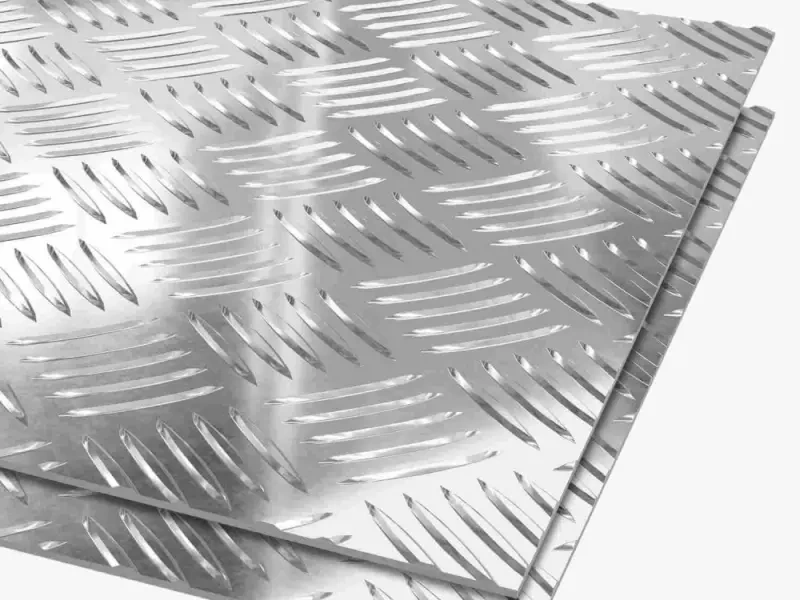

Aluminum checkered plate, also widely known as aluminum tread plate or diamond plate, is a highly versatile material known for its distinctive raised pattern. This pattern provides excellent grip, making it a popular choice for safety flooring and decorative purposes. From industrial settings to modern architecture, the demand for high-quality aluminum checkered plate continues to grow.

Finding the right aluminum checkered plate manufacturer is crucial for ensuring product quality, reliability, and cost-effectiveness for your specific project needs.

1. What Makes Aluminum Checkered Plate a Preferred Material?

The unique properties of aluminum checkered plate contribute to its widespread use across various industries. Understanding these benefits is key to appreciating its value.

1.1 Key Advantages of Aluminum Tread Plate

- Lightweight and Strong: Aluminum is significantly lighter than steel, which simplifies handling and installation. Despite its low weight, it offers excellent strength-to-weight ratio, ensuring structural integrity in many applications. This feature also helps reduce fuel consumption in transportation applications.

- Corrosion Resistance: One of aluminum’s standout features is its natural resistance to corrosion. When exposed to air, aluminum forms a thin, protective oxide layer that prevents further rust and degradation. This makes aluminum checkered plate ideal for outdoor, marine, and high-humidity environments without requiring constant maintenance.

- Non-Slip Surface: The raised pattern on aluminum checker plate provides superior traction, drastically reducing the risk of slips and falls. This critical safety feature is invaluable in industrial walkways, ramps, stairs, and vehicle steps.

- Durability and Longevity: Thanks to its inherent properties and robust design, aluminum tread plate can withstand heavy use, impacts, and harsh conditions, leading to a long service life and reduced replacement costs.

- Aesthetic Appeal: Beyond functionality, the bright, reflective surface of aluminum checkered plate offers a modern and clean look. It can be used for decorative purposes or left in its natural state, adding a contemporary touch to various designs.

- Easy to Fabricate: Aluminum is relatively easy to cut, drill, bend, and weld, allowing for flexible fabrication and customization to meet diverse project requirements.

2. Key Considerations When Selecting an Aluminum Checkered Plate Manufacturer

Choosing the best aluminum checkered plate manufacturer is vital for the success of your project. Here are the main factors to evaluate:

2.1 Quality Standards and Certifications

A reputable aluminum checkered plate manufacturer will adhere to strict quality control measures and international standards (e.g., ISO 9001). Look for suppliers that provide material test certificates, ensuring their products meet specific alloy compositions, mechanical properties, and dimensional tolerances. This guarantees the consistency and performance of the aluminum tread plate.

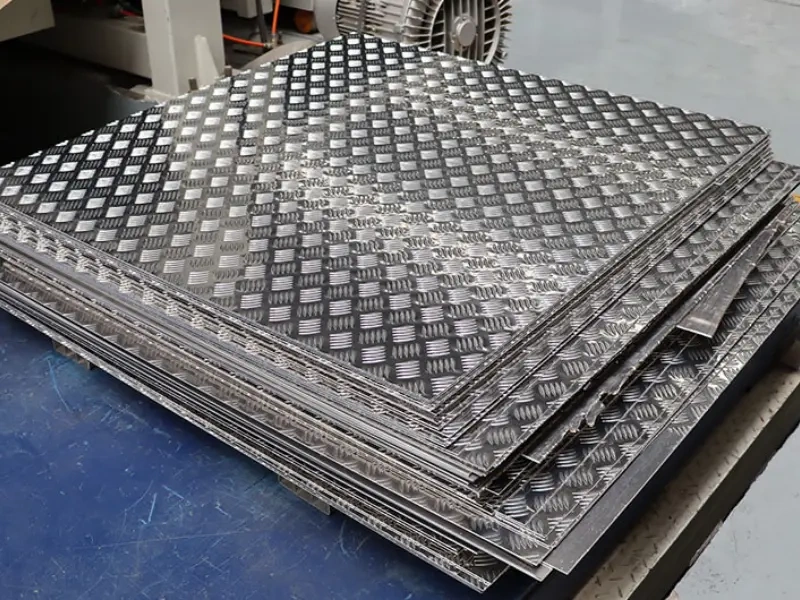

2.2 Production Capabilities and Technology

Assess the manufacturer’s capacity to produce the volume and specific types of aluminum checkered plate you need. Modern manufacturing facilities with advanced cutting, forming, and finishing equipment often indicate higher quality and efficiency. Inquire about their ability to handle custom sizes or unique patterns.

2.3 Product Range and Customization Options

A good aluminum plate supplier should offer a wide selection of alloys, patterns, thicknesses, and sizes. The ability to provide custom cuts, special alloys (like marine-grade aluminum), or specific surface finishes can be a significant advantage, especially for specialized applications.

2.4 Customer Service and Support

Excellent communication, responsive technical support, and strong after-sales service are indicators of a reliable aluminum checkered plate manufacturer. They should be able to assist with product selection, technical queries, and logistics.

2.5 Pricing and Lead Times

While cost is always a factor, it should be balanced with quality and delivery reliability. Compare quotes from several aluminum tread plate suppliers, considering their lead times and ability to meet your project deadlines. A lower price might not always be the best value if it compromises quality or causes delays.

3. Understanding Aluminum Checkered Plate Types and Specifications

Aluminum checkered plate comes in various forms, differentiated by alloy, pattern, and dimensions. Here’s a breakdown of common types and their digitalized specifications:

3.1 Common Aluminum Alloys Used

| Alloy Series | Key Characteristics | Typical Applications |

|---|---|---|

| 1xxx (e.g., 1050, 1060) | Pure aluminum, excellent corrosion resistance, good workability, lower strength. | General purpose, chemical equipment, decorative. |

| 3xxx (e.g., 3003, 3105) | Aluminum-manganese alloy, good formability, moderate strength, excellent corrosion resistance. | Flooring, decorative panels, general fabrication. |

| 5xxx (e.g., 5052, 5083, 5754) | Aluminum-magnesium alloys, high strength, excellent marine corrosion resistance, good weldability. | Marine applications, vehicles, heavy-duty flooring. |

| 6xxx (e.g., 6061) | Aluminum-magnesium-silicon alloy, good strength, weldability, heat-treatable. | Structural components, frames. |

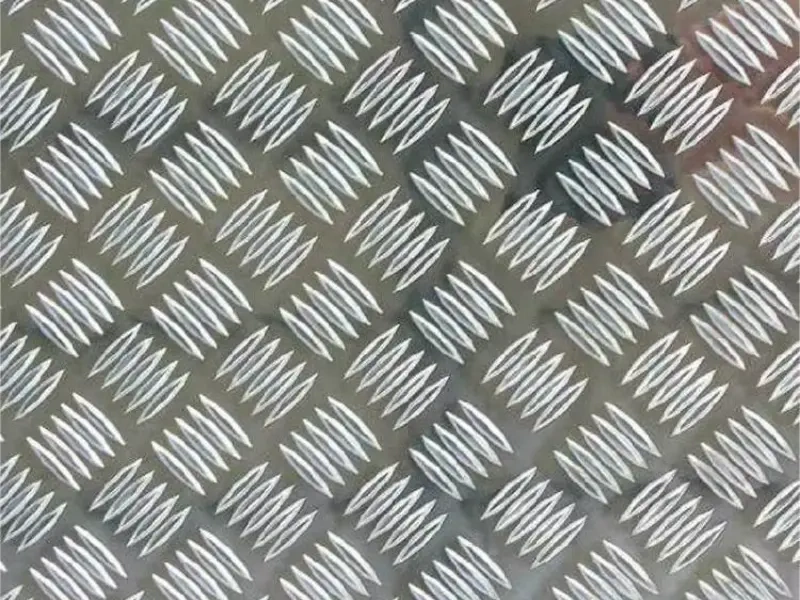

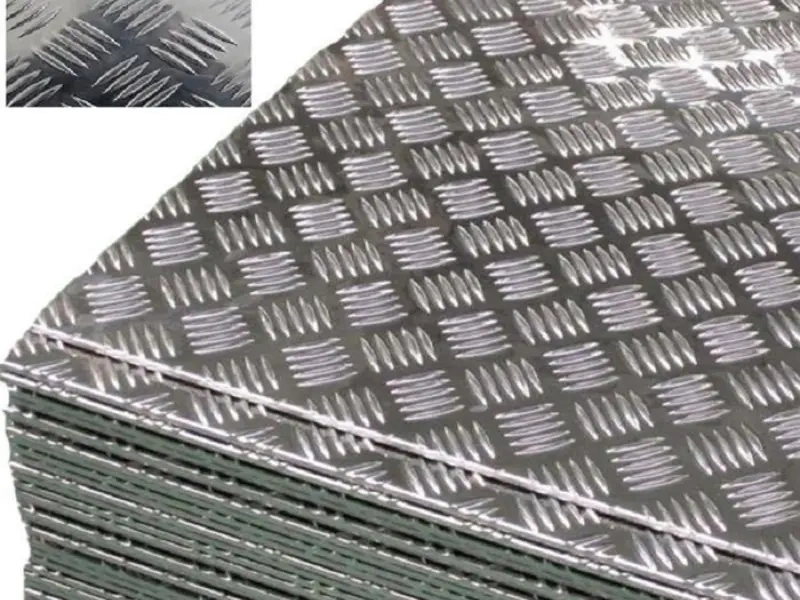

3.2 Common Tread Patterns

The pattern is crucial for anti-slip properties and aesthetics.

| Pattern Type | Description | Primary Use |

|---|---|---|

| One Bar (Diamond Plate) | Single, elongated raised lines. | Light-duty flooring, decorative. |

| Two Bar | Two parallel raised bars. | Moderate grip applications. |

| Three Bar | Three parallel raised bars. | Industrial flooring, steps, higher grip needs. |

| Five Bar (Propeller Pattern) | Five parallel raised bars, most common. | Excellent anti-slip, heavy-duty industrial, transport. |

3.3 Digitalized Specifications (Typical Ranges)

When ordering aluminum checkered plate, specific dimensions are critical. Here are typical ranges:

| Specification | Metric Range (mm) | Imperial Range (inches) |

|---|---|---|

| Thickness | 1.0 – 10.0 | 0.039 – 0.394 |

| Width | 1000 – 2000 | 39.37 – 78.74 |

| Length | 2000 – 6000 (or custom) | 78.74 – 236.22 (or custom) |

| Temper | H114, H22, H24, H32, H34, O | (Industry standards) |

4. Diverse Applications of Aluminum Checkered Plate

The robust features of aluminum checkered plate make it suitable for a vast array of applications across numerous sectors:

- Transportation Industry:

- Truck and trailer beds, toolboxes

- Bus and train steps, flooring

- Ambulance and fire truck platforms

- Marine vessel decking, gangways, and ship interiors

- Industrial Environments:

- Factory flooring, walkways, ramps, and stair treads

- Machine platforms and workbenches

- Mezzanine flooring and anti-slip surfaces in warehouses

- Kick plates and protective coverings

- Architectural and Decorative Uses:

- Wall cladding, column covers

- Decorative panels and interior design elements

- Exhibition booth construction and display stands

- Commercial and Retail Settings:

- Non-slip ramps for wheelchairs and entryways

- Flooring in high-traffic areas

- Checkout and service counter surfaces

- Automotive Aftermarket:

- Custom car and truck accessories

- Protective panels and interior trim

- Construction:

- Temporary walkways and scaffolding platforms

- Trench covers and structural elements

- Aerospace:

- Lightweight internal flooring and structural components.

5. Finding the Right Aluminum Tread Plate Supplier

To locate the ideal aluminum checkered plate manufacturer, consider these strategies:

- Online Research and Industry Directories: Utilize search engines with terms like “best aluminum checkered plate manufacturers,” “aluminum tread plate suppliers,” or “custom aluminum checker plate.” Check B2B platforms and metal industry directories.

- Industry Trade Shows and Exhibitions: Attending these events allows you to meet manufacturers directly, see their products, and discuss your specific needs. It’s an excellent way to network and assess potential suppliers.

- Request for Quotation (RFQ) Process: Prepare a detailed RFQ specifying your required alloy, pattern, dimensions, quantity, and delivery timeline. Send it to a shortlist of potential aluminum plate suppliers to compare their offers accurately.

- Sample Requests: For critical applications, always request product samples. This allows you to evaluate the quality, finish, and pattern of the aluminum checkered plate firsthand before placing a large order.

- Check References and Case Studies: A reliable aluminum checkered plate manufacturer should be able to provide customer references or demonstrate their capabilities through case studies of successful projects.

- Facility Visits: If feasible for a significant order, visiting the manufacturer’s facility can provide valuable insight into their production processes, quality control measures, and overall operational professionalism.