Difference Between Hot and Cold Rolling

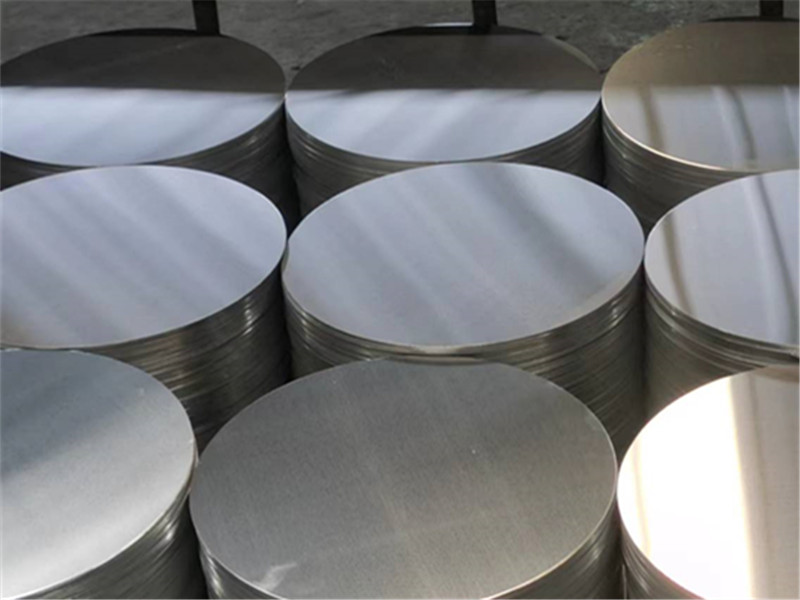

Hot rolling and cold rolling are the main production techniques of aluminum products. Both of them belong to metal process technique. Taking aluminum circle as an example. Due to the different production processes, there are hot rolling aluminum circle and cold rolling aluminum circle in the market.

What is Hold Rolling?

In terms of processing technology, hot rolling is hot working. Hot rolling refers to rolling above the crystallization temperature. The technique has unique features include low energy consumption, good plastic processing, low deformation resistance, insignificant work hardening, easy rolling, and reduced energy consumption required for metal deformation. Hot rolling is mainly used to produce steel structures, bridges, ships, vehicles and various mechanical parts.

What is Cold Rolling?

Cold rolling is relative to hot rolling. It’s cold working. And it refers to rolling below the crystallization temperature. Compared with hot rolling, cold rolling aluminum products have high strength. Therefore, cold rolling is very suitable for household appliances such as automobiles, refrigerators, washing machines, as well as industrial equipment and various building materials.

Hot Rolling vs Cold Rolling

- Price:The process of cold rolling aluminum circle is simple, and the price is cheaper than that of hot rolling aluminum circle.

- Different Properties:Hot rolling aluminum circle has good surface quality, strong mechanical properties and ductility, and good oxidation effect. Cold rolling aluminum circle has high strength.

- Different Uses:Cold rolling aluminum circles are mostly used in molds, and hot rolling aluminum sheets are suitable for stamping and stretching.

- Finished Product Difference:Usually the elongation of the cold rolled end product is lower than that of the hot rolled end product.

Our company produce hot rolling and cold rolling aluminum products. According to the needs of customers, our company provides aluminum products in various widths and thicknesses. More information, welcome to contact us.