Aluminum strips are versatile materials with a wide range of applications across industries due to their lightweight, corrosion-resistant, and malleable properties. The price of aluminum strips can vary depending on several factors, including market demand, raw material costs, processing methods, and product specifications. Let’s delve into the wide uses of aluminum strips and the factors that influence their price:

Uses of Aluminum Strips:

1. Construction and Architecture:

Aluminum strips are commonly used in construction and architecture for:

- Structural Components: Such as beams, columns, and framing members due to their strength-to-weight ratio and durability.

- Cladding and Facades: As exterior cladding panels or architectural features for their aesthetic appeal and weather resistance.

- Roofing and Siding: For their corrosion resistance, lightweight nature, and ability to withstand harsh weather conditions.

2. Electrical and Electronics:

Aluminum strips find applications in the electrical and electronics industry for:

- Conductors: As conductive strips or busbars in electrical wiring and power distribution systems due to their high conductivity and low electrical resistance.

- Heat Sinks: For dissipating heat in electronic components and devices, such as LED lights, computer processors, and power transistors.

3. Transportation and Automotive:

In the transportation and automotive sector, aluminum strips are used for:

- Body Panels: Including doors, hoods, and fenders for their lightweight, corrosion-resistant, and crash-absorbing properties.

- Extrusions: For manufacturing structural components, such as chassis, frames, and suspension parts, to reduce vehicle weight and improve fuel efficiency.

4. Packaging and Consumer Goods:

Aluminum strips are widely utilized in packaging and consumer goods for:

- Flexible Packaging: Such as foil pouches, blister packs, and sachets for food, pharmaceuticals, and personal care products.

- Household Items: Including containers, utensils, and foil wraps for cooking, baking, and food storage due to their impermeability and heat resistance.

5. Industrial and Manufacturing:

In industrial and manufacturing settings, aluminum strips are employed for:

- Machinery and Equipment: For fabricating components, parts, and assemblies requiring strength, durability, and corrosion resistance.

- Fabrication: Including stamping, bending, and welding into custom shapes and profiles for various applications in diverse industries.

Factors Influencing Aluminum Strip Price:

1. Market Demand and Supply:

Fluctuations in market demand and supply dynamics can significantly impact aluminum strip prices. Increased demand from sectors such as construction, automotive, and electronics can lead to higher prices, while oversupply may result in lower prices.

2. Raw Material Costs:

The cost of raw materials, particularly aluminum ingots, is a primary determinant of aluminum strip prices. Changes in global aluminum prices, driven by factors such as mining output, geopolitical events, and trade policies, can influence strip prices.

3. Processing and Manufacturing Costs:

The cost of processing and manufacturing aluminum strips, including extrusion, rolling, and finishing processes, affects their price. Energy costs, labor expenses, and overheads associated with production facilities also contribute to the final price.

4. Product Specifications and Quality:

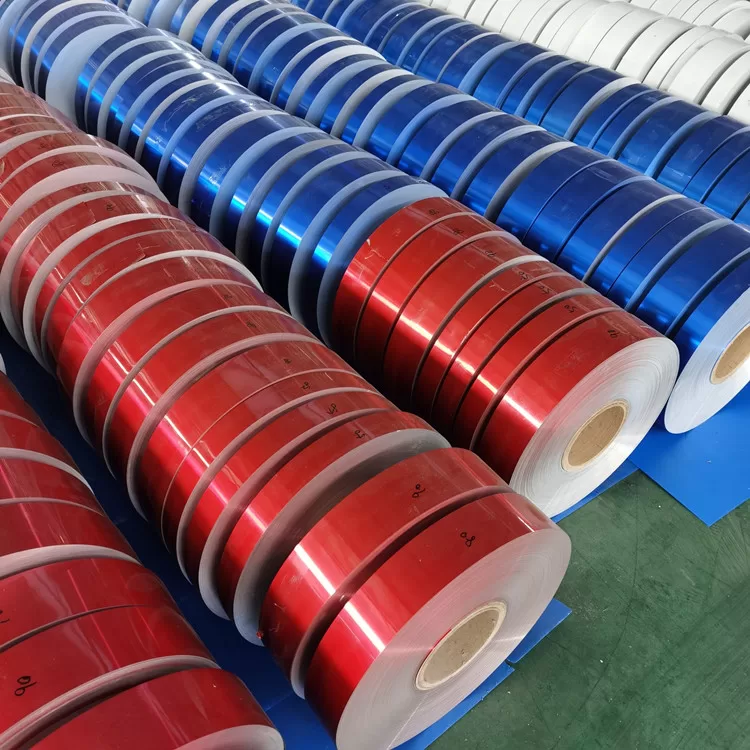

Aluminum strips with specific dimensions, thicknesses, alloys, and surface finishes may command higher prices due to customization and quality requirements. Premium-grade strips with superior mechanical properties and surface characteristics may also have higher price points.

5. Market Conditions and Economic Factors:

Macroeconomic factors, such as inflation, currency exchange rates, interest rates, and economic growth, can influence aluminum strip prices. Market sentiment, investor confidence, and geopolitical stability also play a role in price fluctuations.

6. Regulatory Compliance and Standards:

Compliance with regulatory standards and certifications, such as ASTM International specifications, may impact aluminum strip prices. Adherence to quality control measures, environmental regulations, and safety standards can affect production costs and, consequently, prices.

Conclusion:

Aluminum strips serve diverse applications across industries, from construction and electronics to transportation and packaging. The price of aluminum strips is influenced by various factors, including market demand, raw material costs, processing expenses, product specifications, and economic conditions. Understanding these factors is essential for stakeholders, including manufacturers, distributors, and end-users, to make informed decisions and effectively manage costs in the procurement and utilization of aluminum strips.