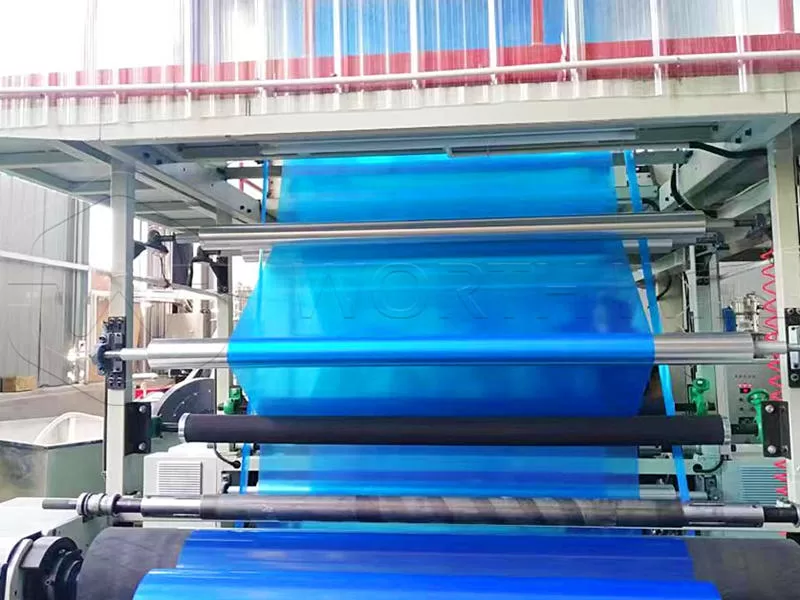

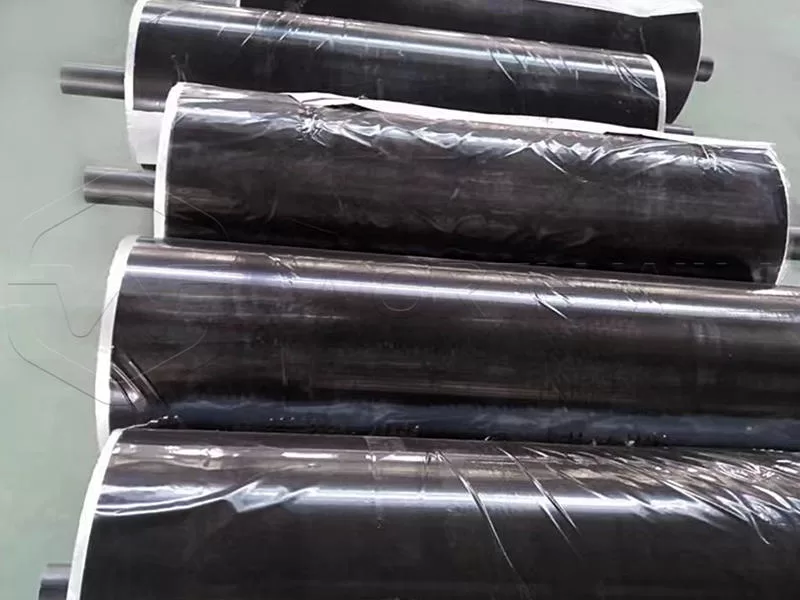

PE protective film is a thin, flexible layer of polyethylene used to protect surfaces from scratches, dust, and damage during manufacturing, shipping, or installation. Available in various colors like blue, black, white, and more, this film has wide uses across industries, including electronics, automotive, construction, and home appliances.

Why Use PE Protective Film?

- Surface Protection

PE protective film provides a barrier against scratches, dirt, and contaminants. This ensures that your products arrive in pristine condition, reducing the risk of damage during transport or handling. - Versatile Applications

PE films can be used on a variety of surfaces, including glass, metal, plastic, and painted surfaces. This versatility makes them suitable for many industries and applications. - Easy to Apply and Remove

The application process is straightforward, and the film can be easily removed without leaving residue behind. This means you can protect your surfaces during production or transport and remove the film just before use. - Customizable Options

PE protective films come in different colors and thicknesses, allowing you to choose the best option for your specific needs. Whether you need a highly visible film for easy identification or a clear film for unobtrusive protection, there’s a solution for everyone.

How to Get PE Protective Film

- Identify Your Requirements

Determine the specific needs of your project. Consider the surface you want to protect, the color of the film (such as blue, black, or white), and the required thickness. Understanding your needs will help you choose the right product. - Research Suppliers

Look for reputable suppliers or manufacturers that specialize in PE protective films. Check their websites, read reviews, and compare products to ensure they meet your quality standards. - Request Samples

Before making a bulk purchase, request samples from potential suppliers. This allows you to test the film’s adhesion, durability, and ease of removal on your specific surfaces. Evaluating samples ensures that the film meets your expectations. - Check Customization Options

If you have unique requirements, inquire about customization options. Many suppliers offer films in specific colors, lengths, or widths. This ensures that the film fits your project perfectly. - Bulk Orders and Pricing

Once you’ve selected a supplier and tested the film, discuss pricing for bulk orders. Many manufacturers offer discounts for larger quantities, making it cost-effective for businesses. - Place Your Order

After confirming all details, place your order. Ensure you have a clear understanding of shipping times and return policies, especially if you are ordering large quantities. - Application Instructions

When you receive your PE protective film, refer to the application instructions provided by the supplier. Proper application ensures maximum protection and ease of removal.

Benefits of Using PE Protective Film

- Cost-Effective Solution: Protecting your products with PE film can save money on potential damage or repairs.

- Improved Aesthetics: Using colored films can enhance the appearance of your products while keeping them safe.

- Reduced Cleaning Time: By preventing dirt and scratches, PE films reduce the time needed for cleaning and maintenance.

Conclusion

Getting PE protective film in various colors like blue, black, or white is a smart choice for protecting your products during transit or storage. With its versatility, easy application, and customizable options, PE film offers a reliable solution for many industries. By following the steps outlined above, you can ensure you select the right film for your needs and effectively safeguard your surfaces.

Key Products

- PE Protective Film

- Buy PE Protective Film

- Colored Protective Film

- Surface Protection Film

- PE Film for Manufacturing and Shipping