Stucco embossed aluminum sheet is a popular type of aluminum panel known for its unique texture. Imagine the surface of plaster (stucco) – it has a slightly rough, uneven look.

If you’ve heard terms like “embossed aluminum,” “stucco embossed aluminum,” or “stucco aluminum coil,” they all refer to this versatile product.

What is Stucco Embossed Aluminum?

Let’s break down the name:

- Aluminum Sheet: This is the basic material – a flat panel made from aluminum.

- Embossed: It’s not just a print; it’s a physical change to the surface.

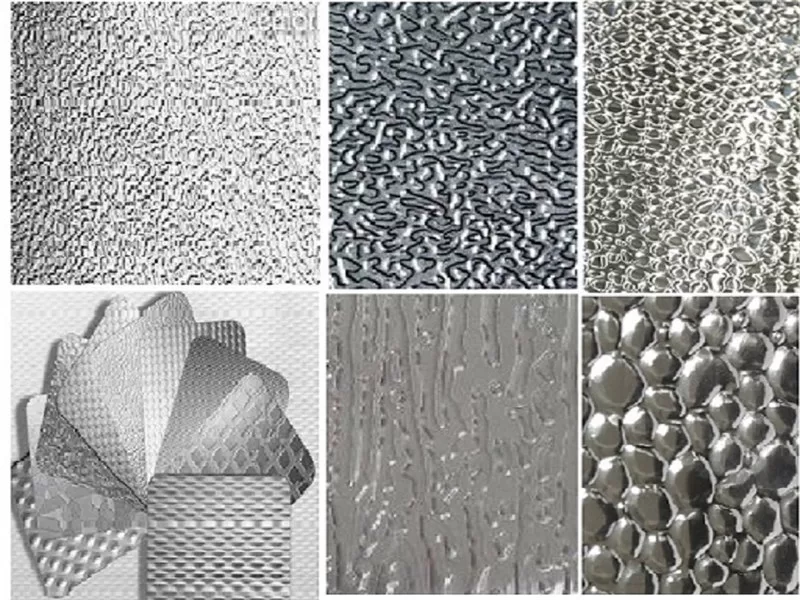

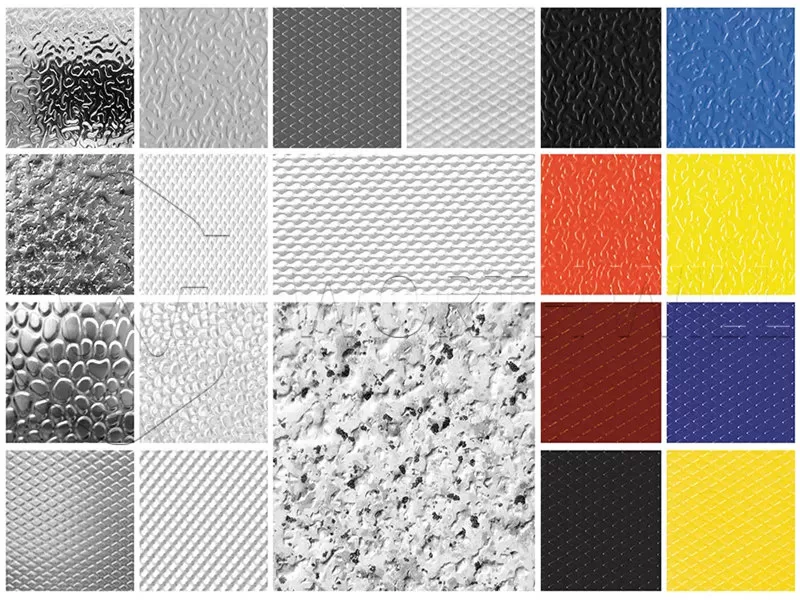

- Stucco: This describes the specific pattern. It’s an irregular, non-directional texture that looks like fine orange peel or plastered wall. This pattern helps to diffuse light, reducing glare, and it also makes the surface more resistant to scratches and fingerprints.

This makes it a decorative aluminum material that is also highly functional. When you see a stucco aluminium sheet, you’re looking at a product designed for both aesthetics and performance.

How Stucco Embossed Aluminum Sheet is Made

The process of creating stucco embossed aluminum sheet is quite straightforward. It involves a special rolling mill. Flat aluminum sheets or coils pass through a set of rollers. One of these rollers has the inverse of the stucco pattern carved into its surface.

Stucco Embossed Aluminum Sheet Specifications

Understanding the specifications of stucco embossed aluminum is important for choosing the right material for your project. Here’s a look at the key details:

| Specification | Description | Common Ranges/Types |

|---|---|---|

| Classification | Stucco embossed aluminum sheets are primarily classified by the aluminum alloy used, the type of stucco pattern, and whether they are in coil or sheet form. | Alloy Series: 1000 series (e.g., 1050, 1060, 1100) for general use; 3000 series (e.g., 3003, 3004) for better strength and corrosion resistance; 5000 series (e.g., 5005, 5052) for marine and high-strength applications. Pattern: Fine stucco, medium stucco. Form: Sheet, Coil. |

| Thickness | This refers to the actual gauge of the aluminum sheet before or after embossing. The embossing process typically has minimal effect on the overall nominal thickness. How thick is a stucco aluminium sheet? Thickness can vary greatly depending on the application. | Commonly ranges from 0.2 mm to 3.0 mm. Thicker sheets are used for structural applications, while thinner ones are used for decorative or insulation purposes. |

| Alloy | The specific aluminum alloy determines the material’s strength, formability, weldability, and corrosion resistance. Popular choices offer a balance of properties. | 1050, 1060, 1100: Good formability, high corrosion resistance, lower strength. Ideal for general-purpose, non-structural applications. 3003, 3004: Medium strength, excellent corrosion resistance, good weldability. Popular for refrigeration and building. 5005, 5052: Higher strength, excellent corrosion resistance, good for marine environments and demanding applications. |

| Packaging | How the stucco embossed aluminum sheet is packed for shipping and storage. Proper packaging prevents damage, scratches, and moisture exposure. | Sheets: Often stacked on wooden pallets, secured with steel straps, and wrapped in waterproof paper or plastic film. Sometimes interleaved with paper to protect the surface. Coils: Wrapped in waterproof paper/plastic, often with wooden or cardboard cores, then strapped and placed on pallets. |

Key Features and Benefits of Stucco Embossed Aluminum Sheet

The unique textured surface of stucco embossed aluminum provides several advantages:

- Aesthetics: The stucco pattern creates an attractive, non-directional finish that can hide minor scratches and fingerprints, making it a good choice for visible applications.

- Reduced Glare: The textured surface diffuses light, reducing reflection and glare compared to smooth aluminum sheets. This is beneficial in areas with strong lighting.

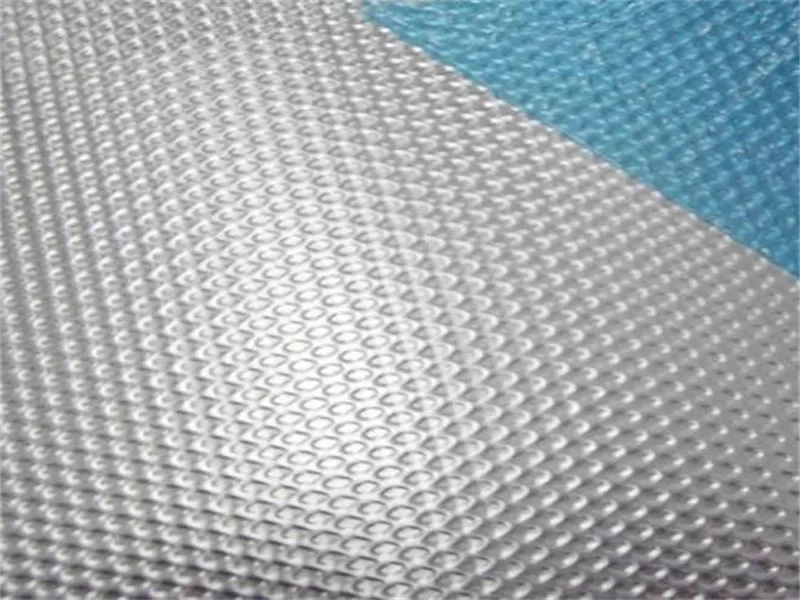

- Increased Surface Area: The embossing slightly increases the surface area, which can subtly improve heat dissipation in certain applications, like refrigerator panels or insulation materials.

- Enhanced Rigidity and Strength: The embossing process stiffens the sheet, making it more rigid than a smooth sheet of the same thickness. This helps reduce “oil canning” (wavy appearance) in large panels.

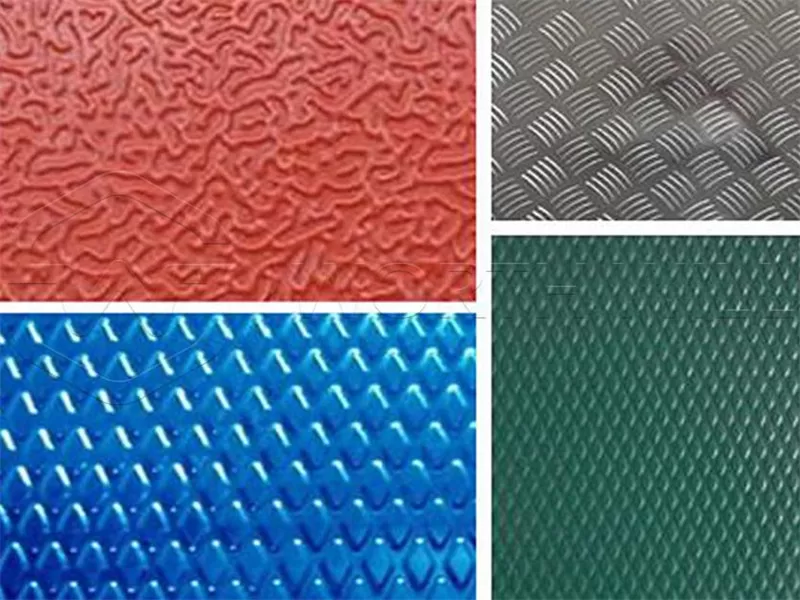

- Anti-Slip Properties: While not as aggressive as diamond plate, the texture provides some anti-slip aluminum properties, making it safer for foot traffic or when handling.

- Corrosion Resistance: Like all aluminum, stucco aluminum sheet offers excellent natural resistance to rust and corrosion, especially when made from alloys like 3003 or 5052.

- Lightweight: Aluminum itself is lightweight, contributing to easier handling, lower transportation costs, and reduced structural loads in applications.

- Easy to Clean: The durable surface is relatively easy to clean and maintain.

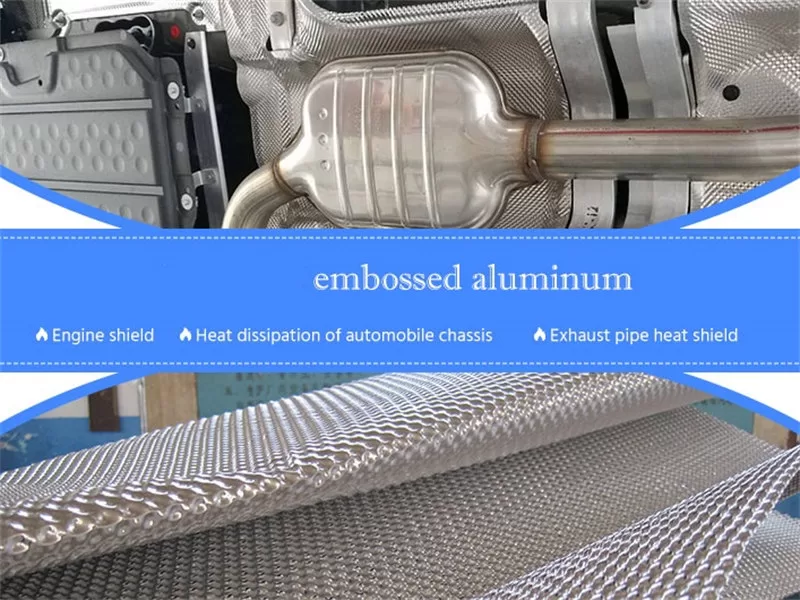

Applications

- Refrigeration Equipment: Widely used for refrigerator panels, freezer linings, and cold room insulation due to its clean appearance, durability, and ability to help with heat dissipation.

- Insulation: Employed in pipe insulation, ductwork, and thermal lagging applications. The increased surface area and textured finish can enhance the efficiency of insulation systems.

- Building and Construction: Used for decorative wall panels, ceiling tiles, column covers, and roofing accents. Its light weight and attractive finish make it ideal for architectural applications.

- Transportation: Found in truck trailers, RVs, and bus interiors as interior liners or exterior cladding due to its durability and lighter weight compared to steel.

- Food Processing Equipment: Applied in parts of food preparation areas, storage units, and display cases because it’s easy to clean and hygienic.

- Elevator Panels: Used for interior decorative panels in elevators due to its scratch resistance and appealing finish.

- Solar Reflectors: In some applications, the diffuse reflection property can be utilized for certain types of solar energy collection.

- Tool Boxes and Storage Containers: The rugged surface helps hide wear and tear and provides a grip.

Technical Comparison

| Parameter | Stucco Aluminum | Plain Aluminum | Fiber Cement |

|---|---|---|---|

| Weight | 3-5 kg/m² | 2.7-8.1 kg/m² | 10-15 kg/m² |

| Installation | Mechanical fixing | Welding/fixing | Special fasteners |

| Maintenance | Wipe clean | Periodic cleaning | Repainting needed |

| Cost | $$ | $-$$ | $$$ |

Frequently Asked Questions

| Question | Professional Answer |

|---|---|

| How thick is standard stucco aluminum? | Most common: 1.2-3.0mm for architectural use |

| Can it be painted? | Pre-coated available, but raw sheets accept paint well |

| Is cutting difficult? | Requires carbide tools for clean edges |

| Minimum bending radius? | 3× thickness for 3003 alloy |

| Lead time for orders? | 2-3 weeks for standard sizes |

Quality Checklist

Verify alloy grade matches environment

Confirm texture depth meets design specs

Check for ISO 9001 certification

Request material test reports

Inspect packaging for transit protection

Why Choose Stucco Embossed Aluminum Sheet?

Choosing stucco embossed aluminum sheet means opting for a material that offers more than just basic performance. It provides an appealing visual texture, enhanced durability, and practical advantages like reduced glare and improved rigidity. Whether you’re designing a new refrigerator panel, insulating industrial pipes, or creating modern architectural features, this versatile aluminum sheet offers a reliable and aesthetically pleasing solution. Its combination of lightweight properties, corrosion resistance, and unique surface makes it a smart choice for many applications.

Conclusion

The stucco embossed aluminum sheet is a prime example of how a simple texture can significantly enhance the functionality and appearance of a material. From its unique stucco pattern to its diverse range of applications, this embossed aluminum product offers a valuable solution for industries seeking durability, aesthetics, and efficiency. Its continued popularity in fields ranging from refrigeration to construction highlights its versatility and enduring appeal as a superior aluminum sheet product.