What is a 1/4 Inch Aluminum Plate?

A 1/4 inch aluminum plate is a flat sheet of aluminum that measures 0.25 inches (6.35 mm) in thickness. This versatile material offers excellent strength-to-weight ratio, corrosion resistance, and durability for various industrial and commercial applications. Aluminum plates in this thickness are commonly used across multiple industries due to their optimal balance of strength and workability.

Key Properties and Advantages

| Property | Benefit | Application Impact |

|---|---|---|

| Lightweight | Easy handling and transport | Reduces overall project weight |

| Corrosion resistant | Long-lasting performance | Suitable for outdoor and marine use |

| High strength | Durable and reliable | Handles heavy loads and stress |

| Thermal conductivity | Efficient heat transfer | Ideal for heat exchange applications |

| Machinability | Easy to cut and shape | Simplifies fabrication process |

| Recyclable | Environmentally friendly | Sustainable material choice |

Common Specifications and Types

| Aluminum Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Typical Applications |

|---|---|---|---|

| 6061-T6 | 310 | 276 | Structural components, frames |

| 5052-H32 | 228 | 193 | Marine applications, panels |

| 3003-H14 | 200 | 186 | Chemical equipment, gutters |

| 7075-T6 | 572 | 503 | Aerospace, high-stress parts |

| 2024-T3 | 469 | 324 | Aircraft structures, fasteners |

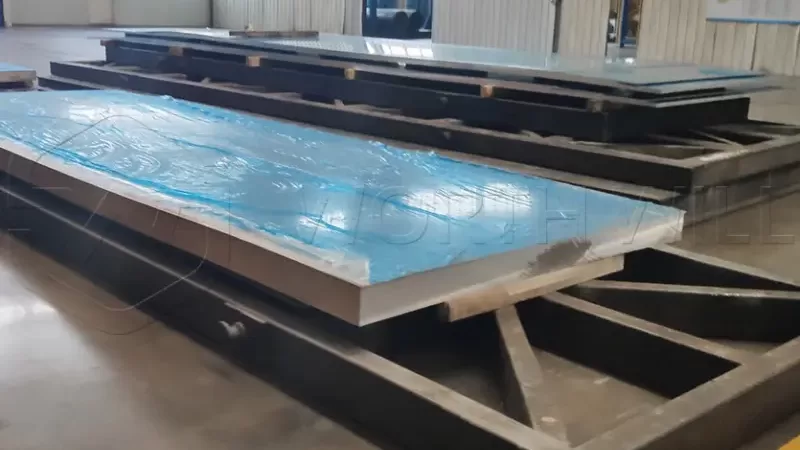

Manufacturing Process

The production of 1/4 inch aluminum plates involves several precise steps:

- Raw aluminum ingot melting and purification

- Continuous casting into large slabs

- Hot rolling to reduce thickness

- Cold rolling for final dimensions and surface finish

- Heat treatment (for tempered grades)

- Quality inspection and cutting to size

Applications and Industries

Construction and Architecture

- Building facades and curtain walls

- Structural supports and brackets

- Roofing and siding systems

- Decorative elements and trim

Aerospace and Aviation

- Aircraft structural components

- Interior paneling and flooring

- Wing and fuselage sections

- Equipment mounting plates

Marine Industry

- Boat hulls and superstructures

- Deck plates and walkways

- Marine hardware and fittings

- Docking equipment

Automotive Sector

- Truck beds and trailers

- Body panels and chassis components

- Heat shields and engine parts

- Custom automotive modifications

Industrial Equipment

- Machine frames and bases

- Conveyor system components

- Process equipment linings

- Work surfaces and tables

Installation and Fabrication Tips

Working with 1/4 inch aluminum plate requires proper techniques:

- Use appropriate cutting tools (carbide-tipped blades)

- Employ correct welding methods (MIG or TIG welding)

- Implement proper drilling techniques with lubrication

- Follow safety protocols for handling sharp edges

- Store plates flat to prevent warping

Maintenance and Care

Maintaining aluminum plates is relatively simple:

- Regular cleaning with mild detergent and water

- Periodic inspection for surface damage

- Prompt treatment of any corrosion spots

- Proper storage to avoid surface scratches

- Avoid contact with dissimilar metals to prevent galvanic corrosion

Cost Considerations

| Factor | Impact on Cost | Typical Range |

|---|---|---|

| Aluminum grade | Higher grades cost more | $3-8 per pound |

- Quantity ordered

- Custom cutting requirements

- Surface finish specifications

- Delivery timeline

- Market aluminum prices

Quality Standards and Certifications

Reputable manufacturers adhere to:

- ASTM B209 standards

- ISO 9001 quality management

- Military specifications (where applicable)

- Industry-specific certifications

- Third-party quality verification

Environmental Impact

Aluminum plates offer environmental benefits:

- 100% recyclable without quality loss

- Energy efficient production process

- Long service life reduces replacement needs

- Lightweight nature reduces transportation emissions

- Non-toxic and safe for various applications

Future Trends

The 1/4 inch aluminum plate market continues evolving:

- Development of stronger alloy compositions

- Improved surface treatment technologies

- Enhanced recycling processes

- Growth in renewable energy applications

- Expansion in automotive lightweighting

FAQ Section

What is the weight of a 1/4 inch aluminum plate?

A 1/4 inch aluminum plate weighs approximately 3.6 pounds per square foot, making it substantially lighter than steel while maintaining good structural integrity.

Can 1/4 inch aluminum plate be welded?

Yes, 1/4 inch aluminum plate can be welded using appropriate techniques. MIG and TIG welding are commonly used, with proper preparation and the right filler materials being essential for strong, clean welds.

How does 1/4 inch aluminum plate compare to steel?

While steel offers higher strength, aluminum provides better corrosion resistance, lighter weight, and easier machinability. The choice depends on specific application requirements and environmental conditions.

What surface finishes are available?

Common finishes include mill finish, brushed, polished, anodized, and painted surfaces. The choice depends on aesthetic requirements and environmental exposure conditions.

Is 1/4 inch aluminum plate suitable for outdoor use?

Yes, aluminum naturally forms a protective oxide layer that makes it highly resistant to atmospheric corrosion. For harsh marine environments, specific marine-grade alloys like 5052 or 5086 are recommended.

How should I cut 1/4 inch aluminum plate?

Use carbide-tipped blades for sawing, plasma cutting for complex shapes, or waterjet cutting for precision work. Always use appropriate safety equipment and proper cutting techniques.

Can aluminum plates be bent or formed?

Yes, 1/4 inch aluminum plate can be formed and bent using proper equipment. The bend radius depends on the specific alloy and temper, with softer tempers allowing tighter bends.