Painting Over Powder Coated Aluminium is widely used in architecture, furniture, windows, doors, and industrial products because of its durable and attractive finish. But sometimes, customers want to change the color, repair damaged coatings, or update the look.

Why Paint Over Powder Coated Aluminium?

Powder coating is strong, but it can fade or chip after years of exposure. Painting provides:

- A fresh and updated appearance

- Protection from corrosion and UV rays

- Color customization for branding or design

- Repair for scratches or damaged surfaces

Classification of Painting Methods

There are different methods when painting over powder coated aluminium:

| Method Type | Description | Difficulty | Durability |

|---|---|---|---|

| Light sanding + paint | Sanding the surface and applying liquid paint directly | Easy | Medium |

| Primer + topcoat | Using etch primer for adhesion before paint | Medium | High |

| Spray painting | Applying spray paint for smooth and even coating | Easy | Medium |

| Professional refinishing | Stripping the powder coat and applying new professional finish | Hard | Very High |

Thickness of Coating

When painting over powder coated aluminium, thickness is important:

| Coating Type | Thickness (µm) | Notes |

|---|---|---|

| Original powder coating | 60 – 120 | Already applied before painting |

| Liquid paint (single coat) | 25 – 40 | Suitable for quick finish |

| Primer + paint system | 50 – 80 | Provides better adhesion and durability |

| Professional refinish | 100 – 150 | Long-lasting protection and uniform surface |

Alloy Considerations

Not all aluminium alloys behave the same when painting. Common alloys include:

| Alloy | Characteristics | Painting Suitability |

|---|---|---|

| 1050 | Soft, good corrosion resistance | Easy to paint |

| 5052 | Strong, marine-grade, highly corrosion resistant | Excellent |

| 6061 | High strength, used in structures | Requires proper primer |

| 6063 | Popular for doors, windows, facade profiles | Very suitable |

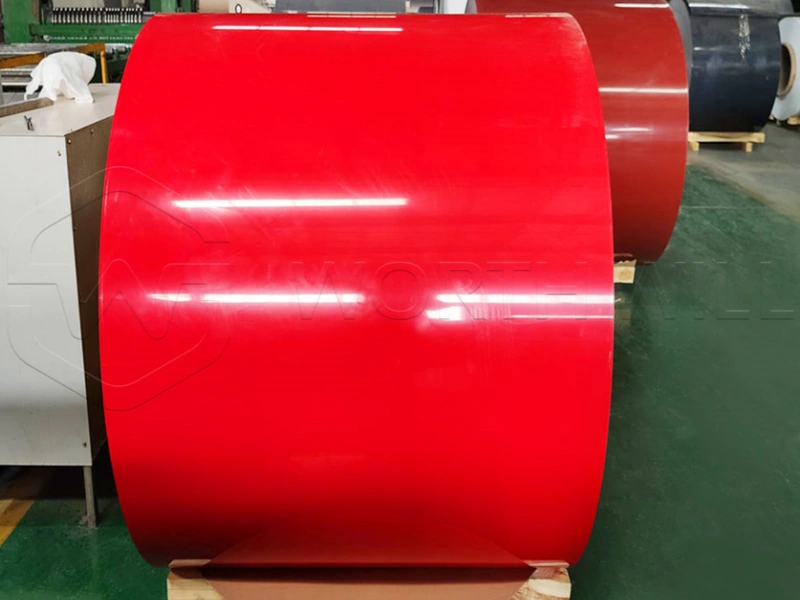

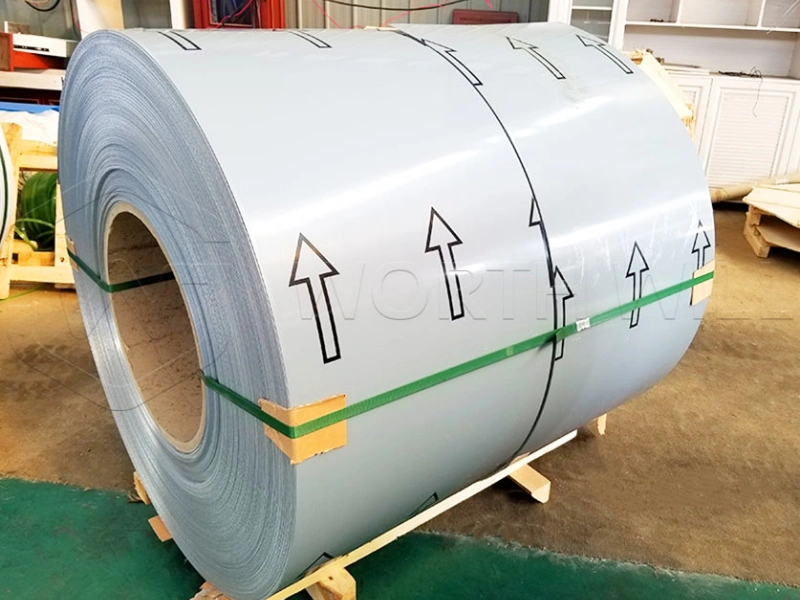

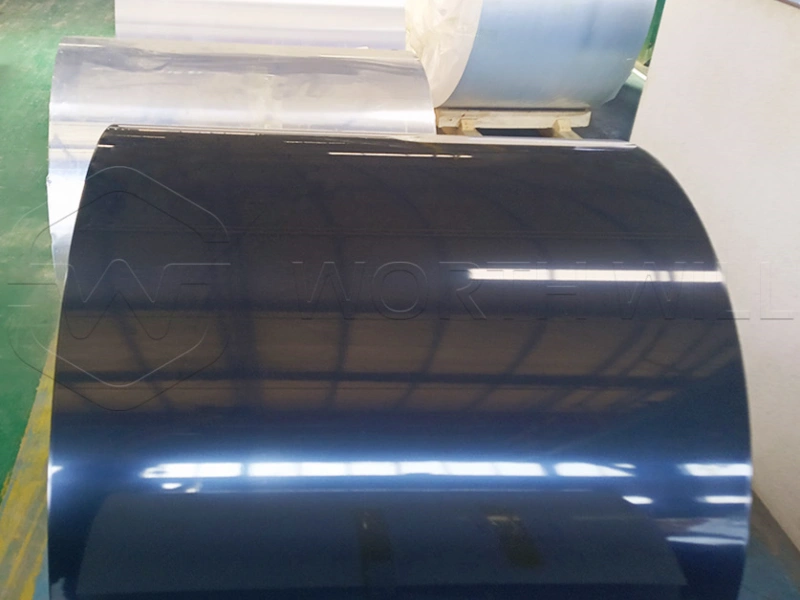

Packaging of Painted Aluminium

Once aluminium is painted, packaging is essential to avoid scratches:

- Protective film wrap to cover painted surfaces

- Foam layers between panels or profiles

- Carton box packaging for small items

- Wooden pallets for large sheets or panels

- Shrink wrap to protect from moisture during transport

Steps for Painting Over Powder Coated Aluminium

Step 1 – Cleaning the Surface

- Remove dirt, grease, or oil with mild detergent

- Rinse with clean water and dry

Step 2 – Sanding

- Lightly sand with 240–400 grit sandpaper

- Create a rough texture for better paint adhesion

Step 3 – Apply Primer

- Use etch primer or epoxy primer

- Improves bonding between aluminium and paint

Step 4 – Painting

- Apply paint evenly with a brush, roller, or spray

- Allow proper drying time between coats

Step 5 – Sealing (Optional)

- Apply clear coat for extra durability and gloss

Applications of Painted Aluminium

Painting over powder coated aluminium is common in:

- Architectural use: windows, doors, curtain walls

- Furniture: tables, chairs, cabinets

- Industrial equipment: machines, panels, enclosures

- Signage: advertising boards, displays

- Vehicles: trailers, trucks, and transportation units

Advantages and Disadvantages

| Advantage | Disadvantage |

|---|---|

| Gives a new look without full replacement | Requires surface preparation |

| Cost-effective compared to re-coating | Paint may peel if surface is not prepared well |

| Wide color options | Durability lower than original powder coat |

| Easy DIY or professional option | Multiple steps and drying time needed |

Frequently Asked Questions (FAQ)

Q1: Can I paint over powder coated aluminium directly?

A: Yes, but sanding and priming improve adhesion and durability.

Q2: What paint is best for aluminium?

A: Acrylic, epoxy, or polyurethane paints are recommended.

Q3: Do I need to remove the powder coating first?

A: Not always. Only remove it if it is severely damaged.

Q4: How long does painted aluminium last?

A: With proper preparation, painted aluminium can last 5–10 years outdoors.

Q: Can you paint directly over powder coated aluminium?

A: Yes, but only with proper surface preparation and compatible paint systems.

Q: How long does painted powder coat last?

A: 5-8 years with proper preparation and application, depending on environment.

Q: Do I need to remove all existing powder coat?

A: No, only remove if damaged or peeling. Sound coating can be painted over.

Q: What happens if you don’t prepare properly?

A: Adhesion failure, peeling, and premature coating degradation.

Q: Can I use household paint?

A: No, use only industrial-grade coatings designed for metal substrates.

Conclusion

Painting over powder coated aluminium is a practical solution for updating, repairing, or customizing surfaces. With the right preparation, choice of primer, and suitable paint, you can achieve long-lasting results. Whether for architectural panels, furniture, or industrial equipment, painted aluminium continues to provide both functionality and design flexibility.

Essential Steps for Painting Over Powder Coated Aluminium

Proper preparation is the most critical step for successful painting over powder coated aluminium. Skipping these steps can lead to poor adhesion and a finish that peels or chips easily. Take your time to ensure the surface is perfectly ready for paint.

Cleaning: How to Clean Powder Coated Aluminium

Before any sanding or priming, thoroughly clean the powder coated aluminium surface. Remove all dirt, grease, oil, and any loose paint flakes. Use a degreaser or a mild detergent mixed with water. For stubborn grime, a scrub brush can be helpful. Rinse the surface completely with clean water and allow it to dry fully. Any residue will prevent proper paint adhesion.

Sanding/Scuffing: Preparing the Surface for Adhesion

This is a crucial step for preparing powder coated aluminium for painting. The goal is not to remove the powder coating entirely, but to create a ‘tooth’ for the new paint to grip onto. Use fine-grit sandpaper, typically in the range of 220 to 320 grit. Lightly scuff the entire surface. For larger areas, an orbital sander can speed up the process. After sanding, wipe down the surface with a tack cloth to remove all dust. This ensures a smooth base for your primer.

Priming: The Right Primer for Powder Coated Surfaces

Applying a suitable primer is vital when painting over powder coated aluminium. A good primer acts as a bonding agent between the existing powder coat and your new paint. Look for primers specifically designed for non-ferrous metals, or those labeled as ‘etching primers’ or ‘epoxy primers’. These primers are formulated to adhere strongly to slick surfaces. Apply 1 to 2 thin coats of primer, allowing adequate drying time as per the manufacturer’s instructions between coats.