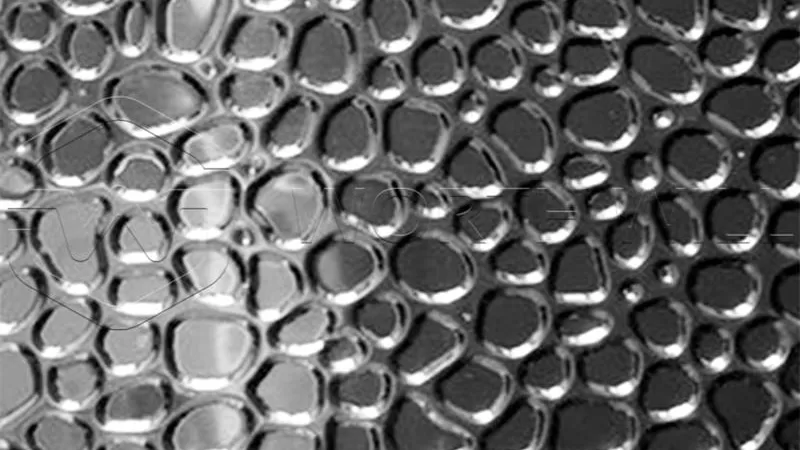

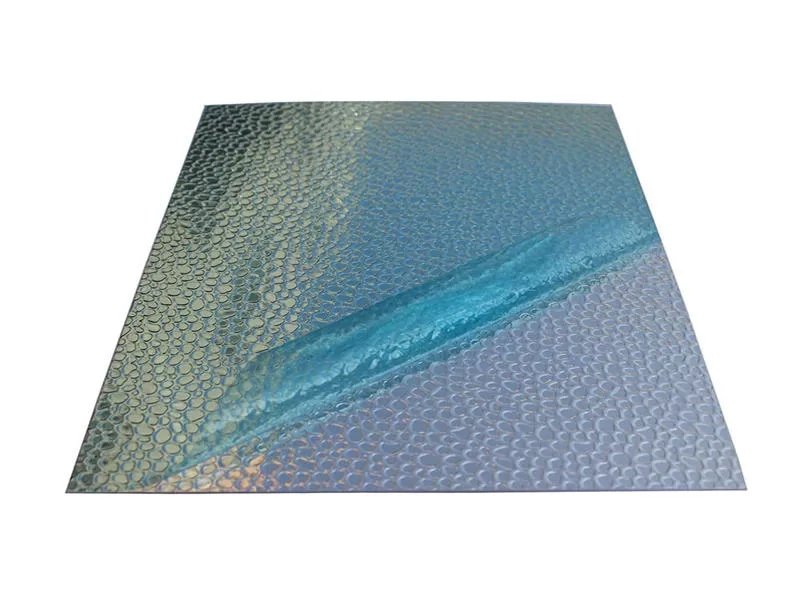

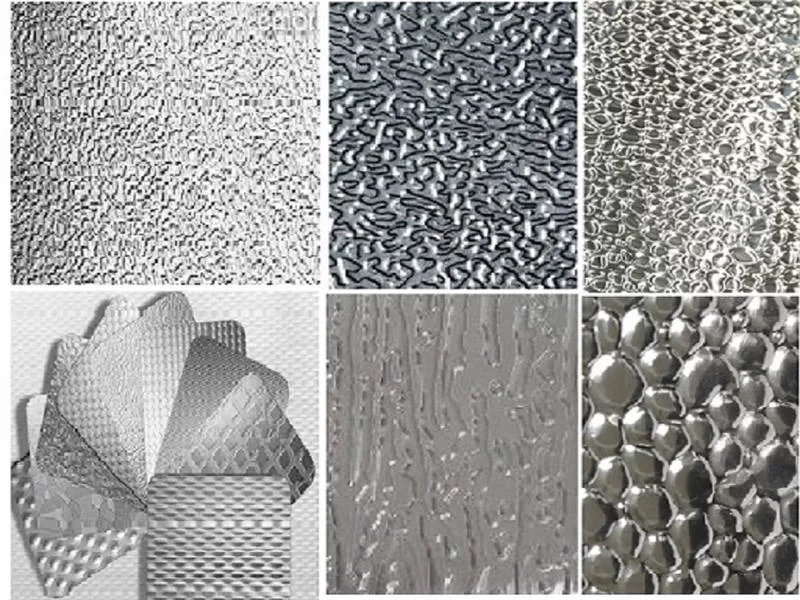

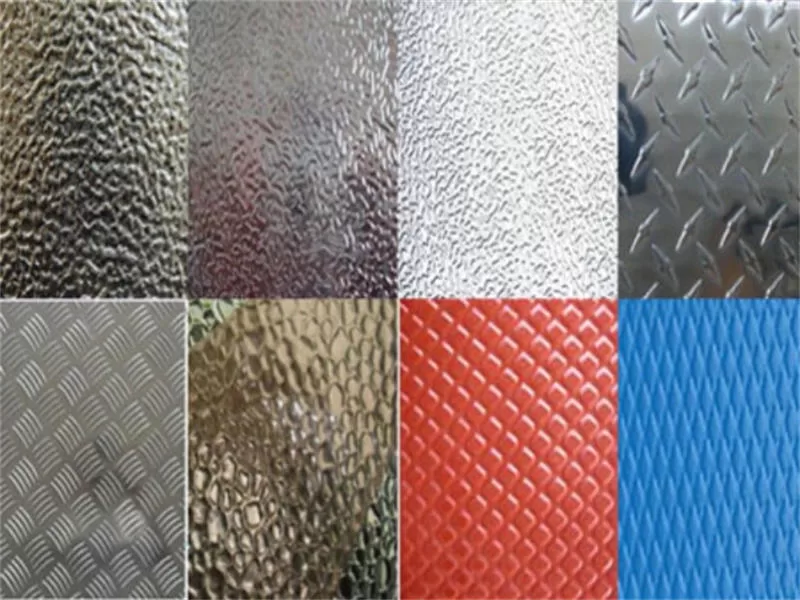

Hammered embossed aluminum is a versatile and visually striking material, widely used in various industries for both its aesthetic appeal and functional benefits. Its unique textured surface, reminiscent of traditional hand-hammered metal, offers a distinctive look that can enhance any project.

Key Specifications of Hammered Embossed Aluminum

| Specification | Description | Common Types/Ranges |

|---|---|---|

| Classification (Pattern) | The specific texture applied to the surface. | Hammered Embossed (distinctive irregular dimpled texture). |

| Thickness | The gauge or depth of the aluminum sheet. This affects durability, weight, and ease of forming. | 0.2 mm to 3.0 mm (0.008 inches to 0.118 inches). Commonly used thicknesses are 0.3 mm, 0.5 mm, 0.8 mm, 1.0 mm, 1.2 mm. |

| Alloy | The specific blend of aluminum with other elements that determines its mechanical and chemical properties. | 1050, 1060, 1100 (Commercially pure for good formability, corrosion resistance), 3003 (Manganese alloy for moderate strength), 5052 (Magnesium alloy for higher strength and excellent corrosion resistance). |

| Width | The dimension across the coil or sheet. Varies based on manufacturing capabilities and application needs. | 500 mm to 1500 mm (20 inches to 60 inches). Custom widths are often available. |

| Temper | The hardness and strength of the aluminum, achieved through heat treatment or work hardening. | H14, H16, H18, H22, H24, H26 (Work-hardened tempers, offering varying levels of rigidity and ductility). |

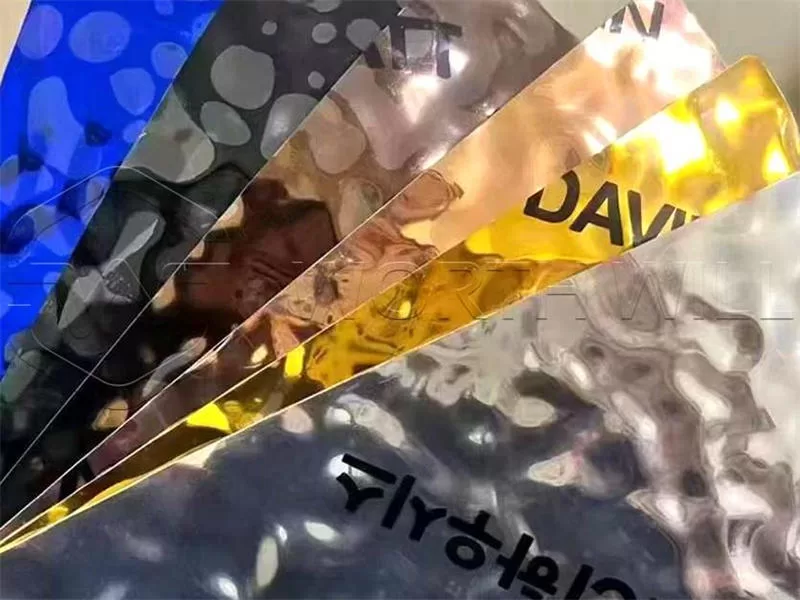

| Surface Finish | Refers to the overall appearance beyond the embossed pattern, including any coatings or treatments. | Mill Finish (raw aluminum), Bright Finish, Color Coated (e.g., PE, PVDF in various colors like white, black, silver, bronze, blue, green). |

| Coil ID (Inner Diameter) | The diameter of the core on which the coil is wound. Important for unwinding equipment compatibility. | 76 mm, 152 mm, 300 mm, 400 mm, 505 mm (3 inches, 6 inches, 12 inches, 16 inches, 20 inches). |

| Coil OD (Outer Diameter) | The total diameter of the wound coil. Influences handling and storage requirements. | Up to 1200 mm (48 inches), or as specified by customer. |

| Coil Weight | The total weight of a single coil. This impacts logistics, shipping costs, and handling. | From 500 kg to 5000 kg (1100 lbs to 11000 lbs), depending on thickness and width. |

Alloy Considerations for Hammered Embossed Aluminum

The choice of aluminum alloy significantly influences the performance of your hammered embossed aluminum.

- 1xxx Series (e.g., 1050, 1060, 1100): These are known for their high ductility, excellent corrosion resistance, and good thermal conductivity.

- 3xxx Series (e.g., 3003, 3004): Alloyed with manganese, these offer moderate strength and good workability. 3003 is a very common and versatile alloy for hammered embossed aluminum due to its balance of properties.

- 5xxx Series (e.g., 5052, 5754): Containing magnesium, these alloys provide higher strength and superior corrosion resistance, particularly in marine or humid environments. They are suitable for more demanding structural or exterior applications.

Packaging for Safe Delivery

Proper packaging is paramount to ensure your hammered embossed aluminum arrives in perfect condition, free from damage during transit. Leading hammered embossed aluminum suppliers utilize robust packaging methods:

- Eye to Sky Packaging: Coils are placed vertically with the core facing upwards on a sturdy wooden pallet, secured with steel straps. Often used for narrower coils.

- Eye to Wall Packaging: Coils are laid horizontally on a wooden pallet, with the core facing horizontally.

- Standard Export Seaworthy Packaging: This comprehensive packaging typically includes strong wooden pallets or cases, waterproof paper, plastic film wrapping, and often desiccants to prevent moisture damage during long-distance or overseas shipping.

- Custom Packaging: Some hammered embossed aluminum suppliers offer bespoke packaging solutions tailored to specific client needs or unique shipping requirements.

Applications of Hammered Embossed Aluminum

The distinct aesthetic and functional properties of hammered embossed aluminum make it highly suitable for diverse applications:

- Refrigeration Industry: Widely used for refrigerator liners, freezer panels, and thermal insulation dueaking to its excellent heat dissipation and attractive finish.

- Architectural and Construction: Employed in decorative wall panels, ceiling tiles, column covers, and fascia. Its textured surface adds visual interest and hides imperfections.

- HVAC Systems: Used as jacketing for insulation on ducts and pipes, providing both protection and an appealing finish.

- Transportation: Found in the interior panels of RVs, trailers, buses, and marine vessels for both aesthetic and functional purposes (e.g., easy to clean, durable, non-slip).

- Signage and Displays: Creates eye-catching backdrops or elements for commercial signs, exhibition booths, and retail displays.

- Interior Design and Furniture: Applied as decorative accents on furniture, cabinet inserts, bar fronts, and backsplashes, offering a modern, rustic, or industrial look.

- Solar Panels: Used as a backing material to improve heat dissipation and protect the solar cell.

- Decorative Purposes: Suitable for artistic projects, craftwork, and general decorative items

Does Hammered Aluminum Have Any Value?

Does hammered aluminum have any value? Absolutely, both from a functional and, in some cases, a collectible perspective.

From a functional and aesthetic value standpoint (for newly manufactured hammered embossed aluminum):

- Durability and Performance: It offers enhanced rigidity, corrosion resistance, and lightweight properties, making it valuable for demanding applications where these characteristics are crucial.

- Visual Appeal: The unique hammered texture provides a high-end, distinctive look that adds significant aesthetic value to any product or structure it’s used in. It can elevate the design of interiors, appliances, or architectural features.

- Practical Benefits: Its ability to diffuse light reduces glare, and the pattern effectively conceals minor scratches, smudges, and fingerprints, maintaining its appearance over time. This reduces maintenance and extends the perceived lifespan of the product.

- Market Demand: Due to these benefits, there is consistent market demand for hammered embossed aluminum across various industries, giving it intrinsic commercial value.

From a collectible or vintage value standpoint (for old hammered aluminum items):

- Vintage hammered aluminum pieces, especially those from well-known manufacturers (like Wendell August Forge, or smaller craft studios), can hold significant collector’s value. The value depends on factors such as rarity, condition, craftsmanship, age, and historical significance. These are typically decorative items like trays, bowls, and serving pieces.

What Year Was Hammered Aluminum Popular?

What year was hammered aluminum popular?

The popularity of hammered aluminum as a decorative art form, particularly for household items and gifts, reached its peak in the mid-20th century, specifically from the 1930s through the 1950s. During this period, hammered aluminum items became a widespread and affordable alternative to sterling silver or pewter, offering a handmade look and a touch of elegance to many homes. Companies produced a wide array of items, from trays and bowls to serving dishes and decorative plaques.

Instead, its use has been consistent and continues to evolve in modern manufacturing, construction, and design, driven by its practical benefits and enduring aesthetic appeal. It remains a popular choice today for its unique texture and performance.

Benefits of Choosing Hammered Embossed Aluminum

Opting for hammered embossed aluminum provides a range of benefits for your projects:

- Unique Aesthetic Appeal: The distinctive hammered texture offers a high-end, artistic, and contemporary look that can differentiate products and designs.

- Enhanced Durability: The embossing process increases surface rigidity and helps camouflage everyday wear and tear, improving longevity.

- Lightweight: As an aluminum product, it retains its low weight, making it easy to handle, transport, and install, thereby reducing structural load and labor costs.

- Excellent Corrosion Resistance: Naturally resistant to rust and corrosion, especially with appropriate alloys, making it suitable for both indoor and outdoor use.

- Improved Light Diffusion: The textured surface reduces glare and provides a softer, more uniform reflection of light, beneficial in various environments.

- Easy to Clean and Maintain: The surface is generally easy to wipe down, and the pattern can help hide smudges or light dirt, simplifying upkeep.

- Versatility: Adaptable to a wide array of applications due to its combination of beauty, strength, and functional properties.

Conclusion

Hammered embossed aluminum is a versatile and highly valued material, offering a compelling blend of aesthetic distinction and functional superiority.