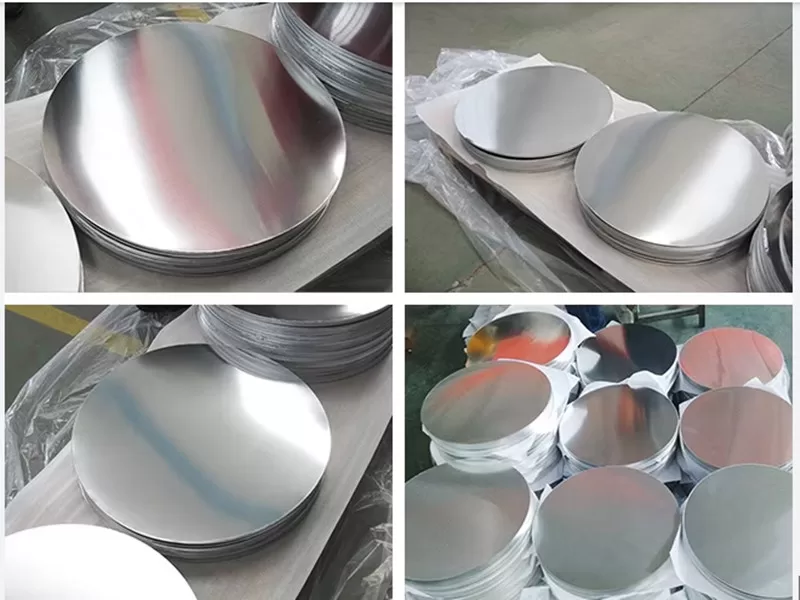

When it comes to cookware production, 1100 aluminum circle for cookware is a top choice for their strength, durability, and heat conductivity. Aluminum circles, especially those made from the 1100 alloy, are widely used in cookware manufacturing due to their unique properties that enhance cooking performance.

Why Choose 1100 Aluminum Circle for Cookware?

- High Thermal Conductivity

- The 1100 aluminum alloy has excellent thermal conductivity, allowing even heat distribution across the cookware surface. This ensures food cooks evenly, making it perfect for pans, pots, and other cooking tools.

- Pure and Safe Material

- With a high aluminum content (99.0% pure), 1100 aluminum is non-toxic and safe for food applications. It doesn’t corrode easily, making it a great choice for long-lasting cookware that remains safe over time.

- Excellent Workability

- 1100 aluminum circles are easy to press, spin, and shape into various cookware items. Their flexibility and malleability make them ideal for producing a wide range of kitchen products, including frying pans, saucepans, and stockpots.

- Lightweight and Durable

- Aluminum is known for being lightweight but strong, making it easy to handle while maintaining its structural integrity. This combination of lightness and strength is particularly beneficial for cookware, as it provides durability without the added weight.

- Affordability

- Compared to other materials, 1100 aluminum circles are affordable without compromising quality. This makes them an economical choice for manufacturers looking to produce cost-effective yet reliable cookware products.

Benefits of Buying from a Professional Aluminum Circle Factory

Purchasing aluminum circles directly from a reputable factory ensures you get high-quality, consistent products tailored to your specifications. Here’s why you should consider sourcing from a specialized aluminum circle manufacturer:

- Quality Control: Professional factories maintain strict quality control throughout the production process, ensuring each aluminum circle meets industry standards and provides reliable performance in cookware applications.

- Customization: Leading aluminum circle factories offer custom sizing, thicknesses, and tempering options to meet specific requirements, whether you need small circles for baking pans or larger ones for stockpots.

- Cost Efficiency: By purchasing directly from the factory, you avoid middleman costs and can often get better pricing, especially for bulk orders.

- Reliable Supply and Consistency: A professional factory can consistently supply high-quality aluminum circles in large quantities, making it easier for cookware manufacturers to maintain a stable production line.

Applications of 1100 Aluminum Circles in Cookware

- Frying Pans and Skillets: 1100 aluminum ensures even heating, preventing hot spots and allowing food to cook uniformly.

- Saucepans and Pots: The corrosion-resistant property of 1100 aluminum is ideal for items frequently in contact with liquids.

- Baking Trays and Cake Pans: Lightweight and easy to shape, aluminum circles are widely used in baking trays and various types of baking molds.

- Pressure Cookers and Stockpots: Aluminum circles provide a durable, safe, and effective material for larger cookware.

Quality from a Trusted Aluminum Circle Factory

Choosing 1100 aluminum circles from a trusted aluminum circle factory provides assurance in quality and durability for your cookware products. With exceptional workability, corrosion resistance, and thermal conductivity, 1100 aluminum circles are well-suited for a wide range of kitchen items.

Ready to enhance your cookware production? Partner with a professional aluminum circle manufacturer to get consistent, high-quality 1100 aluminum circles that elevate your product offerings.