When it comes to industrial materials, aluminium strips are incredibly versatile. They are used in countless applications, from electrical systems to construction projects. If you’re looking for a specific size like an aluminium strip 25mm x 3mm, understanding the factors that influence its price is crucial.

Understanding Aluminium Strips: Size and Characteristics

An aluminium strip is a flat, narrow piece of aluminium, typically cut from a larger sheet or coil. The specific dimensions of 25mm x 3mm mean it is 25 millimeters wide and 3 millimeters thick. This particular size makes it suitable for a wide range of uses where a strong, lightweight, and corrosion-resistant material is needed.

Aluminium strips are valued for several key characteristics:

- Lightweight: Aluminium is significantly lighter than steel, which can reduce overall weight in applications.

- Corrosion Resistance: It naturally forms a protective oxide layer that prevents rust and corrosion.

- Good Conductivity: Aluminium is an excellent conductor of electricity and heat.

- Formability: It can be easily bent, cut, and shaped without losing its strength.

- Recyclability: Aluminium is highly recyclable, making it an environmentally friendly choice.

These properties, combined with the specific 25mm x 3mm dimensions, make this product a popular choice, and its price reflects its utility and material quality.

Classification of Aluminium Strips

Aluminium strips are classified based on several criteria, which directly impact their properties and ultimately, their aluminium strip 25mm x 3mm price. Understanding these classifications is key to specifying the right material for your project.

By Dimensions

The most obvious classification is by dimension. While we are focusing on 25mm x 3mm, aluminium strips come in a vast array of widths and thicknesses to suit different engineering and manufacturing needs. This specific size is quite common for applications requiring a balance of strength and flexibility.

By Temper

Temper refers to the hardness or strength of the aluminium strip, achieved through heat treatment or mechanical working. Common tempers include:

- “O” (Annealed/Soft): Very soft and ductile, easy to form.

- “H” (Strain Hardened): Hardened by cold working, with numbers indicating the degree of hardness (e.g., H14, H18, H24). H14 is a common temper for general purpose strips.

- “T” (Heat-Treated): Strengthened by heat treatment, often used for structural applications (e.g., T6).

The required temper will influence the manufacturing process and thus the aluminium strip 25mm x 3mm price. Harder tempers often require more processing.

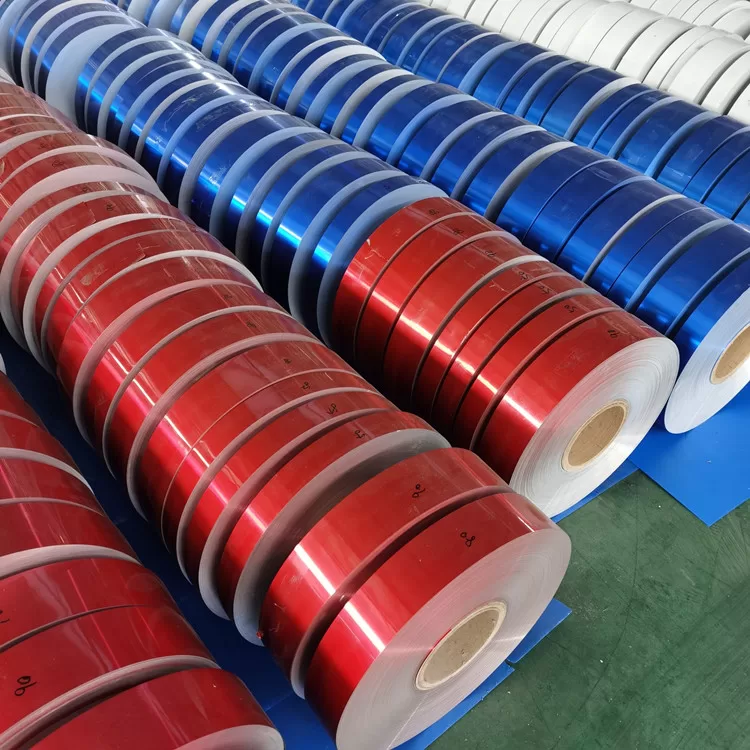

By Surface Finish

The surface finish of an aluminium strip can also vary:

- Mill Finish: This is the natural finish as it comes off the rolling mill. It’s often dull or slightly textured.

- Brushed or Polished: Achieved through mechanical finishing for a more aesthetic or specific functional purpose.

- Anodized: An electrochemical process that thickens the natural oxide layer, enhancing corrosion resistance and allowing for coloring.

- Coated: Applied with paint, lacquer, or other protective layers.

Special finishes will add to the overall aluminium strip 25mm x 3mm price.

Alloy: The Core of Aluminium Strip Quality and Price

The specific alloy used is perhaps the most significant factor determining an aluminium strip’s properties and its 25mm x 3mm price. An alloy is a mixture of aluminium with small amounts of other elements (like copper, magnesium, silicon, manganese, zinc). These elements enhance specific characteristics.

Here are some common aluminium alloys used for strips and how they might affect the price:

- 1xxx Series (e.g., 1050, 1060): These are commercially pure aluminium alloys (99% or more pure).

- Properties: Excellent electrical and thermal conductivity, high corrosion resistance, very good formability, but relatively low strength.

- Common Uses: Electrical conductors, heat exchangers, chemical equipment.

- Price Impact: Generally among the lower-priced options due to simpler alloying.

- 3xxx Series (e.g., 3003, 3004): Alloyed with manganese.

- Properties: Good strength (about 20% stronger than 1xxx series), excellent workability, good corrosion resistance. Non-heat-treatable.

- Common Uses: General purpose, cookware, storage tanks, building materials.

- Price Impact: Moderate aluminium strip 25mm x 3mm price, widely available.

- 5xxx Series (e.g., 5052, 5083): Alloyed with magnesium.

- Properties: High strength, excellent corrosion resistance (especially in marine environments), good weldability.

- Common Uses: Marine applications, automotive parts, pressure vessels, aircraft components.

- Price Impact: Higher price due to enhanced properties and more complex alloying.

- 6xxx Series (e.g., 6061, 6063): Alloyed with silicon and magnesium, heat-treatable.

- Properties: Medium to high strength, good corrosion resistance, excellent weldability, good machinability.

- Common Uses: Structural components, architectural applications, frames, pipelines.

- Price Impact: Often among the higher-priced aluminium strip 25mm x 3mm options due to strength and heat-treatment requirements.

The choice of alloy is critical for performance and directly influences the manufacturing complexity, thereby impacting the final price.

Key Factors Influencing Aluminium Strip 25mm x 3mm Price

The price of an aluminium strip 25mm x 3mm is not static. Many variables contribute to its final cost.

- Raw Material Prices: The global market price of aluminium (often dictated by exchanges like the London Metal Exchange – LME) is the most significant factor. Fluctuations in supply and demand for primary aluminium directly impact strip prices.

- Alloy Composition: As discussed, certain alloys containing more expensive alloying elements (like magnesium or copper) or requiring more complex processing will naturally have a higher price.

- Temper and Heat Treatment: Achieving specific tempers, especially those requiring extensive heat treatment, adds to manufacturing costs.

- Surface Finish Requirements: Polishing, anodizing, or applying special coatings are additional processes that increase the price.

- Quantity Ordered: Like most industrial products, purchasing larger quantities of aluminium strip 25mm x 3mm often results in a lower per-unit price due to economies of scale in manufacturing and shipping.

- Manufacturing Tolerances and Quality: Strips produced with tighter dimensional tolerances or higher surface quality standards might cost more due to more stringent production processes and quality control.

- Supplier and Location: Different suppliers will have varying pricing structures based on their production costs, overheads, and logistics. Shipping costs based on geographical location also play a role in the final price.

- Market Demand and Economic Conditions: Overall economic health and specific industry demand for aluminium products can cause price fluctuations.

Common Applications of 25mm x 3mm Aluminium Strips

The specific dimensions of 25mm x 3mm make this aluminium strip suitable for numerous applications across various industries. Its versatility often justifies its price.

- Electrical and Electronic Industry:

- Busbars: Used for conducting electricity in power distribution systems.

- Transformer Windings: Due to excellent conductivity and lightweight properties.

- Connectors and Terminals: For various electrical components.

- Construction and Architecture:

- Trims and Edging: Decorative or protective edges for floors, walls, and furniture.

- Window and Door Frames: Lightweight yet strong structural components.

- Roofing Components: Flashings and support elements.

- Automotive Industry:

- Heat Shields: To protect sensitive components from engine heat.

- Interior Trim: Lightweight decorative elements.

- Small Structural Brackets: Where lightweight strength is needed.

- Solar Energy:

- Mounting Systems: Lightweight frameworks for solar panels.

- Conductor Strips: In some panel designs.

- General Fabrication and Manufacturing:

- Brackets and Supports: For various assemblies.

- Shims and Spacers: For precise alignment in machinery.

- Signs and Displays: As framing or support elements.

- Machinery Parts: Components where corrosion resistance and strength are important.

How to Get the Best Aluminium Strip 25mm x 3mm Price

Finding the right balance between price and quality is essential. Here are tips to ensure you get the best value for your aluminium strip 25mm x 3mm purchase:

- Clearly Define Your Specifications: Be precise about the alloy, temper, surface finish, and quantity. Unclear specifications can lead to misquotes or unsuitable material.

- Request Multiple Quotes: Contact several reputable suppliers to compare their aluminium strip 25mm x 3mm price. Don’t just go for the lowest; consider their reputation, delivery times, and customer service.

- Consider Bulk Purchasing: If your project allows, buying in larger quantities often unlocks significant discounts on the per-unit price.

- Negotiate: Don’t hesitate to negotiate, especially for large orders.

- Understand Lead Times: Sometimes, a slightly higher price might come with faster delivery, which can save money in project delays.

- Check Certifications: Ensure the supplier can provide material test reports and certifications (e.g., ISO, ASTM standards) to guarantee quality and conformity, preventing issues down the line that could increase your overall cost.

- Monitor Market Trends: Keeping an eye on global aluminium market prices can help you decide the best time to purchase.

Conclusion

The aluminium strip 25mm x 3mm is a fundamental material for countless industrial and commercial applications. Its price is influenced by a complex interplay of factors, including raw material costs, the specific alloy chosen, manufacturing processes, and market dynamics. By understanding these elements, and by carefully specifying your needs and comparing options from various suppliers, you can ensure you secure high-quality aluminium strip 25mm x 3mm at the most competitive price, optimizing your project’s budget and performance.