In today’s world of personalized products and high-quality signage, aluminum sublimation metal sheet suppliers play a crucial role. These specialized sheets have revolutionized how images, designs, and artwork are brought to life with stunning clarity and incredible durability. If you’re looking to create vivid, long-lasting prints, understanding the world of aluminum sublimation sheets and finding the right supplier is key.

Why Choose Aluminum Sublimation Metal Sheets?

Choosing aluminum sublimation sheets for your printing projects offers a host of benefits that make them stand out.

Unmatched Durability and Longevity

One of the primary advantages is their exceptional durability. Once the image is sublimated, it becomes part of the aluminum’s coating. This makes the prints highly resistant to scratches, abrasions, moisture, and fading from UV light. They are perfect for both indoor and outdoor applications where longevity is a concern. Unlike traditional prints that can easily tear or degrade, metal prints offer a robust solution.

Vibrant and High-Quality Prints

Aluminum sublimation sheets produce prints with astonishing vibrancy and detail. The colors are incredibly rich, and the images boast a striking luminescence, especially on glossy finishes. The resolution and sharpness achieved are superior, making them ideal for photographic prints, fine art reproductions, and intricate graphics. The ability to capture such vivid details is a major reason many turn to aluminum sublimation metal sheet suppliers.

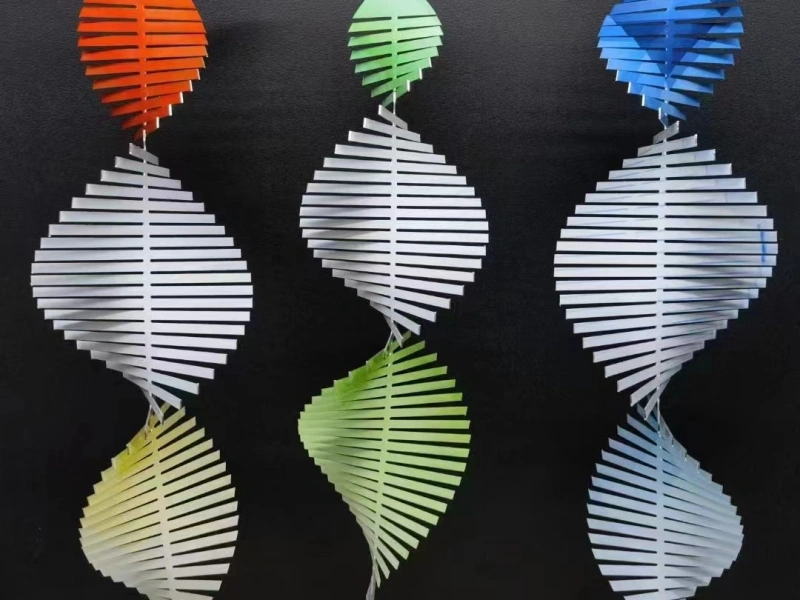

Versatility in Application

These sheets are incredibly versatile. They can be cut into various shapes and sizes, and different finishes offer unique aesthetic appeals. From sleek, modern looks to more artistic expressions, there’s a sublimation metal sheet for almost any creative vision. Their adaptability makes them suitable for a wide range of products.

Lightweight Yet Sturdy

Despite their impressive strength and durability, aluminum sheets are remarkably lightweight. This makes them easy to handle, transport, and hang, especially for larger pieces. Their lightweight nature also helps reduce shipping costs, which is a practical benefit for both suppliers and end-users.

Classification of Aluminum Sublimation Metal Sheets

When you search for aluminum sublimation metal sheet suppliers, you’ll encounter various classifications. Understanding these helps you choose the right product for your specific needs.

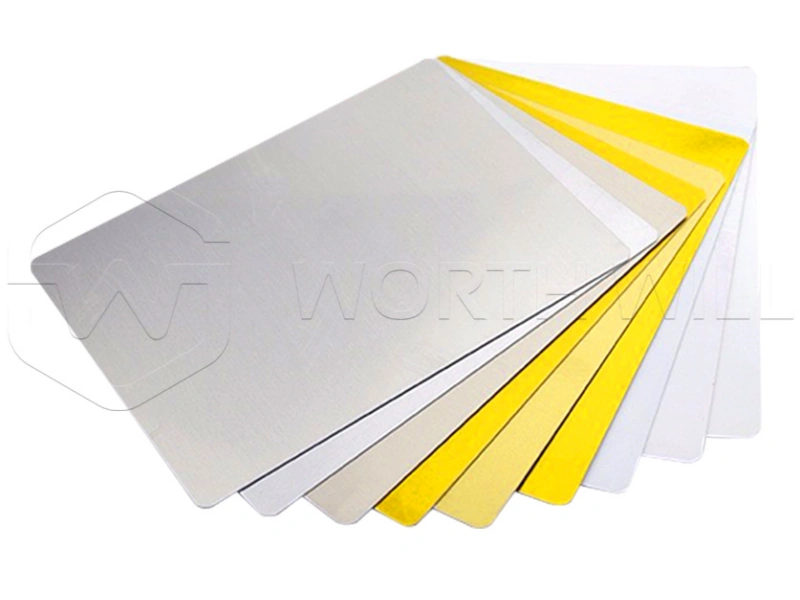

Thickness

Aluminum sublimation sheets come in a range of thicknesses, typically measured in millimeters or gauges.

- Thinner Sheets (e.g., 0.5mm – 0.75mm): These are often used for smaller decorative items, custom metal prints, photo panels, and internal signage. They are lighter and more flexible.

- Thicker Sheets (e.g., 1.0mm – 3.0mm): These provide greater rigidity and are preferred for larger signs, outdoor displays, architectural applications, and situations where structural integrity is important.

The choice of thickness depends on the intended use, desired rigidity, and overall aesthetic.

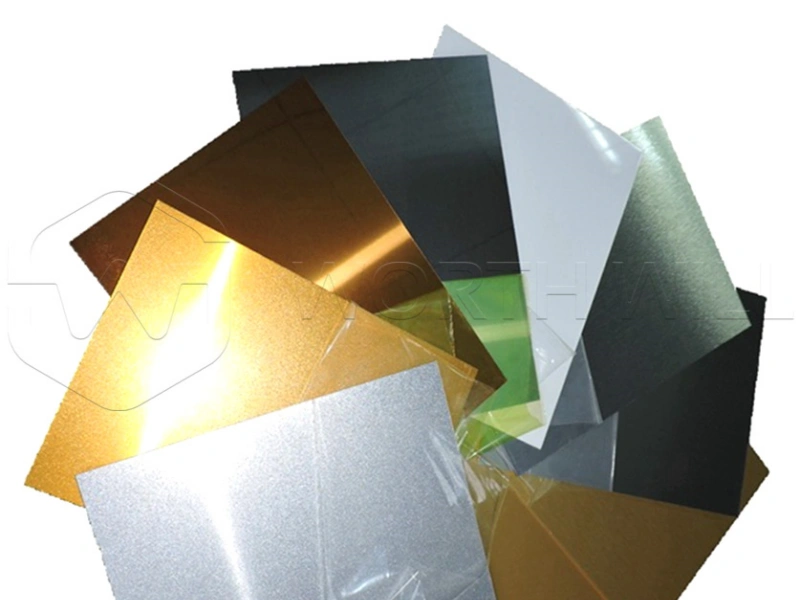

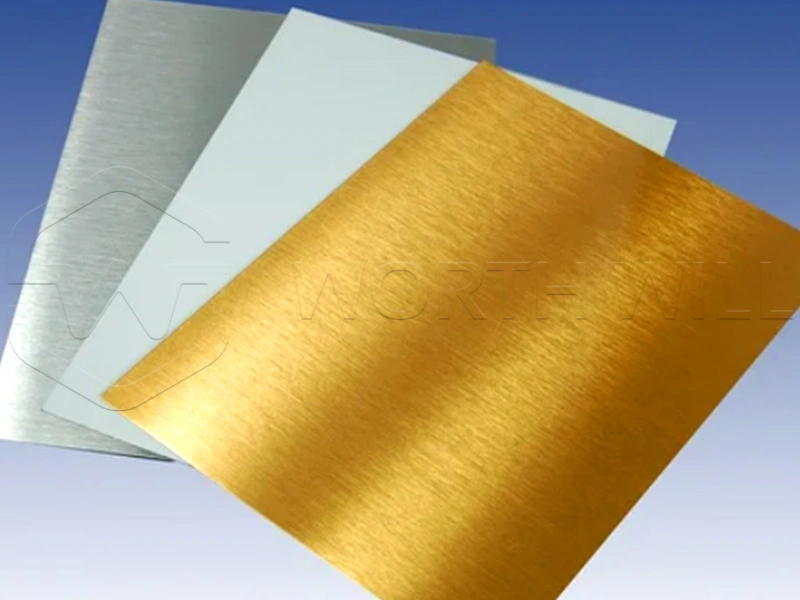

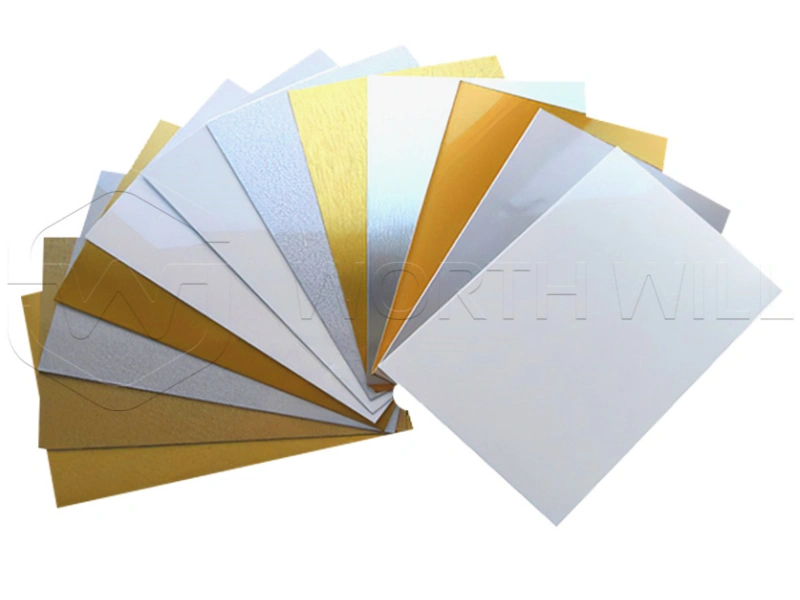

Finish

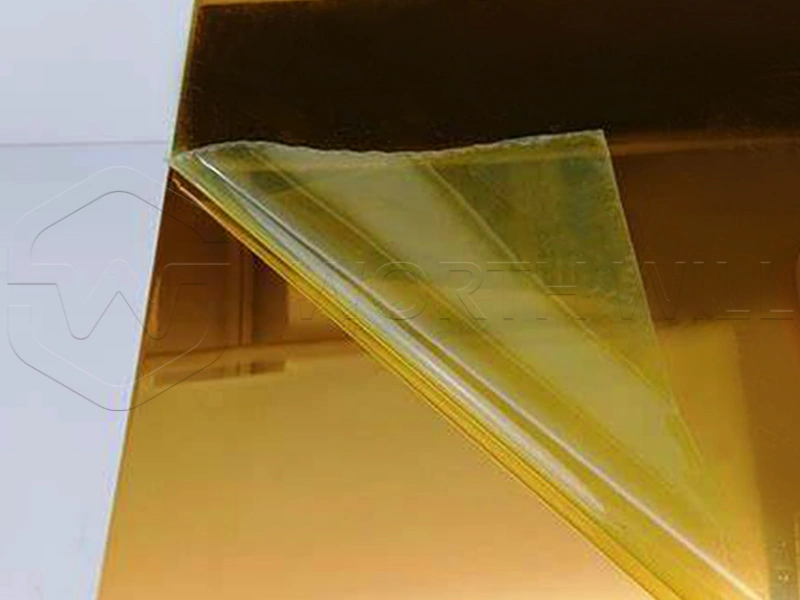

The surface finish dramatically impacts the final look of your sublimation print. Common finishes include:

- Glossy: Offers a high-sheen, reflective surface that enhances color vibrancy and luminosity, ideal for photographic prints.

- Matte: Provides a non-reflective, soft finish, reducing glare and often preferred for art reproductions or displays in brightly lit areas.

- Satin/Semi-Gloss: A middle ground between glossy and matte, offering some sheen without excessive reflection.

- Brushed: Features a textured, directional grain that adds a unique artistic touch, often used for industrial-style signage or decorative panels.

- White Base: The most common, offering a clean, bright background for true color representation.

- Silver/Clear Base: Allows the metallic properties of the aluminum to show through in lighter areas, creating a distinctive, luminous effect.

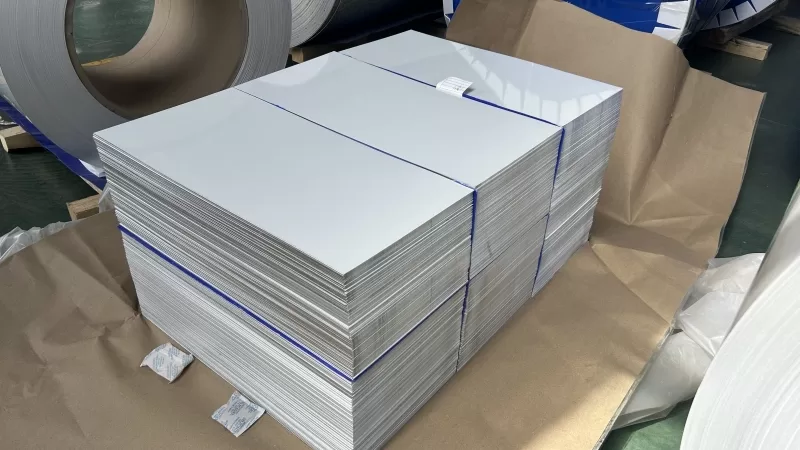

Shape and Size

Aluminum sublimation metal sheet suppliers offer sheets in various standard sizes, from small blanks for keychains to large panels for commercial signage. Many suppliers also provide custom cutting services, allowing you to get precise shapes and dimensions tailored to your project. This flexibility is invaluable for specialized applications.

Alloys Used in Aluminum Sublimation Sheets

While the crucial part for sublimation is the polymer coating, the base aluminum sheet itself is made from specific alloys. The alloy chosen by aluminum sublimation metal sheet suppliers affects the sheet’s inherent properties, such as formability, strength, and corrosion resistance before the coating is applied.

Common Alloys

- Alloy 1100: This is a commercially pure aluminum alloy known for its excellent workability, good corrosion resistance, and high thermal conductivity. It’s often used for general-purpose applications where strength is not the primary concern.

- Alloy 3003: A widely used alloy, 3003 offers good strength, excellent corrosion resistance, and good formability. It’s a popular choice for various sheet applications, including those that are later coated for sublimation.

- Alloy 5052: This alloy is stronger than 3003 and boasts superior corrosion resistance, especially in marine environments. It’s preferred for applications requiring higher strength and durability.

Most sublimation sheets will use alloys that provide a good balance of formability for manufacturing and a smooth, stable surface for the coating process. Reputable aluminum sublimation metal sheet suppliers will be able to provide details on the specific alloy used for their products.

Key Applications of Aluminum Sublimation Metal Sheets

The versatility and quality of aluminum sublimation sheets make them suitable for a vast array of uses across different sectors.

- Photography and Fine Art: Creating stunning, vibrant metal prints of photographs, portraits, landscapes, and fine art reproductions.

- Interior Decor and Home Goods: Used for decorative wall panels, custom backsplash tiles, table tops, coasters, and personalized home accents.

- Signage and Displays: Producing durable indoor and outdoor signs, directional signs, retail displays, informational plaques, and event signage.

- Personalized Gifts and Promotional Products: Manufacturing custom keychains, luggage tags, ornaments, business cards, and other unique giveaways.

- Awards and Trophies: Creating elegant and lasting award plaques, commemorative plates, and trophy inserts.

- Architectural and Design Elements: Incorporating into modern building facades, elevator panels, and custom furniture.

- Information and Identification: Used for asset tags, machinery labels, barcodes, and durable nameplates in industrial settings.

How to Choose the Right Aluminum Sublimation Metal Sheet Suppliers

Finding the ideal aluminum sublimation metal sheet suppliers is crucial for the success of your projects. Here are key factors to consider:

Product Quality

This is paramount. High-quality sheets should have a perfectly smooth, consistent coating free of defects, dust, or blemishes. The coating must also be receptive to ink and able to withstand the sublimation process without warping or discoloration. Ask for samples to test the print quality and durability.

Range of Products

A good supplier should offer a wide variety of sizes, thicknesses, and finishes to meet diverse customer needs. Custom cutting services are a significant plus, offering greater flexibility for unique projects.

Customer Service and Support

Responsive and knowledgeable customer service is invaluable. Look for suppliers who can answer technical questions, provide guidance on product selection, and offer efficient order processing and delivery. Good support indicates a reliable partner.

Pricing

While quality shouldn’t be compromised for price, competitive pricing is important, especially for bulk orders. Compare quotes from several aluminum sublimation metal sheet suppliers, but always weigh it against the quality and service offered.

Certifications and Standards

Check if the supplier adheres to industry standards or has relevant certifications. This can assure you of consistent quality, ethical manufacturing practices, and environmental responsibility.

What Are Aluminum Sublimation Metal Sheets?

Aluminum sublimation metal sheets are specially coated aluminum panels designed to accept dye-sublimation inks. Unlike traditional printing methods that lay ink on the surface, sublimation involves a chemical process where solid dyes are heated into a gas. This gas then penetrates the specialized polymer coating on the aluminum sheet, permanently bonding with it. The result is a vibrant, scratch-resistant, and incredibly durable image embedded into the coating, not just on top of it.

These sheets are often referred to as “sublimation blanks” because they are ready to be customized with any design. They offer a superior alternative to paper or canvas prints, especially when durability and a high-end look are desired. Many businesses and artists rely on aluminum sublimation metal sheet suppliers to source these essential materials.

Conclusion

Aluminum sublimation metal sheet suppliers are the gateway to creating stunning, highly durable, and versatile prints. These remarkable metal sheets, with their specialized coatings, unlock a world of possibilities for photographers, artists, sign makers, and businesses looking for premium, long-lasting visual solutions. By understanding the classifications, advantages, and applications of these sheets, and by carefully selecting a reputable supplier based on quality, range, service, and pricing, you can ensure your projects achieve the vibrant, professional results you desire. Embrace the future of printing with the exceptional quality of aluminum sublimation.