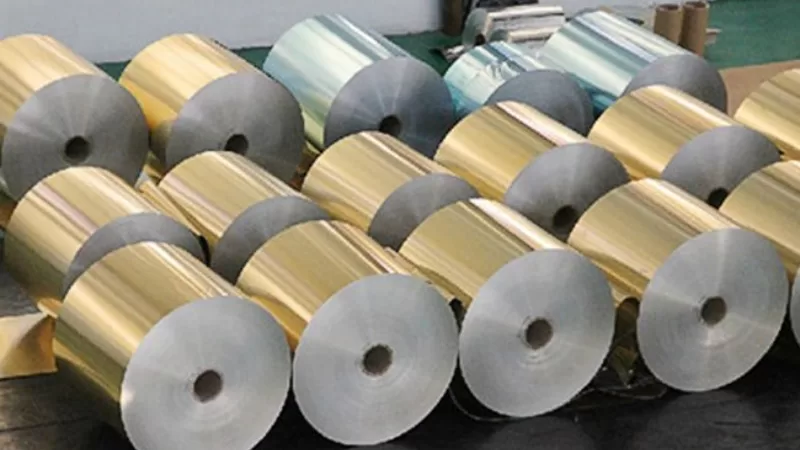

Welcome to the world of high-quality color coated aluminum foil. This versatile material has become essential in many industries. It offers both protection and beauty. As a leading professional manufacturer of color coated aluminum foil, we understand your needs. We provide top-tier products designed for various uses.

What is Color Coated Aluminum Foil?

Color coated aluminum foil is standard aluminum foil with a special paint layer applied to one or both sides. This coating is not just for looks. It adds many benefits. The process involves cleaning the aluminum surface, then applying a primer, followed by a color coat. Finally, a clear finish often protects the color. This creates a strong bond between the paint and the aluminum. The result is a product that is resistant to corrosion, wear, and fading. It also offers excellent insulation and aesthetic appeal.

Specification: Classification

Understanding the different types and features of color coated aluminum foil is key. We classify our products based on several important specifications. This helps you choose the perfect material for your project.

Types of Coatings

The type of coating greatly impacts the foil’s performance and lifespan. We offer various options to meet diverse requirements:

- PE (Polyester) Coated Aluminum Foil: This is a common and affordable choice. PE coatings offer good weather resistance and flexibility. They are suitable for general outdoor and indoor applications. You will often find PE coated foil in roofing or general decoration.

- PVDF (Polyvinylidene Fluoride) Coated Aluminum Foil: PVDF coatings are known for their excellent durability. They resist harsh weather, UV radiation, and chemicals very well. This makes them ideal for long-term outdoor use, such as architectural cladding. When you need extreme longevity, PVDF is the premium option.

- Epoxy Coated Aluminum Foil: Epoxy coatings provide superior adhesion and chemical resistance. They are often used in demanding environments where corrosion protection is vital. This type of coating is common in packaging or industrial applications.

- Other Specialized Coatings: We also provide custom coatings for specific needs. These might include anti-bacterial, high-temperature resistant, or highly reflective finishes.

Alloy and Temper

The base aluminum alloy and its temper affect the foil’s strength and formability.

- Common Alloys: We use various aluminum alloys like 1000 series, 3000 series, and 8000 series. For example, 1050 and 1060 are common for their excellent corrosion resistance and formability. 3003 alloy offers good strength and workability. The choice of alloy depends on the final application.

- Temper: Temper refers to the hardness of the aluminum. Common tempers include O (soft/annealed), H12, H14, H16, H18 (various levels of hard-rolled). An “O” temper color coated aluminum foil is very flexible. It’s easy to bend and shape. Harder tempers like H18 are stronger and more rigid.

Thickness and Width

Our color coated aluminum foil comes in a wide range of thicknesses and widths.

- Thickness: Typically, thicknesses range from 0.02mm to 0.5mm. Thinner foils are good for flexible packaging. Thicker foils are used in construction or automotive parts.

- Width: We can supply rolls or sheets in widths from 50mm up to 2000mm. We also offer custom sizes to perfectly fit your project specifications.

Color and Finish

The aesthetic appeal is a major advantage of color coated aluminum foil.

- Color Options: We offer an almost endless palette of colors. You can choose from standard RAL colors, pantone colors, or even custom colors to match your brand.

- Finish: Available finishes include high gloss, matte, metallic, and even embossed textures. This allows for specific visual effects and added durability.

Why Choose a Professional Manufacturer?

Choosing an experienced and professional manufacturer of color coated aluminum foil is crucial. It ensures you receive high-quality, consistent products.

- Quality Control: A professional manufacturer has strict quality control processes. This guarantees that every batch of color coated aluminum foil meets industry standards.

- Expertise and Technology: We use advanced production lines and have skilled technicians. This allows us to produce precise, high-performance foil efficiently.

- Customization: We can tailor products to your specific needs. This includes custom colors, thicknesses, widths, and coatings.

- Reliability: You can depend on us for consistent supply and on-time delivery. We are a reliable partner for your business.

Key Features and Advantages of Our Color Coated Aluminum Foil:

Our color coated aluminum foil offers many benefits:

- Durability and Longevity: The robust coating protects the aluminum from wear and tear. It ensures a long service life.

- Corrosion Resistance: The coating acts as a barrier against moisture, chemicals, and pollutants. This prevents rust and corrosion.

- Excellent Insulation Properties: Aluminum is a great insulator. When coated, it maintains its thermal and electrical insulation qualities.

- Lightweight: Aluminum is naturally light. This makes the foil easy to handle, transport, and install. It helps reduce overall project weight.

- Easy to Process and Fabricate: It can be cut, bent, stamped, and formed without cracking or peeling. This makes it suitable for various manufacturing processes.

- Aesthetic Appeal: With a wide range of colors and finishes, it adds visual appeal to any product or structure.

- Eco-friendly: Aluminum is 100% recyclable. Using color coated aluminum foil supports sustainable practices.

Applications of Color Coated Aluminum Foil:

The versatility of color coated aluminum foil makes it suitable for numerous industries and applications:

- Construction:

- Roofing and cladding for buildings

- Insulation panels for walls and ceilings

- False ceilings and decorative panels

- Guttering and downpipes

- Packaging:

- Food and beverage containers

- Pharmaceutical packaging

- Cosmetic packaging

- Flexible packaging for various goods

- Automotive Industry:

- Heat shields and insulation for engine components

- Decorative trim parts

- Electronics:

- Capacitor shells

- Heat sinks

- Shielding for cables and components

- HVAC Systems:

- Ductwork insulation

- Air conditioner fins

- Household Goods:

- Appliance panels

- Cookware parts

- Decorative Purposes:

- Signage and display boards

- Art and craft projects

- Interior design elements

Our Commitment to Quality and Innovation:

As a professional manufacturer of color coated aluminum foil, we are dedicated to excellence. We hold various certifications, such as ISO 9001. This shows our commitment to high quality standards. We also invest in research and development. Our goal is to create new and better products. We strive to improve our coating technologies and expand our product range. Our customer support team is always ready to assist you. We aim for complete customer satisfaction.

Contact Us for Your Color Coated Aluminum Foil Needs:

Are you looking for a reliable supplier of color coated aluminum foil? Look no further. We are ready to help you with your specific requirements. Whether you need standard products or custom solutions, our team can provide expert advice. Let us help you choose the best color coated aluminum foil for your next project.

Conclusion:

Color coated aluminum foil is a material of choice for modern applications. Its combination of strength, aesthetics, and durability is unmatched. As a professional manufacturer, we are proud to offer a wide selection of top-quality products. We ensure that our color coated aluminum foil meets the highest industry standards. Choose us as your partner. Experience the difference that quality and expertise can make. We are here to support your success with superior color coated aluminum foil solutions.