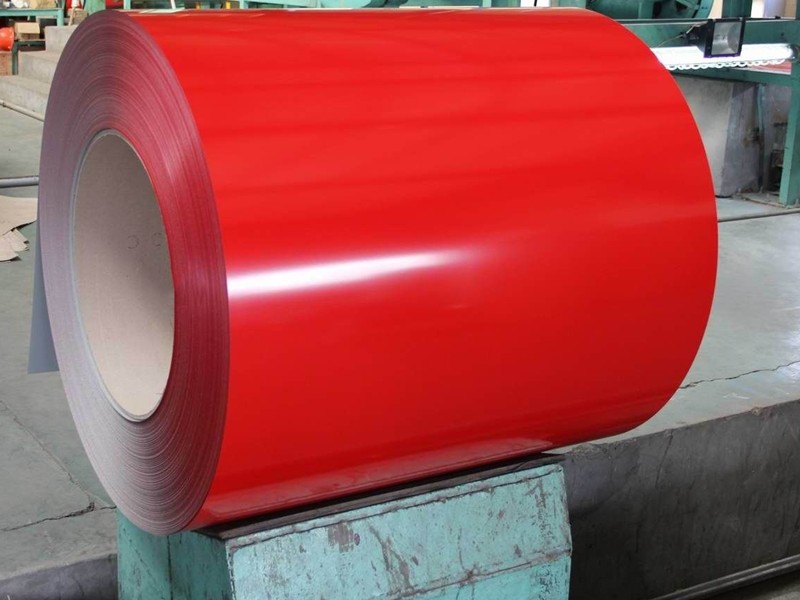

Pre Painted Aluminum Coil Introduction

Introduction

It’s a new type of metal decoration material that adopts high-quality aluminum alloy plate after roll forming and roll coating treatment on the surface. It has the characteristics of corrosion resistance, anti-ultraviolet radiation performance, good self-cleaning performance and hand feeling. Pre painted Color-coated aluminum coil introduction can be made into profile sheets of various colors and specifications for indoor and outdoor use.

Product Features

- Excellent anti-corrosion and anti-rust ability.

- Good wear resistance, long service life of more than 20 years.

- Excellent adhesion and flexibility, not easy to scratch and tear.

- Superior color stability.

- Ultra-long outdoor durability and weather resistance.

Application

Color-coated aluminum coils are suitable for decoration materials for interior and exterior walls, ceilings, column decorations, halls, etc. of buildings. It can be for use as a structural layer panel when used in a building curtain wall system.

Process Characteristics Of Color Coated Aluminum Coil

1. After processing the light aluminum coil, the surface of the aluminum coil is coating with various colors of paint, that’s the color-coated aluminum coil.

2. Colored aluminum is widely applciation in many fields such as insulation boards, aluminum curtain walls, aluminum-magnesium-manganese roofing systems, and aluminum ceilings. Because of its light texture, bright colors, easy processing, and no rust.

3. With divided into: surface-coated paints, polyester (PE) coated aluminum coils and fluorocarbon (PVDF) coated aluminum coils, rings.Due to different processing processes and purposes of use. Oxygen roller coated aluminum coils.

Of course, there are also situations where one side is with fluorocarbon and the other side is with polyester.

4. Coating thickness: The coating thickness can be into single coating (4μm-20 μm); double coating (25μm-28 μm); 3 coatings (35μm-38μm).

There are various patterns on the surface of color-coated aluminum coils. And they are also wood grain aluminum coils, stone grain aluminum coils, brick grain, camouflage aluminum coils, fabric aluminum coils, etc.

Because of different uses, it’s usually roofing material (aluminum-magnesium-manganese roofing system), ceiling material (for aluminum alloy ceiling), wire drawing board (the surface has been brushed), etc.