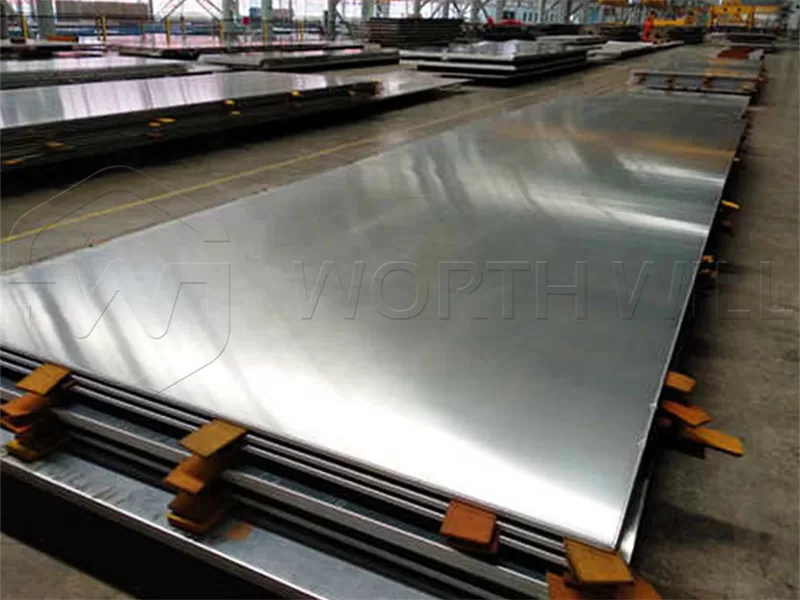

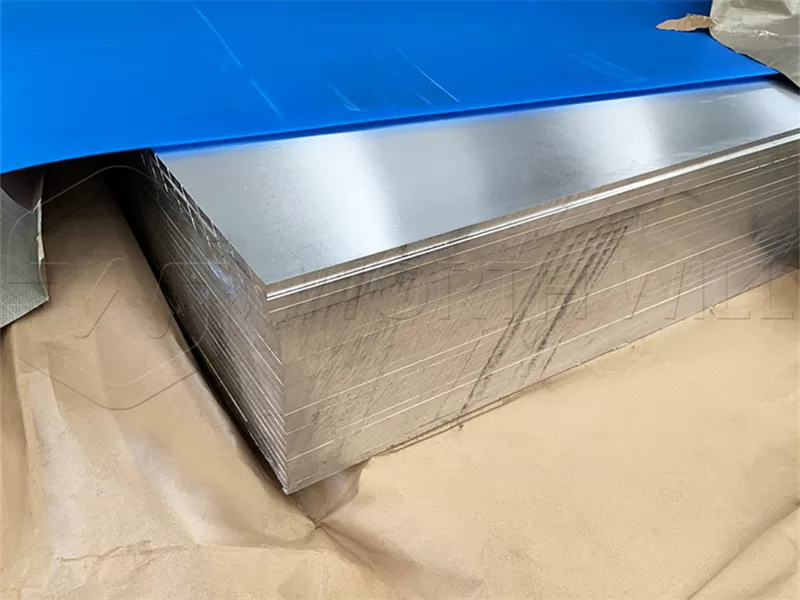

When selecting aluminum for industrial, marine, or structural applications, buy 5052 aluminum plate alloy stands out as one of the most versatile and reliable options. Known for its excellent corrosion resistance, formability, and strength, this alloy is widely used across multiple industries.

We’ll explore the key benefits, properties, and applications of 5052 aluminum plate to help you determine if it’s the right choice for your project.

Key Properties of 5052 Aluminum Plate

5052 aluminum is part of the 5xxx series, which means it contains magnesium (2.2-2.8%) as its primary alloying element. This gives it several advantages:

High Strength-to-Weight Ratio – Stronger than pure aluminum (1050, 1100) while remaining lightweight.

Excellent Corrosion Resistance – Performs well in marine and chemical environments.

Good Formability – Can be easily bent, welded, and machined.

Non-Heat-Treatable – Gains strength through cold working rather than heat treatment.

Weldability – Compatible with common welding techniques (TIG, MIG, spot welding).

Comparison with Other Aluminum Alloys

| Property | 5052 | 6061 | 3003 |

|---|---|---|---|

| Strength | Medium | High | Low |

| Corrosion Resistance | Excellent | Good | Good |

| Formability | Very Good | Moderate | Excellent |

| Weldability | Excellent | Good | Excellent |

| Marine Suitability | Best | Moderate | Good |

Top Reasons to Choose 5052 Aluminum Plate

① Superior Corrosion Resistance

- Ideal for marine applications (boat hulls, docks, offshore structures).

- Resists saltwater, humidity, and industrial chemicals better than 6061.

② Excellent Formability & Workability

- Can be deep drawn, spun, or stamped without cracking.

- Used in fuel tanks, electronic enclosures, and automotive panels.

③ Good Strength Without Heat Treatment

- H32 temper (strain-hardened) offers improved strength.

- Stronger than 3003 but more formable than 6061.

④ Cost-Effective for Many Applications

- More affordable than 6061 when high strength isn’t critical.

- Long lifespan reduces replacement costs.

⑤ Weldability & Fabrication Ease

- Works well with TIG, MIG, and resistance welding.

- No post-weld heat treatment required.

Common Applications of 5052 Aluminum Plate

Marine & Shipbuilding

- Boat hulls, decks, and railings

- Offshore platforms & dock components

Automotive & Transportation

- Fuel tanks, truck bodies

- Aircraft components (non-structural)

Construction & Architecture

- Roofing, wall panels, gutters

- Decorative trim & signage

Industrial & Manufacturing

- Chemical tanks & pressure vessels

- Electronic enclosures & machinery guards

Consumer Goods

- Appliances (refrigerator liners, cookware)

- Lighting fixtures & HVAC components

About 5052 vs. Other Popular Aluminum Alloys

For 5052 vs. 6061

- Choose 5052 if you need better corrosion resistance and formability.

- Choose 6061 if you need higher strength (structural applications).

5052 vs. 3003

- 5052 is stronger and more corrosion-resistant.

- 3003 is cheaper and better for deep drawing.

5052 vs. 5083

- 5083 is stronger (used in heavy-duty marine applications).

- 5052 is more formable and cost-effective for general use.

Where to Buy 5052 Aluminum Plate Alloy?

- Metal suppliers (local or online)

- Specialty aluminum distributors

- Industrial hardware stores

Tip: Check for H32 or H34 tempers for added strength.

Final Verdict: Is 5052 Right for You?

✅ Best for: Marine, automotive, and general fabrication where corrosion resistance and formability matter most.

❌ Not ideal for: High-stress structural parts (use 6061 or 7075 instead).

If you need a durable, weldable, and corrosion-resistant aluminum plate, 5052 is an excellent choice for many industrial and commercial applications.