Veneer panels are engineered wood products consisting of a thin layer of natural wood (veneer) bonded to a core material like plywood, MDF, or particleboard. While they offer aesthetic appeal and cost-effectiveness, they also come with several disadvantages that users should consider before selecting them for projects.

Key Disadvantages of Veneer Panels

- Susceptibility to Moisture Damage

- Veneer panels are prone to warping, swelling, or delamination when exposed to humidity or water.

- Unsuitable for high-moisture areas like bathrooms or kitchens without proper sealing.

- Durability Limitations

- The thin veneer layer can scratch, dent, or chip easily compared to solid wood.

- Not ideal for high-traffic surfaces or heavy-use furniture.

- Difficulty in Repair

- Damaged veneer is challenging to repair without professional help.

- Sanding or refinishing risks wearing through the thin veneer layer.

- Limited Longevity

- Veneer panels may degrade faster than solid wood, especially if the core material is low-quality.

- Edges and corners are vulnerable to wear over time.

- Formaldehyde Emissions

- Some veneer panels use adhesives containing formaldehyde, which can off-gas and affect indoor air quality.

- Aesthetic inconsistencies

- Natural wood veneer may have variations in color/grain, making it hard to match panels.

- The seam between panels might be visible in large installations.

- Not Eco-Friendly in All Cases

- While veneer uses less wood, some core materials (e.g., MDF) are not biodegradable or sustainably sourced.

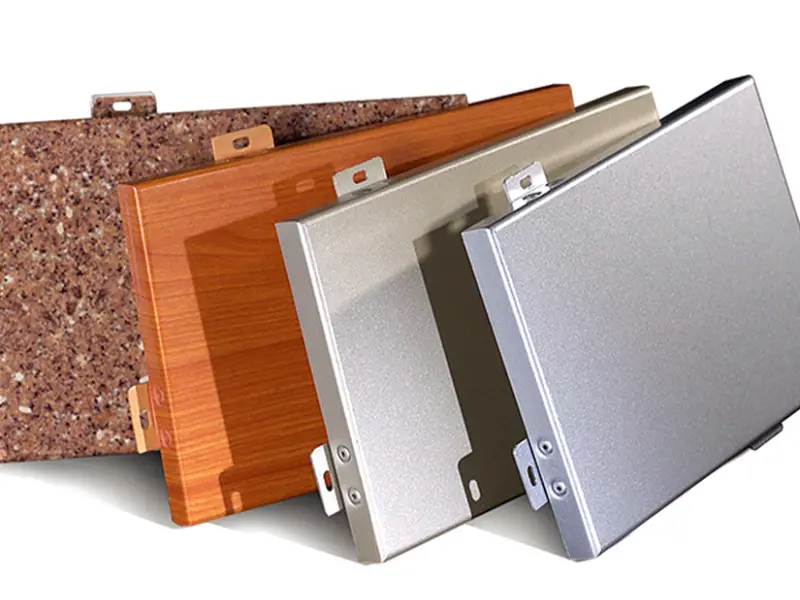

Comparison of Veneer Panel Types and Their Disadvantages

| Panel Type | Core Material | Key Disadvantages | Best Avoided For |

|---|---|---|---|

| Veneer on Plywood | Plywood | Prone to edge splintering, visible layers | Outdoor use, high-moisture areas |

| Veneer on MDF | MDF | Susceptible to water damage, heavy weight | Kitchens, bathrooms |

| Veneer on Particleboard | Particleboard | Low durability, easily damages | High-traffic furniture |

| Veneer on Solid Core | Solid Wood | Expensive, still vulnerable to veneer damage | Budget projects |

Applications Where Veneer Panels Perform Poorly

- High-Humidity Areas: Bathrooms, laundries, or basements.

- Outdoor Use: Decks, fences, or exterior cladding.

- Heavy-Duty Furniture: Tabletops, flooring, or children’s furniture.

- Commercial Spaces: Restaurants, schools, or hospitals with high wear and tear.

How to Mitigate the Disadvantages

- Choose High-Quality Panels: Opt for veneers with waterproof cores (e.g., marine-grade plywood).

- Proper Sealing: Use polyurethane or lacquer coatings to protect against moisture.

- Avoid High-Impact Areas: Use veneer panels for low-traffic applications like decorative walls.

- Regular Maintenance: Clean with dry cloths and avoid abrasive chemicals.

What Are the Disadvantages of Veneer Panels?

While veneer panels offer affordability and aesthetic versatility, their disadvantages—moisture sensitivity, durability issues, and repair challenges—make them unsuitable for certain applications. By understanding these limitations and selecting the right type for low-impact, indoor use, users can maximize their benefits while minimizing risks. For long-term durability, solid wood or alternative materials may be a better investment.