When it comes to aluminum coils, especially the popular 3003 alloy, choosing the right type and supplier can make all the difference in your projects. Whether you’re in the construction, automotive, or packaging industry, understanding the unique properties and applications of different types of 3003 aluminum coils is essential. Let’s dive into the various types available and how to select the best manufacturer and supplier at a factory price.

What is 3003 Aluminum Coil?

Types of 3003 aluminum coil are an alloy that combines aluminum with manganese, offering excellent corrosion resistance, good formability, and moderate strength. Its versatility makes it one of the most widely used aluminum alloys in various industries. Common applications include roofing, siding, chemical equipment, and kitchenware.

Types of 3003 Aluminum Coil

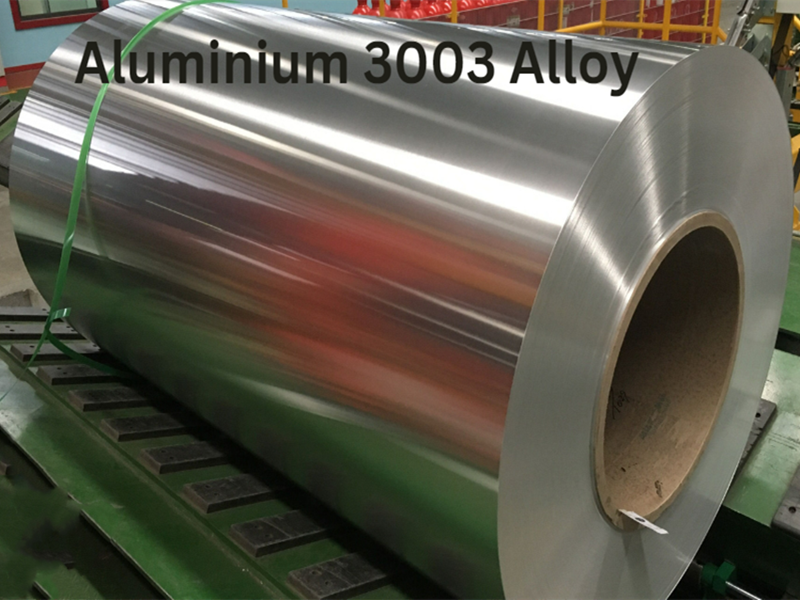

Plain 3003 Aluminum Coil:

- Description: This type of coil has a smooth, non-textured surface. It’s often used in applications where a polished finish is required, such as kitchenware and signage.

- Applications: Roofing, cladding, and general sheet metal work.

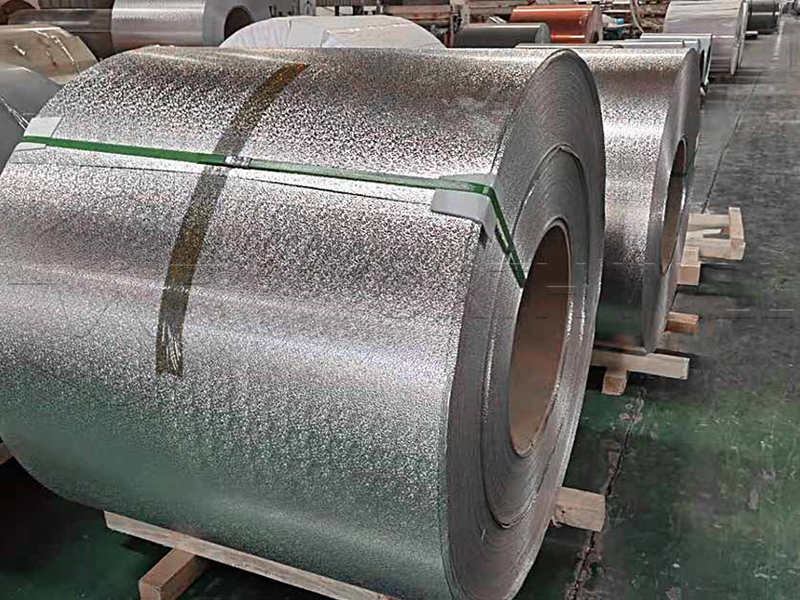

Embossed 3003 Aluminum Coil:

- Description: This coil features a textured surface, often in patterns like stucco or diamond. The embossed finish enhances durability and adds an aesthetic appeal.

- Applications: Refrigeration units, heat exchangers, and decorative applications.

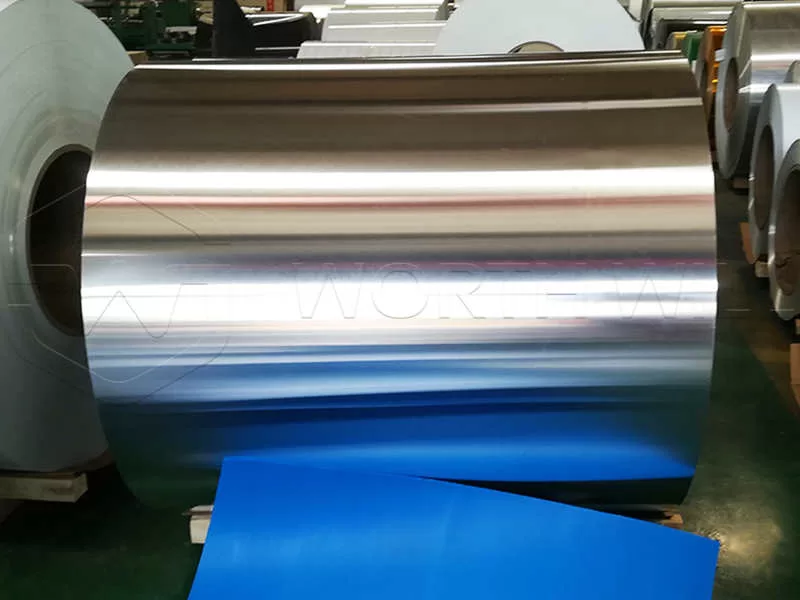

Anodized 3003 Aluminum Coil:

- Description: Anodizing adds a protective oxide layer to the aluminum, improving its corrosion resistance and appearance. This coil type is popular for architectural and decorative purposes.

- Applications: Building facades, window frames, and furniture.

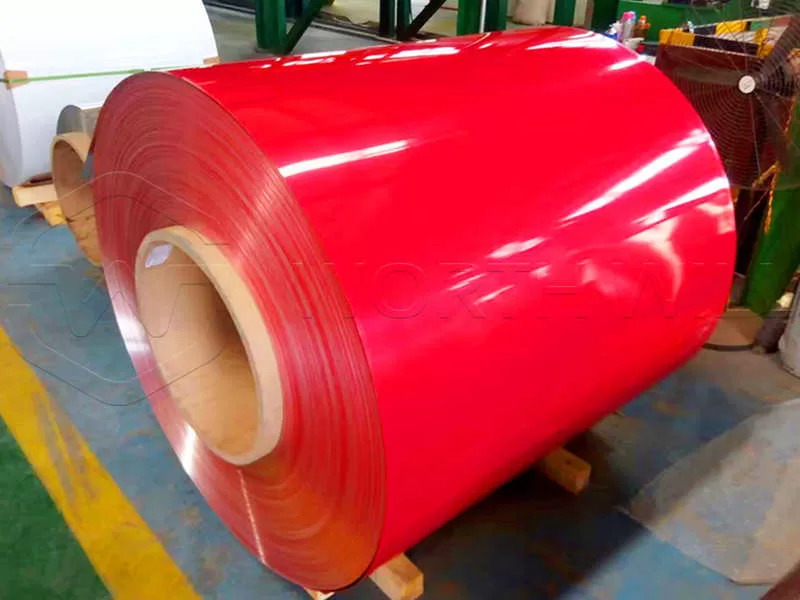

Coated 3003 Aluminum Coil:

- Description: Coated coils come with a layer of protective or decorative coating, such as PVDF or polyester. This adds color and additional protection against the elements.

- Applications: Exterior cladding, signage, and curtain walls.

Choosing the Right Manufacturer and Supplier

When selecting a 3003 aluminum coil manufacturer and supplier, several factors come into play:

- Quality Control: Ensure the manufacturer follows strict quality control measures. Look for certifications such as ISO 9001 that indicate adherence to international quality standards.

- Factory Price: Working directly with a factory or manufacturer often results in better pricing. Compare prices across different suppliers to ensure you’re getting competitive rates without compromising quality.

- Customization: Depending on your project, you might need coils in specific sizes, finishes, or coatings. A good manufacturer will offer customization options to meet your exact needs.

- Customer Service: Excellent customer service is crucial, from the initial inquiry to after-sales support. Choose a supplier that values communication and responsiveness.

- Experience and Reputation: Research the manufacturer’s history and reputation in the industry. An experienced supplier with positive reviews is more likely to deliver high-quality products consistently.

Conclusion

Choosing the right type of 3003 aluminum coil is crucial for the success of your project. Whether you need plain, embossed, anodized, or coated coils, selecting a reliable manufacturer and supplier at a factory price ensures that you receive high-quality materials tailored to your needs. Take the time to research and compare your options, and you’ll find the perfect partner for your aluminum coil needs.

By understanding the differences and knowing what to look for in a supplier, you can make informed decisions that lead to successful outcomes.