What is 3003 Aluminium Alloy Foil?

3003 aluminium alloy foil is a manganese-enriched variant of commercial-grade aluminum, known for its balanced strength, formability, and corrosion resistance. With 1.2% manganese content, it outperforms 1100 aluminum in durability while retaining excellent workability. This foil is widely used in packaging, heat exchangers, and construction due to its cost-effectiveness and adaptability.

About 3003 Aluminium Foil

Google prioritizes content that answers user intent clearly. By addressing common queries like:

- “What are the specs of 3003 aluminum?”

- “How does 3003 compare to 8011 aluminum?”

- “Best uses for 3003 aluminum foil,”

3003 Aluminium Alloy Foil Specifications

- Alloy Composition: 98.4% aluminum, 1.2% manganese, trace iron

- Temper Options: H14, H16, H18, H22 (affects hardness)

- Thickness Range: 0.006mm–0.2mm

- Standards: ASTM B209, GB/T 3880.1

This alloy’s enhanced tensile strength (150–250 MPa) makes it ideal for moderate-stress applications like bottle stoppers and flexible ducting.

Key Properties That Define 3003 Aluminium Foil

- Corrosion Resistance: Oxidation-resistant in humid/wet environments

- Formability: Easy to bend, fold, or emboss

- Thermal Conductivity: Efficient heat distribution (205 W/m·K)

- Non-Magnetic & Non-Toxic: Safe for food packaging

Unlike 5052 aluminum (used in marine settings), 3003 aluminum foil lacks saltwater resistance but excels in cost-efficient, indoor applications.

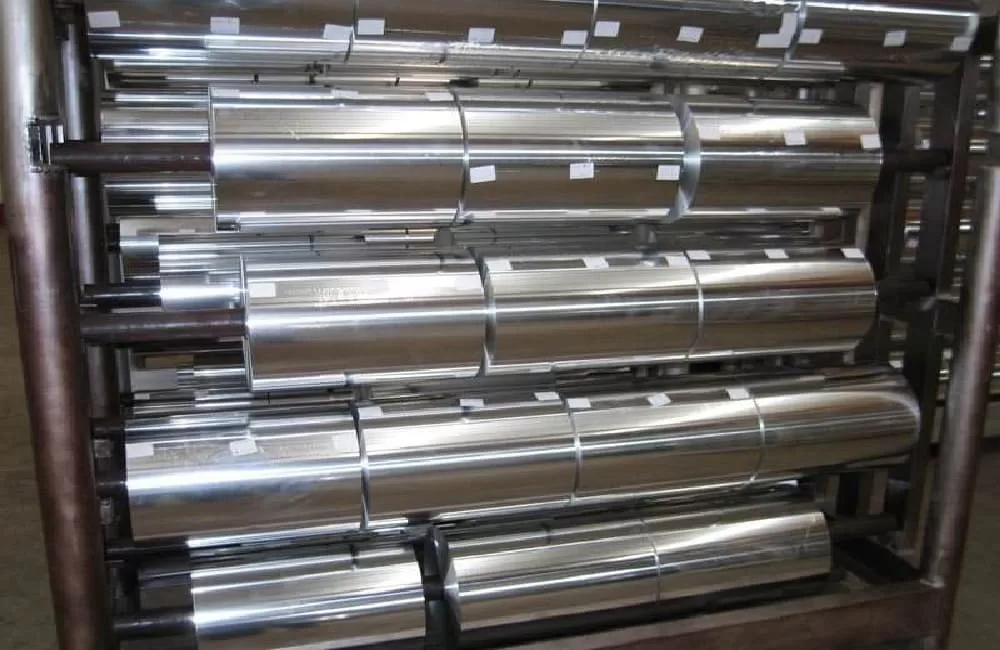

Manufacturing Process of 3003 Aluminum Foil

Production involves:

- Melting: Aluminum ingots mixed with manganese.

- Rolling: Hot-rolled into sheets, then cold-rolled to thin gauges.

- Annealing: Softens metal for flexibility.

- Cutting: Precision slitting to customer specifications.

This process ensures consistent thickness and zero defects, critical for industries like pharmaceuticals requiring sterile packaging.

Benefits of Choosing 3003 Aluminum Alloy Foil

Cost-Effective: Lower price than high-alloy foils

Easy to Print: Matte finish accepts ink well

Eco-Friendly: 100% recyclable

Durable: Resists tearing and fatigue

Businesses saving on materials without sacrificing performance often opt for 3003 aluminum foil over premium grades.

3003 Aluminum Foil Applications (Using Bullet Points for SEO)

Common industries leveraging 3003 aluminum alloy foil include:

- Packaging:

- Food containers, candy wraps, and medical blister packs

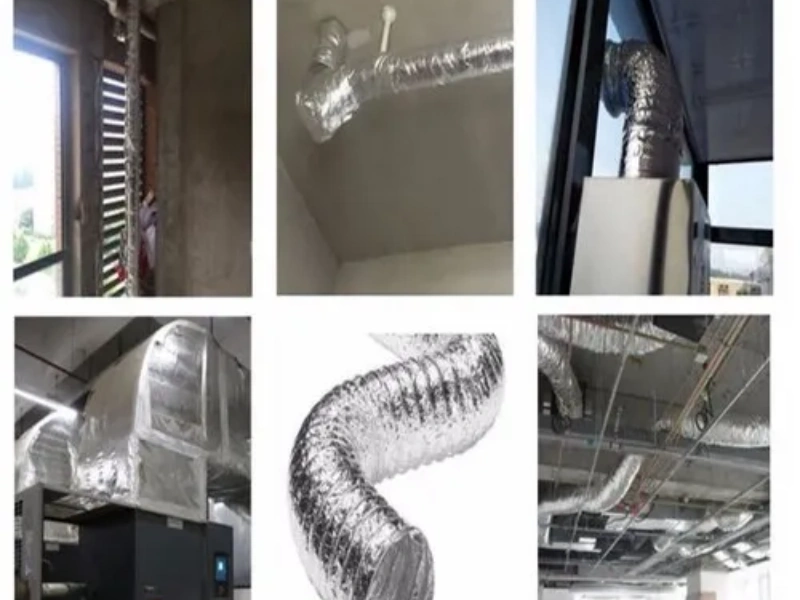

- Construction:

- Roof insulation, HVAC ducts, and wall cladding

- Electronics:

- Capacitor foil for radios and smartphones

- Automotive:

- Radiator fins and under-hood components

- Household:

- Cooking foil and insulation wraps

Bullet points improve scannability, helping Google index key terms like “aluminum foil packaging uses.”

Why 3003 Aluminum Foil Beats Competitors

- Versus 8011 Aluminum Foil: 3003 offers better tear resistance for heavy-duty packaging.

- Versus 1235 Aluminum Foil: Enhanced deep-drawing capacity for complex shapes.

- Versus Steel: Lighter weight reduces shipping costs.

Highlighting comparisons answers user questions like “What is 3003 aluminum used for vs. other alloys?”

Choosing the Right Thickness for Your Needs

Thickness impacts application suitability:

- 0.006–0.02mm: Flexible for wrapping and laminating

- 0.02–0.1mm: Rigid enough for bottle caps and gaskets

- 0.1–0.2mm: Industrial uses like heat sinks

Consult suppliers to match your 3003 aluminum alloy foil thickness to project demands.

FAQ: Top Questions About 3003 Aluminum Foil

Q: Is 3003 aluminum foil food-safe?

A: Yes! It meets FDA standards for direct contact with edibles.

Q: Can 3003 withstand high temperatures?

A: Operates safely up to 400°C (752°F) without warping.

Q: How to store 3003 aluminum coils?

A: Keep in a dry, ventilated warehouse to prevent moisture damage.

Answering FAQs improves E-E-A-T (Experience, Expertise, Authority, Trust) scores for SEO.

The Go-To Material for Everyday and Industrial Use

3003 aluminum alloy foil combines affordability, versatility, and reliability. Whether for packaging chocolates or insulating buildings, this alloy delivers value across sectors. Prioritize this material when seeking durable, lightweight, and budget-friendly solutions.