How To Polish A Sheet Of Aluminum To Use As A Mirror Finish?

Polishing is a technique of producing a product with a smooth surface using a polishing disc and a polishing agent with the aid of a machine. Especially in metal industry, polishing is very hot in some products such as aluminum sheet.

What Is Polished Aluminum Sheet?

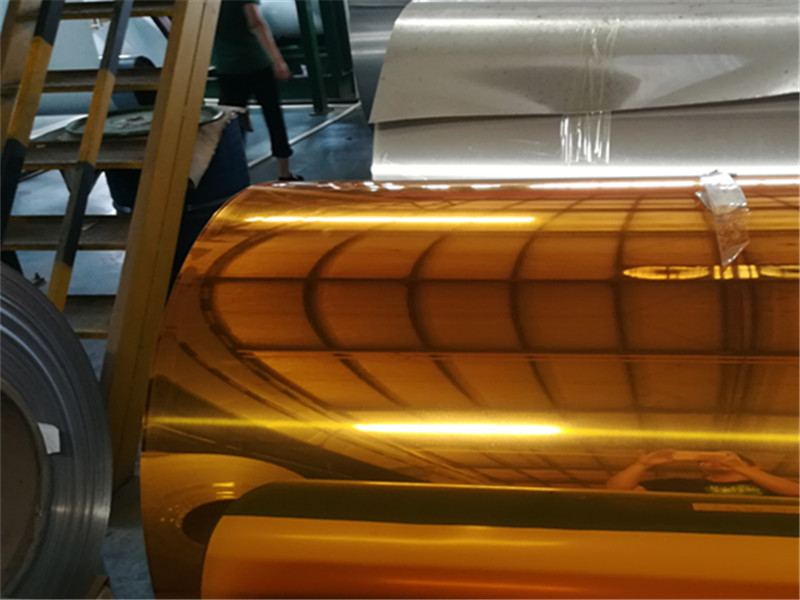

Polished mirror aluminum sheet is also known as mirror aluminum sheet. It refers to the aluminum sheet that is processed by rolling, grinding and other methods to make the surface of the plate show a mirror effect.

Features Of Mirror Aluminum Sheet

- High reflectivity

- Scratch resistant

- Uniform color and the surface oxide layer will never fall off

- Excellent heat dissipation performance, suitable for precision electronic products

- Easy to clean

- Environmentally friendly and non-toxic

Polishing Process

First, the metal itself glows naturally. It’s strong and can be worked into almost anything. That’s to say it also can be polished up to a beautiful mirror finish. But over time, it oxidizes and scratches. Oxidation from scratches prevents light from reflecting back, which can ruin the product’s luster. By polishing, you can remove the oxide layer as well as a very thin layer of the metal itself. Doing so smooths the metal, removes blemishes, and makes it sparkle again.

With the advancement of technology, most factories will choose machine polishing. We only need to adjust the value and position of the machine. Almost no manual handling is required.

In summarize, aluminum sheet coil can be polished by machine. We can adopt plenty of methods and tools to polish metals to reach mirror effect.