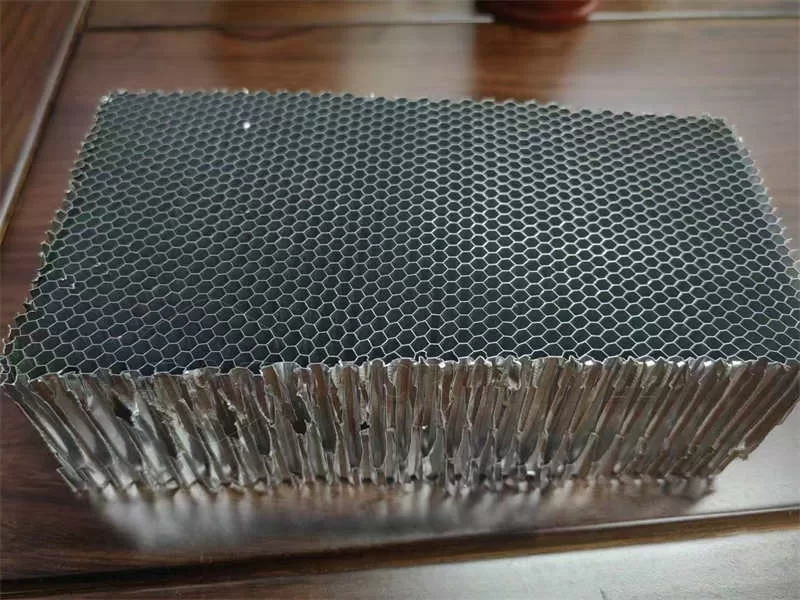

Aluminum honeycomb panels have wide applications in construction, transportation, and furniture because of their lightweight structure and strong mechanical properties. One of the most important factors to consider when choosing these panels is density. Density affects weight, strength, insulation, and overall performance.

Classification

Aluminum honeycomb panels can be classified based on core density, thickness, and surface coating. Each type offers different strength and weight advantages.

| Classification Type | Description |

|---|---|

| Low Density (20–30 kg/m³) | Lightweight, used for ceilings and partitions |

| Medium Density (40–60 kg/m³) | Balanced weight and strength, ideal for walls and furniture |

| High Density (70–120 kg/m³) | High strength, used in flooring, ships, and aerospace |

Thickness

The thickness of the panel and the core both play an important role in performance.

| Panel Thickness | Core Thickness | Application |

|---|---|---|

| 6–10 mm | 4–8 mm | Ceilings, partitions |

| 12–20 mm | 8–15 mm | Furniture, cladding |

| 25–50 mm | 15–30 mm | Floors, transport, industrial use |

Classification by Density Grades

| Density Category | Weight Range (kg/m³) | Core Cell Size | Primary Applications |

|---|---|---|---|

| Ultra-Light | 30-60 | 3/16″ – 1/4″ | Aerospace interiors |

| Light | 60-90 | 1/8″ – 3/16″ | Architectural cladding |

| Standard | 90-120 | 1/8″ – 1/4″ | Partition walls |

| High-Density | 120-180 | 1/16″ – 1/8″ | Flooring, heavy transport |

Thickness and Density Relationship

| Panel Thickness (mm) | Typical Density Range (kg/m³) | Face Sheet Thickness (mm) |

|---|---|---|

| 10 | 45-75 | 0.4-0.8 |

| 15 | 50-85 | 0.5-1.0 |

| 20 | 55-95 | 0.6-1.2 |

| 30 | 65-110 | 0.8-1.5 |

| 50 | 80-140 | 1.0-2.0 |

Aluminum Alloy Specifications

| Alloy Series | Density Impact | Honeycomb Core Use | Face Sheet Application |

|---|---|---|---|

| 3003 | Standard | Most common core | Interior panels |

| 5052 | +5% density | Marine environments | Exterior cladding |

| 6061 | +8% density | Structural applications | Heavy-duty surfaces |

| 7075 | +12% density | Aerospace | High-stress components |

Packaging Considerations by Density

| Density Grade | Packaging Method | Special Requirements |

|---|---|---|

| Low (30-60 kg/m³) | Vertical racks, soft wrapping | Fragile – extra corner protection |

| Medium (60-120) | Flat stacking, interleaving | Moisture barrier recommended |

| High (120-180) | Wooden crates, steel banding | Bottom support reinforcement |

Technical Properties vs. Density

| Density (kg/m³) | Compressive Strength (MPa) | Shear Strength (MPa) | Thermal Conductivity (W/mK) |

|---|---|---|---|

| 40 | 1.2-2.0 | 0.8-1.2 | 0.8-1.2 |

| 60 | 2.5-4.0 | 1.5-2.2 | 1.0-1.5 |

| 80 | 4.5-7.0 | 2.5-3.5 | 1.2-1.8 |

| 100 | 7 |

Why Density Matters in Honeycomb Panels

- Lightweight – lower density panels reduce weight in buildings and vehicles.

- Strength – higher density panels offer better compression and bending resistance.

- Thermal insulation – density influences heat and sound insulation properties.

- Cost efficiency – choosing the right density saves material and project costs.

Alloy Used in Aluminum Honeycomb Panels

Common alloys ensure durability and corrosion resistance.

| Alloy | Features | Use |

|---|---|---|

| 3003 | Excellent corrosion resistance, good strength | Architecture, furniture |

| 5052 | Higher strength, good welding ability | Transport, marine |

| 6061 | Very strong, heat treatable | Aerospace, industrial panels |

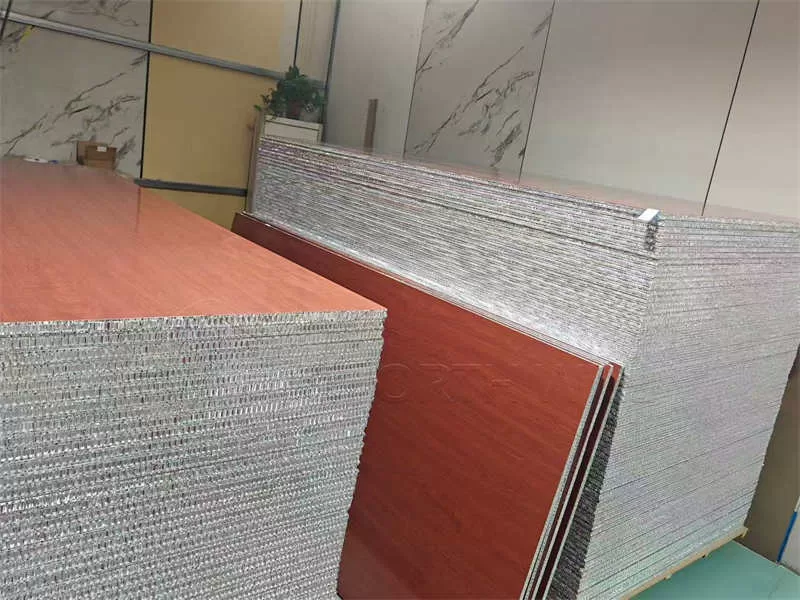

Packaging of Aluminum Honeycomb Panels

To protect panels during transportation, packaging is important.

- Panels are packed with protective film on the surface.

- Edges are covered with plastic or paper corner protectors.

- Panels are stacked on wooden pallets.

- Waterproof wrapping is used for export shipping.

Applications of Aluminum Honeycomb Panels

Aluminum honeycomb panels with different densities are wide applciations:

- Architecture: wall cladding, ceilings, partitions

- Furniture: lightweight tables, shelves, cabinets

- Transport: train doors, truck floors, ship walls

- Aerospace: aircraft flooring, panels, interior partitions

- Industry: machine enclosures, clean rooms

Technical Specification Table

| Property | Range / Value |

|---|---|

| Density | 20 – 120 kg/m³ |

| Panel Thickness | 6 – 50 mm |

| Core Thickness | 4 – 30 mm |

| Alloy | 3003 / 5052 / 6061 |

| Surface | PVDF, Polyester, Anodized |

| Weight | 2 – 8 kg/m² |

| Standard Size | 1220×2440 mm, custom sizes available |

Conclusion

Choosing the correct aluminum honeycomb panel density ensures the right balance of strength, weight, and performance for your project. Whether you need lightweight panels for furniture or high-density panels for industrial flooring, aluminum honeycomb panels are versatile and efficient.

WORTHWILL ALUMINUM provides customized aluminum honeycomb panels with different densities, thicknesses, and alloys to meet your needs.