Unlock the Perfect Finish for Your Sublimation Projects

Choosing the right materials is key to any successful project, and sublimation printing is no exception. When it comes to creating stunning, durable metal prints, the aluminum sublimation sheet you select makes all the difference. With various options available, knowing which sheet best suits your needs can feel a bit overwhelming.

What is an Aluminum Sublimation Sheet? A Brief Overview

An aluminum sublimation sheet is a flat metal panel, usually made from aluminum, that has been specially pre-coated with a polymer layer. This unique coating is designed to absorb sublimation inks when heat and pressure are applied. Unlike regular printing that sits on the surface, sublimation printing infuses the ink into the coating, creating a vibrant, long-lasting, and highly durable image that is part of the material itself.

This process gives metal prints their signature qualities: exceptional color vibrancy, scratch resistance, and waterproof durability.

Key Factors in Choosing Your Aluminum Sublimation Sheet

To achieve the best results for your sublimation projects, pay close attention to these crucial specifications:

1. Finding the Right Size for Your Vision

The size of your aluminum sublimation sheet will depend entirely on your project’s dimensions and the capabilities of your sublimation printer and heat press.

- Standard Sizes: Manufacturers offer common precut sizes to fit popular applications. These often include dimensions like 8″x10″, 11″x14″, 12″x18″, 16″x20″, 24″x48″, and even larger sheets like 48″x96″ (for commercial use). Choosing standard sizes can be cost-effective and efficient.

- Custom Sizes: For unique projects, many suppliers can cut aluminum sublimation sheets to specific custom dimensions. This allows for less waste and perfect fitting, especially for architectural elements, large signage, or specialized art pieces.

- Maximizing Material: When buying larger sheets, consider how you can cut them down for multiple smaller projects. Planning your cuts carefully can reduce waste and save money.

Always measure your design and check your equipment’s platen size before ordering your aluminum sublimation sheet to ensure a perfect fit.

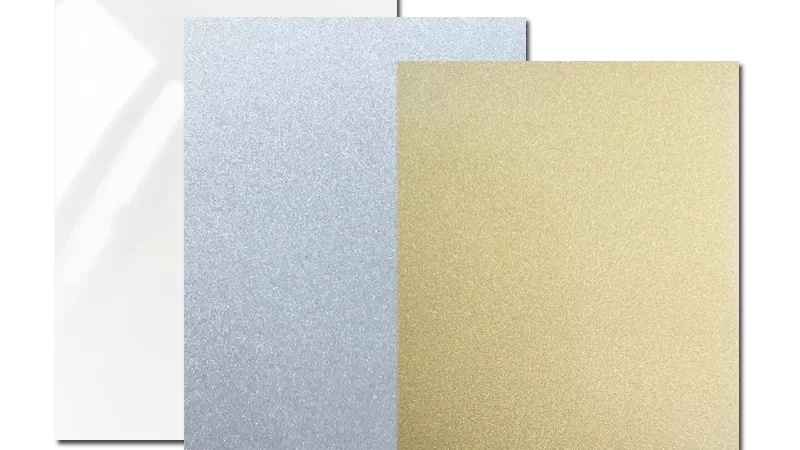

2. Understanding Coatings and Surface Finishes

- White Gloss:

- Description: The most popular finish, featuring a bright white base with a highly reflective, glossy surface.

- Effect on Print: Produces the most vibrant, intense colors with exceptional luminosity and depth. Reflections can add a dynamic quality but might create glare in bright light.

- Best For: High-impact photography, bright artwork, commercial displays, and anywhere you want colors to pop.

- White Matte:

- Description: A white base with a non-reflective, smooth, and subtle finish.

- Effect on Print: Offers softer, more subdued colors. It minimizes glare, making it ideal for high-light environments or for a more classic, fine art look.

- Best For: Portraits, areas with strong overhead lighting, and designs where glare is a concern.

- Clear Gloss (often referred to as “Silver” or “Brushed Silver”):

- Description: A transparent gloss coating applied directly to the natural aluminum surface. The metal’s silvery sheen shows through lighter areas of your image.

- Effect on Print: Creates a unique metallic effect, adding a luminous quality to white and light-colored areas of the design. Colors appear rich, but the overall tone will incorporate the silver.

- Best For: Black and white photography, industrial designs, modern art, and images where you want to incorporate the natural metallic look.

- Brushed (Clear Coated):

- Description: Features a distinctive brushed texture beneath a clear, glossy coating.

- Effect on Print: Combines the metallic sheen of clear gloss with a subtle, directional texture.

- Best For: Abstract art, signage with a premium feel, awards, and designs that benefit from a textured metallic backdrop.

Choosing the right coating is crucial for achieving your desired aesthetic for your sublimation sheets.

3. The Importance of Aluminum Alloy

While you might not specify the aluminum alloy directly when ordering, understanding its role is important for quality. The alloy refers to the specific mixture of metals used to create the aluminum sheet.

- Common Alloys: High-quality aluminum sublimation sheets typically use alloys like 1100 series or 3003 series aluminum.

- Why Alloy Matters: These specific alloys are chosen for their:

- Flatness: Ensuring the sheet remains perfectly flat during the heating process, preventing distortions in your print.

- Consistent Surface Quality: Providing a smooth, uniform base for the polymer coating.

- Excellent Workability: Making the sheets easier to cut and handle without compromising integrity.

- Good Corrosion Resistance: Contributing to the overall durability of the finished product.

A reputable supplier will always use a high-grade aluminum alloy as the foundation for their sublimation sheets, guaranteeing consistent performance and longevity.

4. Considering Thickness for Durability and Application

The thickness of your aluminum sublimation sheet affects its rigidity, weight, and suitability for different applications.

- 0.5mm (0.020 inches):

- Characteristics: Lightweight and relatively flexible.

- Best For: Smaller decorative items, photo panels that need to be mounted easily, or applications where weight is a concern. Easier to cut with hand tools.

- 0.7mm (0.028 inches):

- Characteristics: The most popular and versatile thickness. Offers a good balance of durability, rigidity, and manageable weight.

- Best For: General photo prints, medium-sized signage, awards, and most everyday sublimation projects.

- 1.0mm (0.040 inches):

- Characteristics: Provides superior rigidity and a substantial feel. Less prone to bending.

- Best For: Large-format prints, outdoor signage, architectural applications, and projects requiring maximum strength and impact resistance. Requires specialized cutting tools.

5. Other Quality Considerations

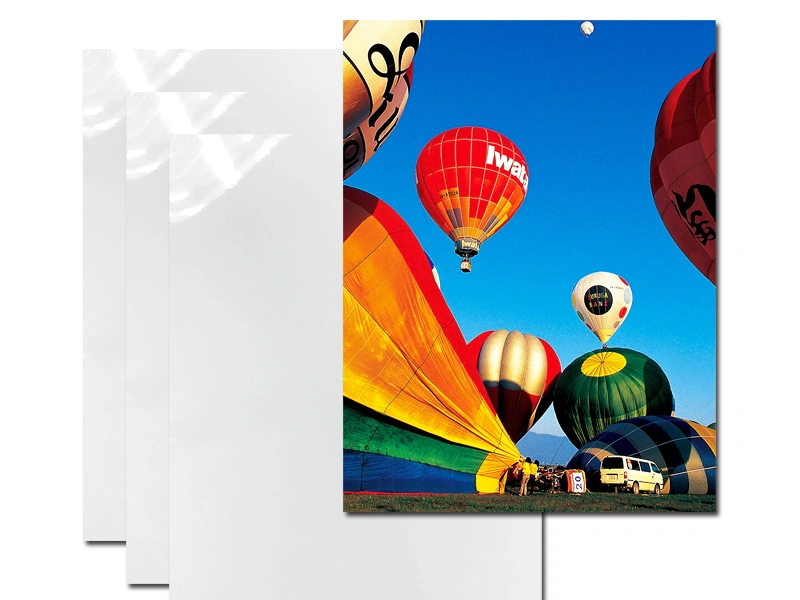

- Protective Film: Always ensure your aluminum sublimation sheets come with a clear protective film on the printable side. This prevents scratches during shipping and handling. Remember to peel it off before pressing!

- Quality Control: A good supplier will have strict quality control measures for both the raw aluminum and the coating process, ensuring consistent results every time.

Quick Reference Table for Choosing Your Aluminum Sublimation Sheet

| Feature | Options/Considerations | Best Use Cases |

|---|---|---|

| Size | Standard (e.g., 8×10, 11×14, 24×48) or Custom Cut | Match project dimensions, minimize waste, fit printer/press |

| Surface Finish | White Gloss: High vibrancy, reflective | Vibrant photos, commercial displays, high-impact art |

| White Matte: Reduces glare, softer look | Portraits, high-light areas, fine art aesthetics | |

| Clear Gloss: Metallic sheen shows through, transparent effect | B&W photos, industrial designs, modern art, incorporating metal look | |

| Brushed: Textured metallic look, unique depth | Abstract art, premium signage, awards, textured visuals | |

| Thickness | 0.5mm (0.020″): Lightweight, flexible | Small items, easy mounting, minimal weight needs |

| 0.7mm (0.028″): Standard, balanced rigidity/weight | General photo prints, medium signage, awards, versatile projects | |

| 1.0mm (0.040″): Maximum rigidity, heavy-duty | Large format, outdoor signage, architectural, maximum durability | |

| Aluminum Alloy | High-grade (e.g., 1100, 3003 series) | Ensures flatness, consistent coating, overall product quality |

| Protective Film | Always present on printable side | Essential for preventing scratches during transport and handling |

Make the Right Choice, Get the Best Results

Choosing the right aluminum sublimation sheet is a critical step towards producing high-quality, long-lasting metal prints. By carefully considering the size, selecting the perfect coating to match your artistic vision, understanding the importance of a quality aluminum alloy, and picking the appropriate thickness for your application, you can elevate your sublimation projects to a professional standard.

Don’t let the technical details hold you back. With this knowledge, you’re now ready to confidently select the ideal aluminum sublimation sheet and bring your designs to life with unparalleled clarity, vibrancy, and durability. Happy sublimating!