Alloy 3003 H14 is a widely used aluminum alloy sheet and coil, known for its excellent corrosion resistance, moderate strength, and good formability. It belongs to the 3000 series aluminum alloys, primarily alloyed with manganese.

This alloy is used across construction, transportation, decorative, and industrial applications due to its combination of durability and workability. Understanding its properties, thickness options, and applications helps buyers select the right material.

3003 H14 Alloy

| Property | 3003-H14 | 5052-H32 | 6061-T6 |

|---|---|---|---|

| Composition | Al-Mn | Al-Mg | Al-Mg-Si |

| Tensile Strength (MPa) | 130–180 | 210–250 | 310–350 |

| Yield Strength (MPa) | 90–130 | 130–160 | 275 |

| Corrosion Resistance | Excellent | Excellent | Good |

| Formability | Excellent | Good | Moderate |

| Applications | Roofing, siding, tanks | Marine, automotive | Structural, aerospace |

Note: 3003-H14 is strain-hardened, providing moderate strength while keeping excellent formability.

3003-H14 Aluminum Sheet Specifications

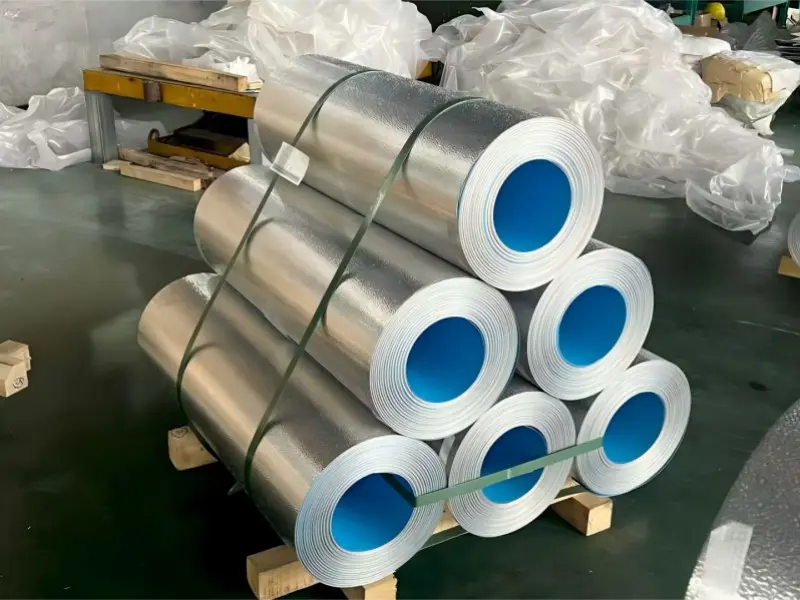

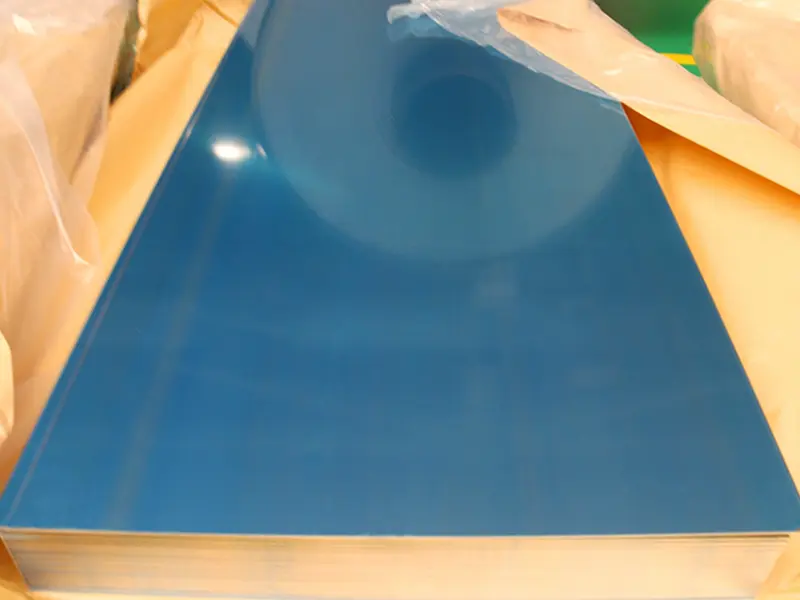

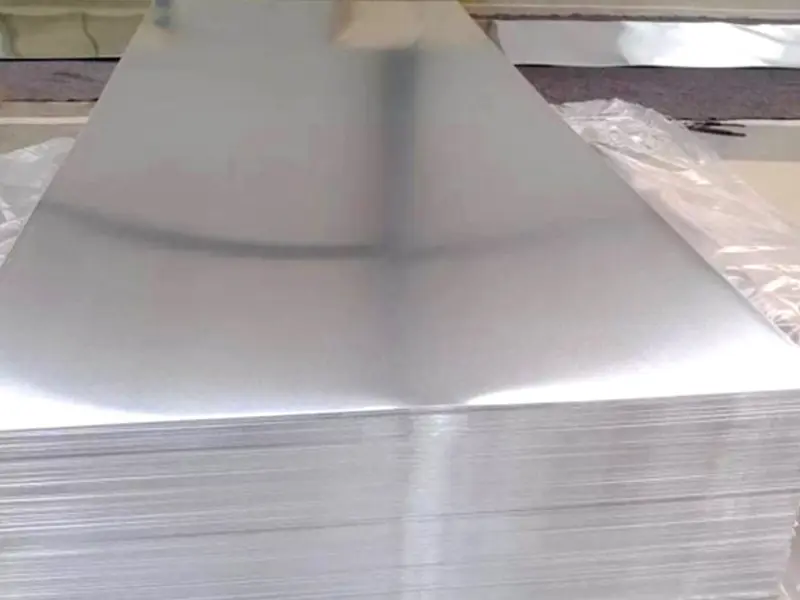

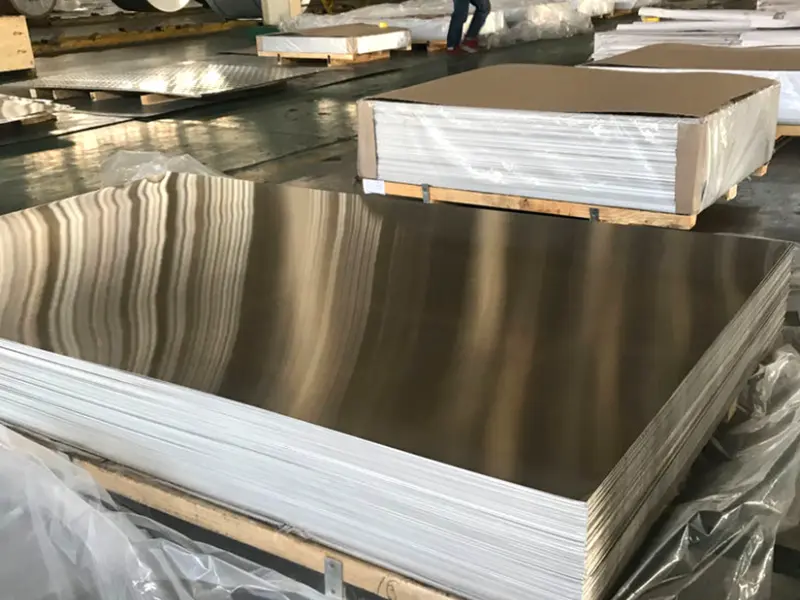

| Type | Thickness | Width | Finish | Features |

|---|---|---|---|---|

| Sheet | 0.5–6 mm | 1000–1500 mm | Mill Finish, Painted | Lightweight, corrosion-resistant |

| Coil | 0.3–3 mm | 500–1500 mm | Mill Finish, Embossed | Flexible, easy for forming and fabrication |

| Tread Plate | 2–6 mm | 1000–1500 mm | Diamond or Stucco | Anti-slip, durable |

3003-H14 Aluminum Sheet Thickness Options

Common thickness ranges for sheets and coils:

| Thickness Range | Common Applications |

|---|---|

| 0.5mm – 1.0mm | Food containers, decorative parts |

| 1.2mm – 2.0mm | Automotive panels, roofing |

| 2.5mm – 3.0mm | Truck bodies, industrial equipment |

| 3.0mm+ | Marine applications, heavy-duty structures |

3003-H14 vs Other Aluminum Alloys

3003-h14 vs 5052-h32

| Property | 3003-H14 | 5052-H32 |

|---|---|---|

| Strength | Moderate | Higher |

| Corrosion Resistance | Good | Excellent (marine grade) |

| Formability | Excellent | Good |

| Typical Use | General fabrication | Marine applications |

3003 h14 aluminum vs 6061

| Property | 3003-H14 | 6061 |

|---|---|---|

| Strength | Moderate | High |

| Heat Treatment | Not heat-treatable | Heat-treatable |

| Machinability | Fair | Excellent |

| Typical Use | Sheet metal work | Structural components |

Mechanical Properties

- Tensile Strength: 130–180 MPa

- Yield Strength: 90–130 MPa

- Elongation: 12–25% depending on thickness

- Density: 2.73 g/cm³

- Hardness: Moderate, suitable for forming and bending

Applications of Alloy 3003 H14

Alloy 3003 H14 is versatile and widely used in:

- Construction & Architecture: Roofing sheets, siding panels, ceilings

- Transportation: Truck bodies, trailers, fuel tanks

- Industrial Equipment: Ducts, tanks, chemical containers

- Decorative Panels: Wall cladding, signage, embossed aluminum

- Household Products: Roofing sheets, kitchen utensils, water heaters

| Application | Recommended Thickness | Type |

|---|---|---|

| Roofing & siding | 0.5–2 mm | Sheet or Coil |

| Tanks & containers | 1–3 mm | Sheet or Coil |

| Anti-slip flooring | 2–6 mm | Tread Plate |

| Decorative wall panels | 0.5–2 mm | Sheet |

FAQ

What is 3003 H14 material?

3003 H14 is an aluminum-manganese alloy with strain-hardened temper, offering moderate strength and excellent corrosion resistance.

What does H14 mean in aluminum?

H14 indicates strain-hardened temper to half-hard, meaning the material is moderately hardened by cold working without heat treatment.

What is 3003 alloy used for?

Common applications include roofing, siding, tanks, ducts, decorative panels, and kitchen utensils.

What is the difference between 3003 0 and 3003 H14?

- 3003-O: Annealed, soft, excellent formability, lower strength

- 3003-H14: Strain-hardened to half-hard, moderate strength, still good formability

How thick is 3003-H14 aluminum sheet?

It is available from 0.3 mm to 6 mm, depending on type (sheet, coil, tread plate) and application.

Why Choose Alloy 3003 H14

- Excellent corrosion resistance – suitable for outdoor applications

- Moderate strength – stronger than fully annealed aluminum while remaining easy to form

- Good workability – can be cut, bent, and embossed easily

- Cost-effective – ideal for roofing, siding, tanks, and decorative applications

- Wide availability – sheets, coils, and tread plates in multiple sizes

| Advantage | Explanation |

|---|---|

| Corrosion Resistance | Performs well in atmospheric, marine, and chemical environments |

| Strength | Moderate tensile and yield strength for structural use |

| Formability | Can be cut, bent, rolled, or embossed with ease |

| Versatility | Used in construction, industrial, decorative, and household products |

|

|