Welcome to our in-depth guide on the 4×8 aluminum sheet, a highly sought-after and incredibly versatile material essential for numerous projects. When you need a durable, lightweight, and easy-to-work-with metal, the 4×8 aluminum sheet consistently delivers. This standard size, measuring 4 feet by 8 feet (or 32 square feet), is a prime choice for everything from robust construction applications to intricate creative endeavors.

Why Choose a 4×8 Aluminum Sheet?

The 4×8 aluminum sheet represents a foundational product in the metals industry. Its consistent dimensions are well-suited for standard fabrication equipment and efficient transportation. This makes the 4×8 aluminum sheet an accessible and adaptable material for both large-scale manufacturers and individual craftsmen, offering a robust yet lightweight metal panel solution.

Understanding 4×8 Aluminum Sheet Classifications

To select the ideal 4×8 aluminum sheet for your task, it’s vital to understand its various classifications. Aluminum sheets are typically categorized by their alloy, temper (or hardness), and surface finish. Each aspect significantly influences the sheet’s performance and suitability.

Alloy Types

Different aluminum alloys provide distinct properties, from enhanced strength to superior corrosion resistance. We will explore common alloys in a dedicated section below.

Temper Types

Temper refers to the material’s hardness, achieved through specific processing. Understanding temper is key for bending, forming, and structural applications.

| Temper Code | Description | Key Characteristic |

|---|---|---|

| -O | Annealed | Softest, most ductile, excellent for forming |

| -HXX | Strain Hardened (e.g., H14, H32, H34) | Strengthened by cold working, good workability |

| -TXX | Heat Treated (e.g., T4, T6) | Strengthened by heat treatment, very high strength |

Choosing the right temper for your 4×8 aluminum sheet ensures it will perform as expected during fabrication and in its final application.

Common Finishes

The surface finish of your 4×8 aluminum sheet can offer aesthetic appeal, enhanced protection, or improved functionality.

| Finish Type | Appearance & Properties | Common Use Cases for 4×8 Aluminum Sheet |

|---|---|---|

| Mill Finish | As produced, natural, unpolished look | General fabrication, non-visible parts |

| Brushed Finish | Matte, directional texture | Decorative panels, architectural details |

| Anodized Finish | Enhanced corrosion, wear resistance, color options | Architectural, marine, decorative |

| Painted/Coated | Specific color, added protection | Siding, signage, custom projects |

| Tread Plate | Raised diamond pattern for traction and durability | Flooring, ramps, truck beds, toolboxes |

Thickness Options for Your 4×8 Aluminum Sheet

The thickness of your 4×8 aluminum sheet is a critical specification that directly impacts its strength, weight, and suitability for various applications. We stock a comprehensive range of thicknesses to perfectly match your project’s needs.

Here’s a breakdown of common thicknesses for a 4×8 aluminum sheet and their typical applications:

| Thickness (Inches) | Thickness (mm) | Gauge (Approx.) | Typical Applications for 4×8 Aluminum Sheet |

|---|---|---|---|

| 0.020″ | 0.508mm | 24 Gauge | Very light panels, trim, crafts, HVAC ductwork |

| 0.032″ | 0.813mm | 20 Gauge | Light signs, HVAC, small enclosures, kick plates |

| 0.040″ | 1.016mm | 18 Gauge | General signs, flashings, light fabrication |

| 0.063″ | 1.600mm | 14 Gauge | Vehicle panels, general purpose fabrication, electrical boxes |

| 0.080″ | 2.032mm | 12 Gauge | Structural panels, trailer skins, medium-duty cabinetry |

| 0.090″ | 2.286mm | 11 Gauge | Machine guards, medium-duty flooring, industrial |

| 0.125″ (1/8″) | 3.175mm | 10 Gauge | Heavy-duty flooring, structural components, marine, toolboxes |

| 0.188″ (3/16″) | 4.775mm | 7 Gauge | Truck beds, heavy machinery parts, ramps, strong bases |

| 0.250″ (1/4″) | 6.350mm | 3 Gauge | Very heavy-duty structural work, jigs, base plates |

Selecting the appropriate thickness for your 4×8 aluminum sheet is key to achieving optimal performance and cost-efficiency. Thinner sheets offer flexibility and lightness, while thicker sheets provide superior rigidity and strength.

Popular Alloys for Your 4×8 Aluminum Sheet

The specific alloy determines the fundamental characteristics of an aluminum sheet. Below are some of the most commonly available aluminum alloys in the 4×8 sheet format, outlining their primary properties and typical uses:

| Alloy | Key Properties | Typical Applications for 4×8 Aluminum Sheet |

|---|---|---|

| 1100 | Purest aluminum, excellent formability, high corrosion resistance, non-heat treatable. | Decorative trim, chemical equipment, fin stock, nameplates, food processing. |

| 3003 | Good strength, excellent workability, good weldability, very good corrosion resistance. | Tanks, general fabrication, heat exchangers, lighting, HVAC ductwork, building products. |

| 5052 | Excellent corrosion resistance (especially in saltwater), high strength-to-weight ratio, good formability. | Marine applications (boat hulls, fuel tanks), electronic chassis, pressure vessels, general sheet metal work. |

| 6061 | High strength, good weldability, good machinability, heat-treatable for even greater strength. | Structural components, frames, machine parts, recreational products, aerospace components. |

| 7075 | Very high strength, comparable to many steels, heat-treatable. | Aircraft structures, high-stress parts, tooling, gears (less common for general 4×8 sheets, but available for specific uses). |

Choosing the correct alloy for your 4×8 aluminum sheet is critical for ensuring long-term success and optimal material performance in its intended environment.

Diverse Applications of 4×8 Aluminum Sheets

The remarkable versatility of the 4×8 aluminum sheet makes it an indispensable material across a multitude of industries. This standard size excels in numerous applications:

- Construction & Architecture: Roofing, siding, decorative panels, fascias, column covers, interior finishes.

- Transportation: Vehicle panels (trucks, trailers, buses), marine vessels (boat hulls, decks), railcar components, RV siding.

- Signage & Displays: Backing for large signs, decorative display panels, custom signs, billboards.

- Manufacturing & Industrial: Machinery parts, equipment enclosures, storage tanks, conveyors, jigs, fixtures.

- HVAC Systems: Ductwork, air conditioning units, ventilation components.

- Consumer Products: Appliance parts, furniture components, outdoor equipment, protective covers.

- Art & Craft Projects: Sculptures, decorative pieces, custom metalwork, prototypes.

- Automotive: Performance parts, chassis components, interior panels, body repairs.

- Food Service: Countertops, splashbacks, equipment housing due to aluminum’s hygienic properties.

From heavy-duty industrial requirements to precise artistic creations, the 4×8 aluminum sheet provides a reliable and adaptable material solution.

Ensuring Safe Delivery: Packaging Your 4×8 Aluminum Sheet

We recognize the importance of your 4×8 aluminum sheet arriving in pristine condition. Our robust packaging procedures are meticulously designed to protect your material throughout transit.

| Packaging Element | Purpose |

|---|---|

| Protective Film | Prevents scratches and abrasions on the surface |

| Wooden Skids/Pallets | Provides sturdy base, prevents bending, aids handling |

| Steel/Plastic Banding | Secures the sheet stack, prevents shifting |

| Edge Protectors | Guards sheet edges against impact damage |

| Weather-Resistant Wrap | Protects against moisture and environmental factors (optional for long transit) |

Our commitment is to ensure your 4×8 aluminum sheet is delivered safely and ready for immediate use in your project, free from shipping damage.

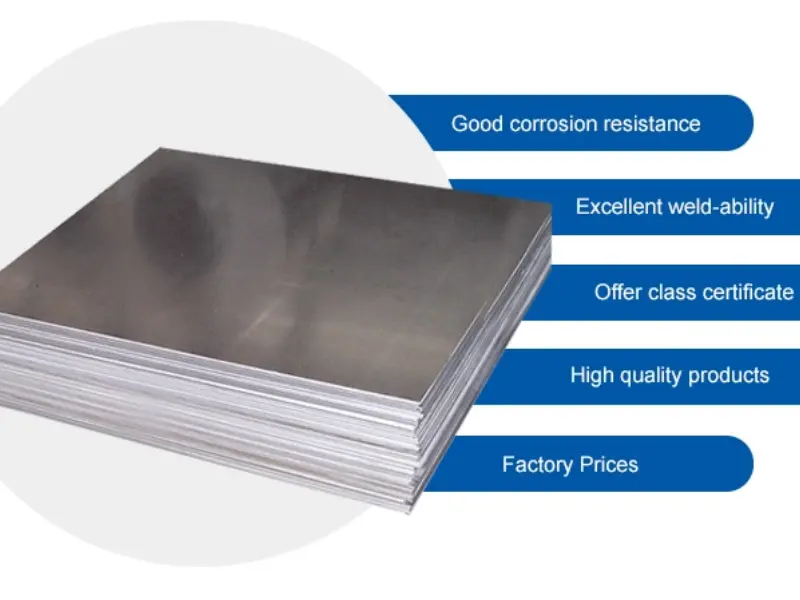

Key Benefits of Aluminum Sheets

Why is aluminum, especially in the convenient 4×8 sheet format, a material of choice for so many diverse applications? The advantages are compelling:

- Lightweight: Significantly lighter than steel, crucial for reducing overall weight in transportation and other applications.

- Corrosion Resistant: Naturally forms a protective oxide layer, offering excellent resistance to rust and corrosion, especially vital in harsh environments.

- Durable: Despite its light weight, aluminum sheets are strong and can withstand considerable stress and impact, ensuring a long service life.

- Recyclable: Aluminum is 100% recyclable without loss of quality, making it an environmentally responsible and sustainable choice.

- Easy to Fabricate: Aluminum sheets are relatively simple to cut, drill, weld, and form, enabling efficient manufacturing and complex designs.

- Aesthetic Appeal: Offers a modern, clean look that can be enhanced with various finishes, suitable for both functional and decorative uses.

These collective benefits firmly establish the 4×8 aluminum sheet as an outstanding material for a vast array of projects.

How to Select the Right 4×8 Aluminum Sheet

Choosing the perfect 4×8 aluminum sheet involves carefully evaluating several factors related to your project’s specific demands.

| Selection Factor | Key Considerations |

|---|---|

| Application | What will the sheet be used for? (e.g., structural, decorative, marine) |

| Environmental Exposure | Will it face moisture, chemicals, or extreme temperatures? (Impacts alloy choice) |

| Strength Needs | How much load or impact must the sheet withstand? (Determines alloy and thickness) |

| Formability | Will the sheet be bent or shaped? (Influences temper and alloy) |

| Desired Finish | Is a specific aesthetic or surface protection required? |

| Budget | Different alloys and thicknesses have varying costs. |

By thoughtfully considering these points, you can confidently select the ideal 4×8 aluminum sheet that perfectly aligns with your project’s requirements.

Customization Services for Your 4×8 Aluminum Sheet

While the 4×8 aluminum sheet is a standard size, we understand that many projects require precise modifications. We offer a range of customization services to ensure you get exactly what you need for your aluminum sheet purchases:

- Custom Cutting: Your 4×8 aluminum sheet can be precisely cut to smaller, exact dimensions.

- Drilling & Punching: For specific hole patterns or shapes required for assembly.

- Specialized Finishes: Beyond standard options, inquire about custom brushed, anodized, or painted finishes.

These services help streamline your fabrication process by providing material that is ready for immediate use.

FAQ

Q: Can 4×8 sheets be cut to smaller sizes?

A: Yes, most suppliers offer custom cutting services

Q: How many sheets fit on a truck?

A: Approximately 40-50 sheets per truckload

Q: What’s the weight of a standard sheet?

A: 13.6 to 108.8 lbs depending on thickness

Q: Can aluminum sheets be recycled?

A: Yes, 100% recyclable without quality loss

Q: How to prevent corrosion?

A: Choose appropriate alloy and maintain protective coating

Get Your Premium 4×8 Aluminum Sheet Today!

Whether your project is in construction, automotive, marine, or artistic design, a 4×8 aluminum sheet offers the ideal blend of durability, adaptability, and performance. We are dedicated to supplying high-quality aluminum sheet products at competitive prices, supported by exceptional customer service.

Do not compromise on quality or selection. Explore our extensive inventory of 4×8 aluminum sheets available in diverse alloys and thicknesses. Contact us today to discuss your project specifics or to request a personalized quote. Our expert team is ready to assist you in finding the perfect aluminum sheet solution for your unique requirements.