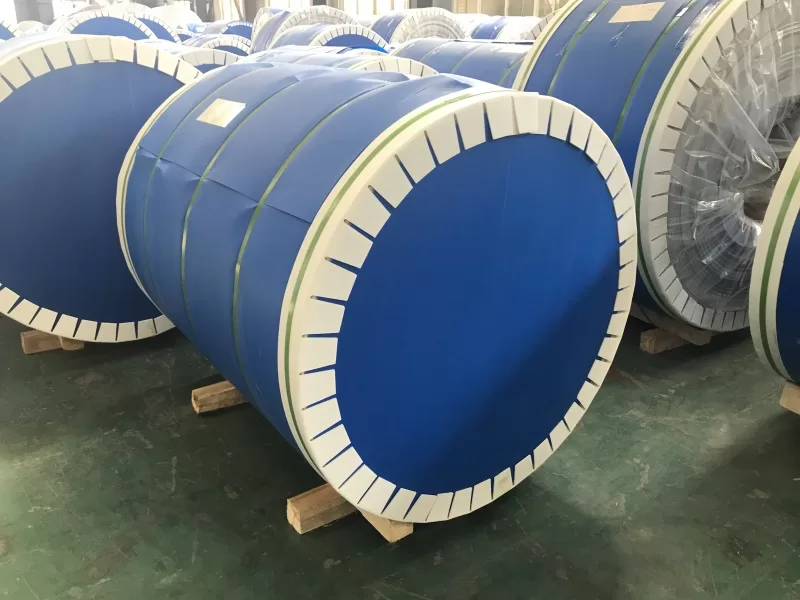

| Length | Up to 6000 mm or coil format |

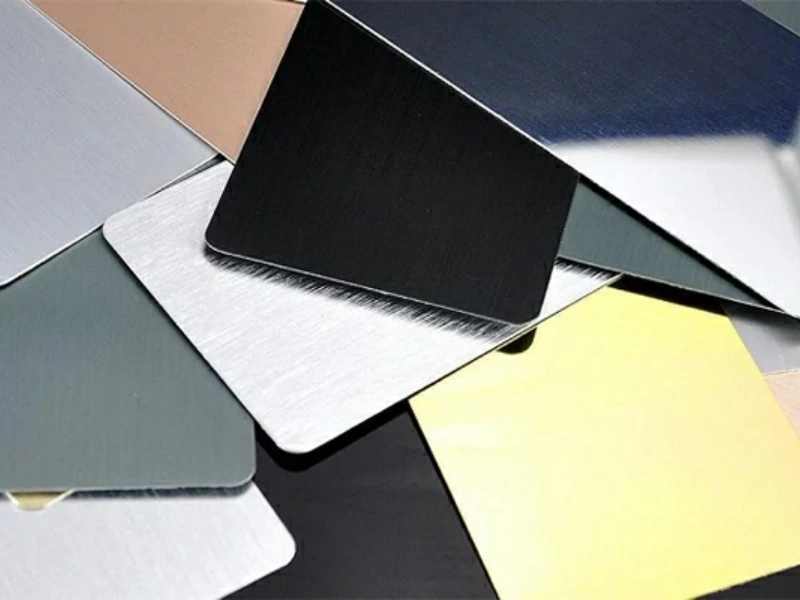

| Finish Types | Bright, brushed, satin, matte, mirror |

| Colors Available | Silver, black, bronze, gold, blue, red |

| Anodising Thickness | 5μm – 25μm (customizable) |

Custom cutting, drilling, bending, and protective film coating are available upon request.

Types of Anodised Aluminium Sheets We Offer

Clear Anodised Sheets

- Natural silver look

- Common in architecture and signage

Colored Anodised Sheets

- Available in black, gold, bronze, red, and blue

- Used in interior design, panels, nameplates

Brushed Anodised Aluminium

- Textured surface with hairline finish

- Ideal for furniture, appliances, wall cladding

Mirror Anodised Sheets

- High-reflective surface

- Suitable for decoration and display units

Advantages of Anodised Aluminium Sheets

- ✅ Corrosion-resistant – Ideal for outdoor or humid environments

- ✅ Hard surface – Scratch- and wear-resistant

- ✅ Non-peeling surface – The anodised layer won’t flake

- ✅ Color stability – UV-resistant dyed finishes

- ✅ Aesthetic appeal – Premium look for modern design

- ✅ Lightweight and easy to process – Cut, drill, or bend as needed

With these properties, anodised aluminum is one of the most versatile sheet metals available.

Applications of Anodised Aluminium Sheets

Anodised aluminum sheets are used across many industries:

🏗️ Architecture and Construction

- Curtain walls

- Wall cladding panels

- Roof facades

- Window frames

🛋️ Interior Decoration

- Cabinet panels

- Room dividers

- Elevator panels

- Decorative trims

🧰 Industrial Use

- Machine covers

- Control panels

- Electrical enclosures

📛 Signage and Labels

- Nameplates

- Direction signs

- Control panel overlays

🎁 Consumer Products

- Electronics casings

- Kitchen appliances

- Custom packaging

Our customers include builders, fabricators, designers, and engineers who trust us as experienced anodised aluminium sheet suppliers.

What Is Anodised Aluminium Sheet?

Anodised aluminium sheets are aluminum plates that have gone through an electrochemical process to form a protective oxide layer on the surface. This layer is hard, durable, and corrosion-resistant. It also improves the appearance of the metal, giving it a uniform, glossy, or matte finish.

Anodising not only enhances durability but also allows color dyeing, making the sheets attractive for both functional and decorative applications.

Why Choose Us as Your Aluminium Sheet Supplier

We stand out as trusted anodised aluminium sheet suppliers for several reasons:

- 🏭 In-house anodising line – strict quality control

- 🧪 Certified alloys and surface finish standards

- 🎨 Wide range of colors and finishes

- 📏 Custom cutting and fabrication available

- 📦 Secure packaging and fast delivery

- 🌍 Global shipping with flexible trade terms (FOB, CIF, DDP)

- 📞 Fast response and professional support

We supply aluminum sheets for projects of all sizes—from one-off custom pieces to full container orders.

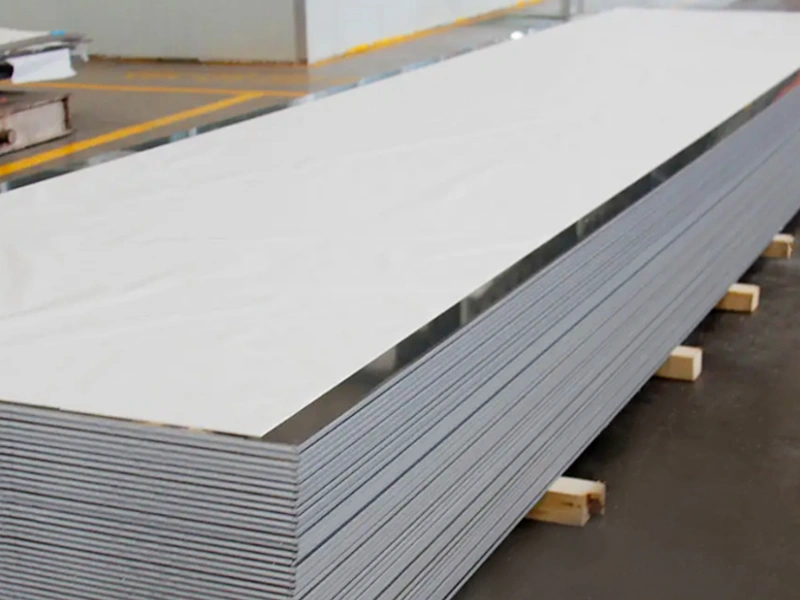

Packaging and Delivery

We ensure your anodised aluminium sheets arrive safely:

- 📦 PE film or paper between each sheet

- 🧃 Sheets stacked on wooden or steel pallets

- 🪵 Export packaging with shrink wrap or corner protectors

- 🏷️ Each pallet labeled with alloy, size, finish, and quantity

- 🚛 Fast delivery: 7–15 working days for regular orders

- ✈️ Global delivery via sea freight or air express available

Let us know your packaging and shipping requirements—we support OEM and mixed product loads.

Frequently Asked Questions (FAQ)

❓ What is the difference between anodised and painted aluminum?

Anodising is a permanent oxide finish, while paint is a surface coating. Anodised aluminum is more durable, won’t peel, and provides better scratch resistance.

❓ Can you supply colored anodised aluminum sheets?

Yes, we offer black, gold, bronze, blue, red, and custom color options using electrolytic dyeing.

❓ Are anodised sheets suitable for outdoor use?

Absolutely. Anodised finishes are UV-stable and corrosion-resistant, ideal for outdoor environments.

❓ Can you cut sheets to custom sizes?

Yes, we offer cut-to-size services as well as drilling and edge finishing.

❓ What is the minimum order quantity?

We can supply small trial orders or bulk container loads, depending on your needs.

Understanding Manufacturer Capabilities

Production Methods

Leading manufacturers utilize:

- Continuous coil anodising for high-volume orders

- Batch processing for custom colors/thicknesses

- Computer-controlled dipping for consistent quality

- Automated quality inspection systems

Key Manufacturing Equipment

Anodising tanks (sulfuric acid or hardcoat)

Precision leveling machines

Color dye baths with pH monitoring

Sealing ovens with temperature control

Laser measuring for thickness verification

Manufacturer Certifications Matter

Essential Certifications

- ISO 9001: Quality management systems

- ISO 14001: Environmental compliance

- Qualanod: European anodising quality standard

- AAMA 611: North American architectural standard

- ASTM B137: Standard specification for anodised products

Testing Capabilities

Reputable manufacturers conduct:

- Salt spray testing (ASTM B117)

- Adhesion testing (ASTM D3359)

- Colorfastness testing (ASTM D2244)

- Coating thickness measurements

Manufacturing Process Insights

Step-by-Step Production

- Material Preparation:

- Chemical cleaning

- Etching for surface uniformity

- Anodising:

- Electrolytic oxidation

- Current density control (12-18 ASF)

- Coloring (if applicable):

- Electrolytic coloring (bronze/gray)

- Organic dye dipping (vibrant colors)

- Sealing:

- Hot water sealing (96-100°C)

- Nickel acetate sealing (enhanced corrosion)

Quality Control Points

- Pre-treatment surface inspection

- Anodic layer thickness monitoring

- Color consistency checks

- Final hardness testing (for hardcoat)

Manufacturer Selection Criteria

Technical Capabilities

- Maximum sheet width/length capacity

- Available alloy selection

- Color options and custom matching

- Minimum/maximum order quantities

Service Offerings

- Just-in-time inventory programs

- Value-added services (cutting, forming)

- Technical support and engineering assistance

- Sample program availability

Global Manufacturing Landscape

Regional Specializations

- Asia: Cost-effective high volume production

- Europe: Premium architectural quality

- North America: Quick-turn custom orders

- Middle East: Specialty high-temperature alloys

Emerging Trends

- Environmentally friendly anodising processes

- Digital color matching technology

- Automated material handling systems

- Energy-efficient anodising plants

Working with Manufacturers Effectively

Ordering Tips

- Provide complete specifications upfront

- Request material certifications

- Clarify packaging requirements

- Discuss lead times realistically

Red Flags to Watch

- Inconsistent sample quality

- Lack of process documentation

- Unwillingness to provide factory tours

- No references from similar clients

Future of Anodised Aluminium Manufacturing

Innovation Areas

- Self-healing anodic coatings

- Antimicrobial surface treatments

- Improved color retention technology

- Thinner yet more durable layers

Sustainability Focus

- Closed-loop water systems

- Acid recovery processes

- Renewable energy powered plants

- Reduced chemical usage formulations

Get a Quote from Top Anodised Aluminium Sheet Suppliers

If you’re looking for high-quality anodised aluminium sheets at factory prices, you’re in the right place. We support global clients with customized orders, technical support, and fast service.

📧 Email: jane@wwaluminum.com

📱 WhatsApp: +86 15736973771

🏭 Worthwill Aluminum – Reliable Anodised Aluminium Sheet Supplier

Contact us today for a free quote and sample. Let’s power your next project with premium anodised aluminum!