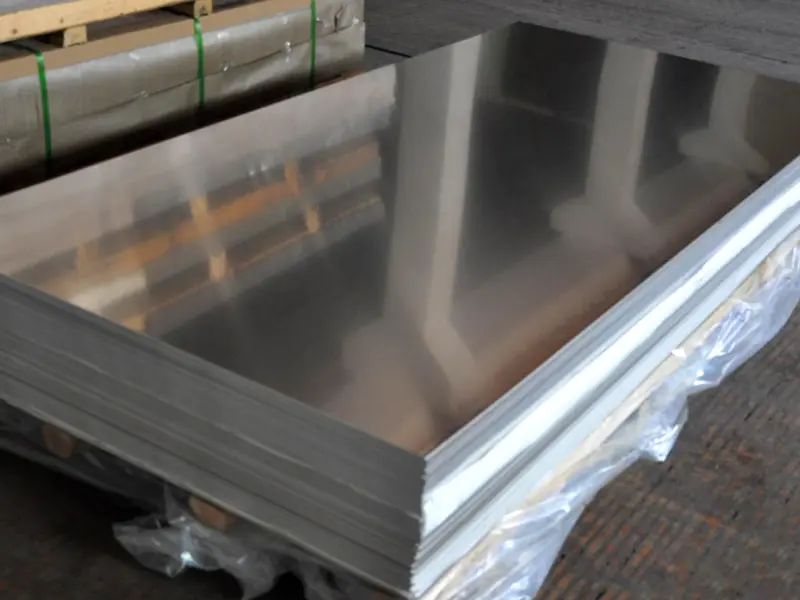

The 4×8 ft 1050 aluminum sheet is one of the most common aluminum products used in construction, industry, decoration, and daily life. This sheet is made from alloy 1050, known for its excellent corrosion resistance, high thermal conductivity, and good formability. Many buyers search for 1050 aluminum sheet 4×8 size because it provides standard dimensions, easy handling, and cost-effective performance.

Classification of 1050 Aluminum Sheets

| Type | Features | Typical Uses |

|---|---|---|

| Plain sheet | Smooth surface, easy to cut and bend | Roofing, wall panels, signage |

| Stucco embossed | Textured finish, anti-slip | Insulation, decorative panels |

| Anodized sheet | Corrosion-resistant surface | Exterior decoration, cladding |

| Color-coated sheet | Painted or coated with colors | Interior panels, advertising boards |

Standard Size: 4×8 ft (1220 x 2440 mm)

- Length: 2440 mm (8 ft)

- Width: 1220 mm (4 ft)

- Thickness range: 0.3 mm – 6 mm

- Weight depends on thickness and density

Why Choose the 4×8 ft Size for Aluminum Sheets?

The 4×8 ft (approximately 1219mm x 2438mm) dimension is a standard and highly practical size for aluminum sheets. This specific cut offers numerous advantages that contribute to its popularity:

- Standardization: The 4×8 ft size is globally recognized, ensuring compatibility and availability across different suppliers and machinery.

- Reduced Waste: For many common construction, fabrication, and manufacturing projects, a 4×8 ft sheet minimizes off-cuts, leading to cost savings and environmental benefits.

- Ease of Handling: While large enough for significant projects, a 4×8 ft 1050 aluminum sheet is still manageable for transport and positioning with standard equipment.

- Cost-Effectiveness: Purchasing in standard sizes often results in better pricing and availability compared to custom-cut sheets.

- Versatility: This size strikes a balance, providing enough material for larger components while being easily cut down for smaller parts.

When you specify a 4×8 ft 1050 aluminum sheet, you’re choosing a material that is not only high-performing but also practical and economical for a wide range of uses.

Key Features and Benefits of 4×8 ft 1050 Aluminum Sheet

The combination of the 1050 alloy’s properties and the convenient 4×8 ft size results in a material with a compelling set of features and benefits:

| Feature | Benefit |

|---|---|

| High Purity (99.5% Al) | Excellent corrosion resistance and superior conductivity. |

| Standard 4×8 ft Size | Minimizes waste, cost-effective, easy to handle and transport. |

| Excellent Formability | Can be easily bent, deep-drawn, and shaped for complex designs. |

| High Conductivity | Ideal for electrical busbars, heat sinks, and thermal management systems. |

| Corrosion Resistant | Suitable for outdoor, marine, and chemical environments. |

| Good Weldability | Compatible with various welding methods, allowing for strong joins. |

| Lightweight | Reduces overall project weight, improving efficiency and handling. |

| Non-Magnetic | Applicable in sensitive electronic and laboratory settings. |

| Aesthetic Finish | Bright, reflective surface, suitable for decorative and signage uses. |

These attributes make the 4×8 ft 1050 aluminum sheet a highly adaptable material for diverse industrial and commercial applications.

Common Applications of 4×8 ft 1050 Aluminum Sheet

The versatility of the 4×8 ft 1050 aluminum sheet means it finds its way into an incredible array of products and industries. Its specific properties make it invaluable for tasks requiring both performance and durability.

Here are some of the most common applications where you’ll find the 4×8 ft 1050 aluminum sheet being utilized:

- Building and Construction:

- Roofing, cladding, and wall panels.

- Decorative architectural elements.

- Ducting and ventilation systems.

- Electrical and Electronics:

- Busbars and electrical conductors due to high conductivity.

- Capacitor foils and electrical enclosures.

- Heat sinks for cooling electronic components.

- Chemical and Food Processing:

- Storage tanks and containers for various liquids and powders.

- Piping and heat exchanger components.

- Food-grade processing equipment surfaces.

- Signage and Advertising:

- Road signs, traffic signs, and directional signs.

- Display panels and billboards.

- Decorative and reflective panels.

- General Fabrication and Manufacturing:

- Toolboxes, custom enclosures, and machine parts.

- Automotive interior panels and non-structural components.

- Marine components where corrosion resistance is crucial.

- Lighting and Reflectors:

- Reflective surfaces for light fixtures and industrial lighting.

- Decorative lighting elements.

- Cookware:

- Bases for non-stick pans due to excellent thermal conductivity.

No matter the requirement, from a robust outdoor sign to a precise electrical component, the 4×8 ft 1050 aluminum sheet often provides the perfect solution.

Specifications of 1050 Aluminum Sheet

Understanding the detailed specifications of 1050 aluminum sheet is crucial for ensuring it meets your project’s precise requirements. These specifications outline its chemical makeup and mechanical performance.

1. Chemical Composition (Weight %)

The high purity of 1050 aluminum is evident in its chemical composition.

| Element | Minimum (%) | Maximum (%) |

|---|---|---|

| Aluminum (Al) | 99.50 | – |

| Silicon (Si) | – | 0.25 |

| Iron (Fe) | – | 0.40 |

| Copper (Cu) | – | 0.05 |

| Manganese (Mn) | – | 0.05 |

| Magnesium (Mg) | – | 0.05 |

| Zinc (Zn) | – | 0.05 |

| Titanium (Ti) | – | 0.03 |

| Other (each) | – | 0.03 |

| Other (total) | – | 0.10 |

Note: These values are typical and may vary slightly based on specific manufacturing standards (e.g., ASTM, EN).

2. Mechanical Properties (Typical, for various tempers)

The mechanical strength of 1050 aluminum sheet depends largely on its temper, which indicates the amount of cold working it has undergone.

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) (50mm gauge) |

|---|---|---|---|

| O | 60-95 | 20-55 | 20-35 |

| H12 | 80-110 | 70-95 | 10-20 |

| H14 | 90-120 | 80-105 | 7-15 |

| H18 | 120-150 | 110-140 | 3-8 |

- Temper ‘O’: Fully annealed (softest, most ductile).

- Temper ‘H1X’: Strain hardened, non-heat-treatable. H12 (1/4 hard), H14 (1/2 hard), H18 (full hard) indicate increasing strength and decreasing ductility.

3. Physical Properties (Typical Values)

| Property | Value | Unit |

|---|---|---|

| Density | 2.71 | g/cm³ |

| Melting Point | 640-655 | °C |

| Electrical Conductivity | 59-61 | % IACS (International Annealed Copper Standard) |

| Thermal Conductivity | 220 | W/m·K |

| Modulus of Elasticity | 69-70 | GPa |

4. Standard Thickness Options for 4×8 ft 1050 Aluminum Sheet

4×8 ft 1050 aluminum sheet is available in a wide range of thicknesses to suit diverse application needs. These options allow for precision in design and engineering.

| Thickness (mm) | Thickness (inches, approx.) | Common Applications |

|---|---|---|

| 0.5mm | 0.020″ | Foils, thin liners, decorative accents, light panels |

| 0.8mm | 0.031″ | Light fabrication, signage, protective coverings |

| 1.0mm | 0.039″ | Electrical components, general sheet metal work |

| 1.5mm | 0.059″ | HVAC ducting, moderate structural elements |

| 2.0mm | 0.079″ | Busbars, tanks, general fabrication |

| 3.0mm | 0.118″ | Medium-duty construction, strong enclosures |

| 4.0mm | 0.157″ | Industrial components, marine parts |

| 5.0mm | 0.197″ | Heavier structural parts, robust containers |

| 6.0mm | 0.236″ | Heavy-duty fabrication, load-bearing applications |

Other thicknesses may be available upon request.

Applications of 4×8 ft 1050 Aluminum Sheet

The 1050 aluminum sheet is widely used because of its purity and versatility. Main applications include:

- Construction and architecture

- Roofing and wall panels

- Ceilings and partitions

- Decorative cladding

- Industry and manufacturing

- Machine parts

- Storage tanks

- Packaging materials

- Commercial uses

- Advertising boards

- Shop decoration

- Display stands

- Household uses

- Kitchen utensils

- Appliances

- Furniture decoration

Reference Prices (per sheet 4×8 ft)

| Thickness (mm) | Weight (kg) | Price Range (USD) |

|---|---|---|

| 0.5 mm | ~4.5 kg | $25 – $35 |

| 1.0 mm | ~9.0 kg | $40 – $55 |

| 2.0 mm | ~18 kg | $75 – $95 |

| 3.0 mm | ~27 kg | $110 – $140 |

| 5.0 mm | ~45 kg | $180 – $220 |

Note: Prices depend on supplier, order volume, and market conditions.

Advantages of Choosing 4×8 ft 1050 Aluminum Sheet

- Standard size fits many applications

- Lightweight and easy to handle

- High corrosion resistance

- Excellent workability and weldability

- Cost-effective compared to other alloys

- 100% recyclable and eco-friendly

Processing and Fabrication Tips for 4×8 ft 1050 Aluminum Sheet

Working with a 4×8 ft 1050 aluminum sheet is generally straightforward due to its excellent workability. Here are some quick tips for processing:

- Cutting: Can be easily cut using shears, saws, or laser/plasma cutting. Ensure sharp tools to prevent burring.

- Bending and Forming: Its high ductility allows for tight bends. Consider the temper of the sheet; annealed (O temper) sheets will form more easily.

- Welding: 1050 aluminum is very weldable, commonly using TIG (GTAW) or MIG (GMAW) processes. Proper filler material (e.g., 1050, 1100, or 4043) should be selected.

- Surface Treatment: Can be polished, anodized, or painted for aesthetic appeal or enhanced corrosion resistance.

- Cleaning: Always clean the surface thoroughly before welding or applying coatings to ensure optimal results.

Why Choose Us for Your 4×8 ft 1050 Aluminum Sheet Needs?

When sourcing your 4×8 ft 1050 aluminum sheet, you need a reliable partner committed to quality and customer satisfaction. We pride ourselves on providing:

- High-Quality Materials: Our 1050 aluminum sheets meet stringent industry standards, ensuring purity and consistent performance.

- Extensive Inventory: We maintain a broad stock of 4×8 ft 1050 aluminum sheet in various thicknesses to meet immediate demands.

- Competitive Pricing: We offer value-driven pricing without compromising on material quality.

- Expert Support: Our knowledgeable team is ready to assist you with material selection and technical queries.

- Efficient Delivery: We understand the importance of timely delivery to keep your projects on schedule.

Partner with us for your next project requiring dependable and high-performance aluminum sheet metal.