When it comes to creating stunning metal prints with sublimation, one of the most important decisions you’ll make is choosing the right finish for your aluminum sublimation sheets. The choice between matte finish and glossy finish isn’t just a minor detail; it significantly impacts the visual appeal, the way light interacts with your image, and the overall aesthetic of your finished piece.

Understanding Aluminum Sublimation Sheets

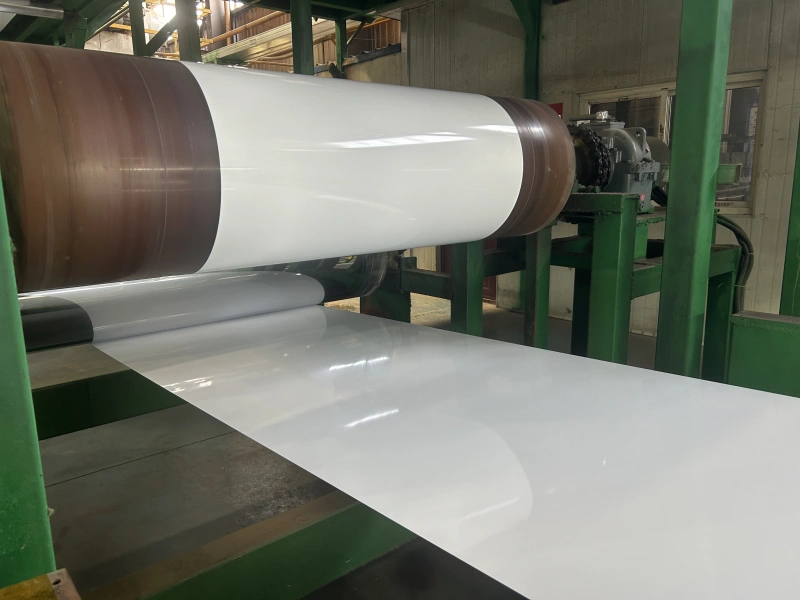

Before diving into the finishes, let’s quickly recap what an aluminum sublimation sheet is. These are specialized aluminum blanks coated with a polymer layer designed to absorb sublimation inks when heat and pressure are applied. The ink infuses into this coating, becoming a permanent part of the aluminum. This process creates exceptionally durable, scratch-resistant, and vibrant custom prints that are far more robust than traditional paper prints.

The final look, however, is heavily influenced by the type of coating used – specifically, whether it creates a matte or glossy surface.

The Allure of Glossy Aluminum Sublimation Sheets

A glossy finish is perhaps the most popular choice for aluminum sublimation sheets, renowned for its vibrant display and eye-catching sheen.

What is a Glossy Finish?

Glossy aluminum sublimation sheets feature a highly reflective, smooth surface that creates a mirror-like effect. This finish is designed to enhance color vibrancy and depth, making images “pop” with intense saturation and high contrast.

Pros of Glossy Finish:

- Vibrant Colors: Colors appear incredibly rich, deep, and vivid, making your images stand out with exceptional clarity.

- Enhanced Depth and Detail: The reflective surface creates a sense of depth, pulling viewers into the image. Fine details can often appear sharper due to the high contrast.

- High Contrast: Blacks are typically deeper, and whites are brighter, leading to a wider dynamic range in your prints.

- Eye-Catching Appeal: The shiny, reflective surface instantly grabs attention, making it ideal for impactful displays.

Cons of Glossy Finish:

- Glare and Reflections: The biggest drawback is its reflectivity. Light sources (windows, lamps) can cause significant glare, potentially obscuring parts of the image, especially in brightly lit rooms.

- Fingerprint Magnet: Glossy surfaces are prone to showing fingerprints, smudges, and dust, requiring more frequent cleaning.

- Less Suitable for Bright Environments: Due to glare, glossy prints can be difficult to view in direct sunlight or under strong artificial lighting.

Ideal Applications for Glossy Aluminum Sublimation Sheets:

- Professional Photography: Especially for vibrant landscapes, portraits with rich colors, and detailed macro shots.

- Art Reproductions: Bringing paintings and digital art to life with intense color and depth.

- High-Impact Signage: For indoor signs where you want to grab attention and showcase bold graphics.

- Awards and Recognition: Creating prestigious and visually stunning awards that shine.

- Promotional Items: Where a vibrant, “wow factor” is desired.

The Elegance of Matte Aluminum Sublimation Sheets

While glossy finishes shout for attention, matte finish aluminum sublimation sheets offer a more subdued, yet equally sophisticated, aesthetic.

What is a Matte Finish?

A matte finish is non-reflective, featuring a soft, muted surface that absorbs light rather than reflecting it. This creates a more subdued, elegant, and often sophisticated look, free from distracting glare.

Pros of Matte Finish:

- No Glare or Reflections: The primary advantage. Matte prints are easy to view from any angle and in any lighting condition, making them perfect for art galleries or rooms with multiple light sources.

- Reduced Fingerprints and Smudges: The non-glossy surface is far less prone to showing fingerprints and smudges, requiring less maintenance.

- Subtle Elegance: Offers a more understated and contemporary look, which can be preferred for certain artistic styles or minimalist decor.

- Detail Visibility (in certain contexts): While colors may be less vibrant, intricate details can sometimes be perceived more clearly because there are no reflections to interfere.

- Durable Feel: Many find that matte prints feel more robust and less delicate than their glossy counterparts.

Cons of Matte Finish:

- Less Vibrant Colors: Colors will appear softer and less saturated compared to glossy prints.

- Reduced Contrast: Blacks may not be as deep, and whites might not be as bright, leading to a slightly flatter image.

- Softer Appearance: While elegant, the image might lack the “pop” that a glossy finish provides.

Ideal Applications for Matte Aluminum Sublimation Sheets:

- Fine Art Photography: Particularly for black and white photos, vintage-style images, or those with a softer, painterly aesthetic.

- Gallery Displays: Where glare needs to be avoided to ensure every visitor can appreciate the artwork.

- Architectural or Interior Design Photos: Where a subtle, sophisticated presentation is preferred.

- Text-Heavy Designs: Signage or prints with a lot of text are often easier to read on a matte surface due to the lack of glare.

- High-Traffic Areas: Locations where prints might be frequently touched or exposed to varied lighting.

Factors to Consider When Choosing Your Finish

Deciding between matte vs. glossy aluminum sublimation sheets often comes down to a few key considerations:

- The Image Itself:

- Vibrant, colorful photos with high contrast: Usually shine on glossy aluminum sublimation sheets.

- Black and white photography, fine art with subtle tones, or muted color palettes: Often look exceptional on matte finish for a sophisticated feel.

- Designs with lots of text or intricate details: Might be more legible on matte due to reduced glare.

- The Display Environment:

- Bright rooms, near windows, or under direct spotlights: Matte finish is usually preferred to avoid glare.

- Areas with controlled lighting where reflections aren’t an issue (e.g., a dimly lit gallery spotlighting a single piece): Glossy finish can be stunning.

- High-traffic areas: Matte might be more practical to hide fingerprints.

- Desired Aesthetic:

- Modern, sleek, high-impact, dramatic: Lean towards glossy.

- Elegant, sophisticated, understated, classic, soft: Consider matte.

- Practicality and Maintenance:

- If you want a print that shows minimal fingerprints and is easy to maintain, matte is the clear winner.

- If you don’t mind occasional wiping to keep the surface pristine, and prioritize vibrancy, glossy is a great choice.

Matte vs. Glossy Aluminum Sublimation Sheets: Key Differences at a Glance

| Feature | Glossy Aluminum Sublimation Sheets | Matte Aluminum Sublimation Sheets |

|---|---|---|

| Reflectivity | High, mirror-like | Low, non-reflective |

| Color Vibrancy | Very high, rich, deep, intense | Softer, more muted, elegant |

| Contrast | High, vivid blacks and bright whites | Medium, natural, less “pop” |

| Glare/Reflections | Prone to glare from light sources | Virtually no glare, easy to view in varied lighting |

| Detail Perception | Can appear sharper due to contrast, but reflections can interfere | Clear, unobstructed view of details due to no glare |

| Fingerprints/Smudges | Easily shows fingerprints and smudges | Resists fingerprints and smudges more effectively |

| Overall Aesthetic | Modern, vibrant, impactful, “pop” | Elegant, sophisticated, subtle, soft, contemporary |

| Ideal Uses | Vibrant photos, high-impact signage, awards, areas with controlled lighting | Fine art, black & white photos, galleries, high-traffic areas, text-heavy designs |

Making Your Decision: Which Finish Works for You?

Ultimately, there’s no single “best” finish; it’s about what works best for your specific image, application, and environment.

- If your goal is to make colors explode and details leap off the print with a dazzling shine, a glossy aluminum sublimation sheet is likely your ideal choice. It’s perfect for eye-catching displays and images where maximum impact is desired.

- If you prioritize a sophisticated, glare-free viewing experience, particularly for subtle artwork, black and white photography, or designs in brightly lit spaces, then a matte aluminum sublimation sheet will serve you exceptionally well. It offers an understated elegance that can be truly captivating.

Consider your desired outcome carefully. Don’t be afraid to experiment with both finishes on smaller test pieces to see firsthand how your specific artwork translates. By making an informed decision, you’ll elevate your sublimation printing projects and create custom metal prints that perfectly match your vision.