When searching for aluminium sheet price per sq ft, many buyers want clear details about thickness, alloy types, and packaging options. Aluminium sheets are widely used in construction, decoration, automotive, and industrial projects because of their light weight, corrosion resistance, and cost-effectiveness. The price per square foot usually depends on alloy grade, thickness, surface finish, and market conditions.

Classification of Aluminium Sheets

| Classification | Description | Common Use Cases |

|---|---|---|

| Plain Aluminium Sheet | Smooth surface, easy to cut and bend | Roofing, wall panels, cladding |

| Anodized Sheet | Surface treated, anti-corrosion finish | Decorative panels, signage, kitchen use |

| Embossed Sheet | Textured pattern for anti-slip | Flooring, wall protection, insulation |

| Coated Sheet | Painted or color-coated surface | Advertising boards, interior decoration |

Thickness Options

| Thickness (mm) | Price Impact | Suggested Applications |

|---|---|---|

| 0.5 – 1.0 mm | Lower price per sq ft | Signage, cladding, lightweight panels |

| 1.0 – 2.0 mm | Medium price | Roofing, automotive, building panels |

| 2.0 – 3.0 mm | Higher price | Industrial flooring, kitchen equipment |

| 3.0 – 6.0 mm | Premium price | Heavy-duty structures, aerospace use |

Note: The price per sq ft increases as thickness goes up.

Common Alloys for Aluminium Sheets

| Alloy | Features | Typical Applications |

|---|---|---|

| 1100 | Excellent corrosion resistance, soft metal | Roofing, siding, utensils |

| 3003 | Better strength, anti-rust, workable | Construction, kitchen panels |

| 5052 | High corrosion resistance, marine-grade | Boat panels, tanks, marine equipment |

| 6061 | Strong, heat-treatable, durable | Aerospace, automotive, structural use |

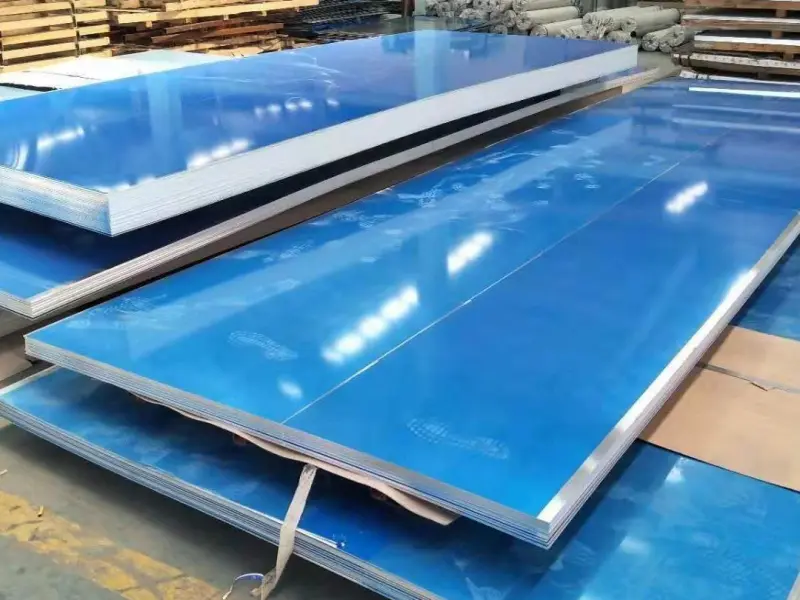

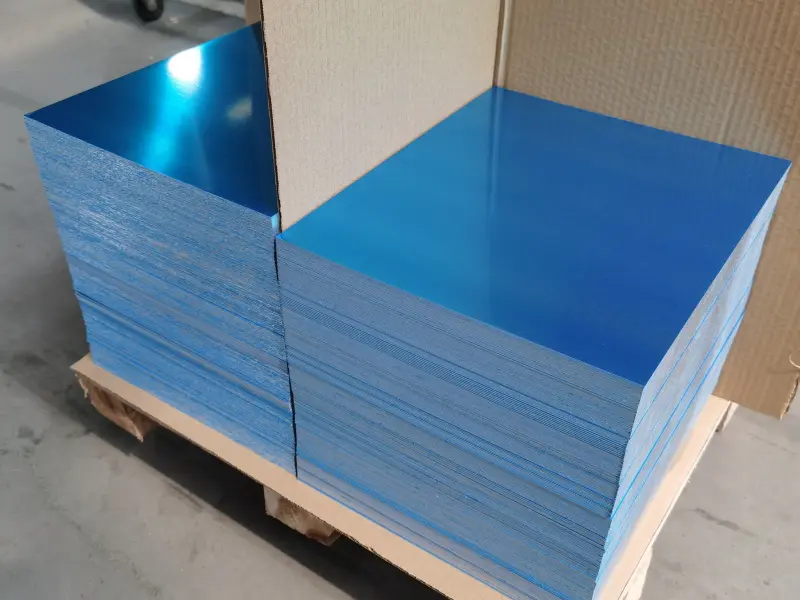

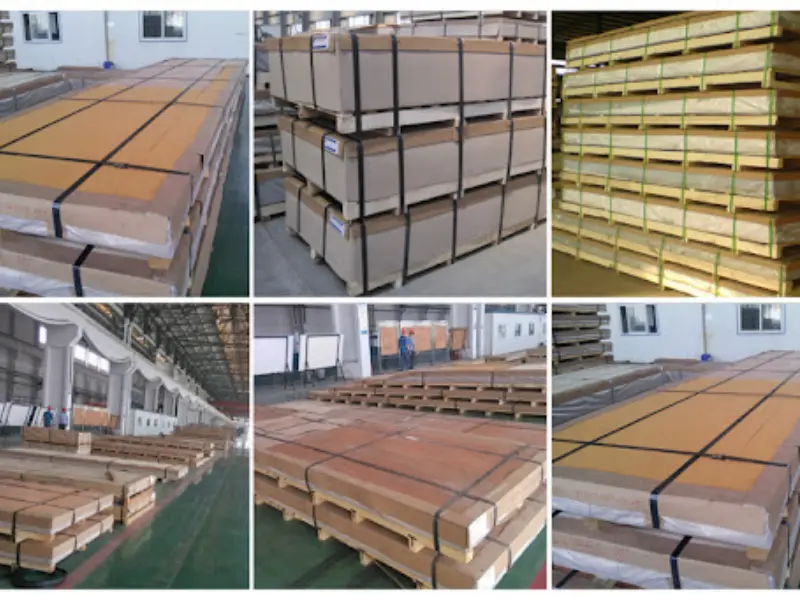

Packaging of Aluminium Sheets

To maintain quality during transport and storage, aluminium sheets are usually packed as follows:

- Protective film on the sheet surface to avoid scratches

- Kraft paper or waterproof paper between sheets

- Wooden pallets or wooden cases for export packaging

- Straps and steel bands for secure handling

- Customized packaging available on request

Factors Affecting Aluminium Sheet Price per Sq Ft

Several key factors influence the price per square foot:

- Alloy type (higher grades like 6061 cost more than 1100)

- Thickness and size (thicker sheets = higher price per sq ft)

- Surface treatment (anodized or coated sheets cost more)

- Market demand and supply (aluminium ingot price trends)

- Order quantity (bulk orders may lower unit price)

Applications of Aluminium Sheets

Aluminium sheets are used across multiple industries thanks to their lightweight and durability.

- Construction & Architecture

- Roofing sheets

- Wall cladding

- Ceilings and decorative panels

- Transportation

- Automotive body panels

- Truck trailer flooring

- Aerospace structural parts

- Industrial & Manufacturing

- Machinery parts

- Storage tanks

- Packaging industry

- Household & Commercial Use

- Kitchen utensils

- Appliances

- Signage and advertisement boards

Sample Aluminium Sheet Price per Sq Ft (Reference Only)

| Thickness (mm) | Alloy | Estimated Price per Sq Ft (USD) |

|---|---|---|

| 0.8 mm | 1100 | $1.50 – $2.00 |

| 1.5 mm | 3003 | $2.20 – $2.80 |

| 2.0 mm | 5052 | $3.50 – $4.20 |

| 3.0 mm | 6061 | $4.80 – $6.00 |

Note: Prices vary by region, supplier, and market.

Price by Alloy Type (per sq ft for 1.0mm thickness)

| Alloy | Characteristics | Price Range ($/sq ft) |

|---|---|---|

| 1100 | Pure aluminium, soft | $2.00 – $3.00 |

| 3003 | Manganese added, general purpose | $2.50 – $3.50 |

| 5052 | Magnesium added, marine grade | $3.00 – $4.50 |

| 6061 | Structural, heat-treatable | $3.50 – $5.00 |

| 7075 | Aerospace grade, very strong | $6.00 – $9.00 |

Advantages of Buying Aluminium Sheets

- Lightweight but strong

- Rust-proof and weather-resistant

- Easy to cut, bend, and weld

- Long service life

- 100% recyclable and eco-friendly

Tips for Buying Aluminium Sheets

To get the best value for your money:

- Compare quotes from multiple suppliers.

- Consider buying in bulk to reduce the price per sq ft.

- Choose the right alloy and thickness for your project to avoid over- or under-specifying.

- Check for supplier certifications (e.g., ISO) to ensure quality.

FAQ

Q: Why does thickness affect price so significantly?

A: Thicker sheets require more raw material and processing time

Q: How often do prices change?

A: Typically monthly, based on LME (London Metal Exchange) rates

Q: Are there additional hidden costs?

A: Yes – transportation, processing, and potential import duties

Q: Can I negotiate prices?

A: Yes, especially for large quantities and repeat business

Q: What’s the minimum order quantity?

A: Usually 1-2 sheets for retail, but prices are higher