Aluminum sheet for sublimation truly offers a fantastic way to create vibrant, durable, and professional-looking prints. Whether you’re making personalized gifts, unique art pieces, or robust signage, the quality and longevity of sublimation on aluminum are unmatched. Embrace the brilliance of sublimation aluminum and elevate your creations today!

What is an Aluminum Sheet for Sublimation?

Hello! Are you looking for the best way to get amazing, long-lasting images on metal?

You’ve come to the right place! We’re talking about aluminum sheet for sublimation, a fantastic material that lets you print super bright and durable designs.

How Sublimation Works on Aluminum Sheets

Sublimation printing is a unique chemical process. It’s not like regular printing where ink sits on top of the material. Instead, with sublimation, the ink actually becomes part of the material. Here’s the simple breakdown when using an aluminum sheet for sublimation:

- Print: You start by printing your design onto special sublimation transfer paper using sublimation inks.

- Heat Press: This paper is then placed face down onto a specially coated sublimation aluminum blank.

- Heat & Pressure: The aluminum sheet and paper are put into a heat press. High heat (around 380-400°F or 193-204°C) and pressure are applied.

- Sublimation: The heat turns the solid sublimation ink directly into a gas (this is “sublimation”). This gas then infuses into the polymer coating of the aluminum sheet.

- Cool Down: When the aluminum cools, the ink returns to a solid form, permanently bonded within the coating.

The result is a print that is incredibly vivid, scratch-resistant, and won’t peel, crack, or fade easily. This makes sublimation aluminum ideal for products that need to last.

Why Choose Aluminum Sheets for Sublimation?

There are many reasons why aluminum sheets for sublimation are a top choice for high-quality printing projects:

- Durability: Unlike paper prints, sublimation aluminum is highly resistant to scratches, chemicals, moisture, and UV fading. Your images will look great for years.

- Vibrant Colors: The special polymer coating on the sublimation aluminum panel allows inks to achieve exceptional color depth and clarity, producing truly stunning visuals.

- Lightweight & Strong: Aluminum is a light yet very strong metal, making it easy to handle, hang, and ship.

- Modern & Professional Look: The sleek, metallic finish of sublimation aluminum gives a premium and contemporary feel to any design.

- Versatility: Available in various finishes and thicknesses, coated aluminum sheets can be used for many different items.

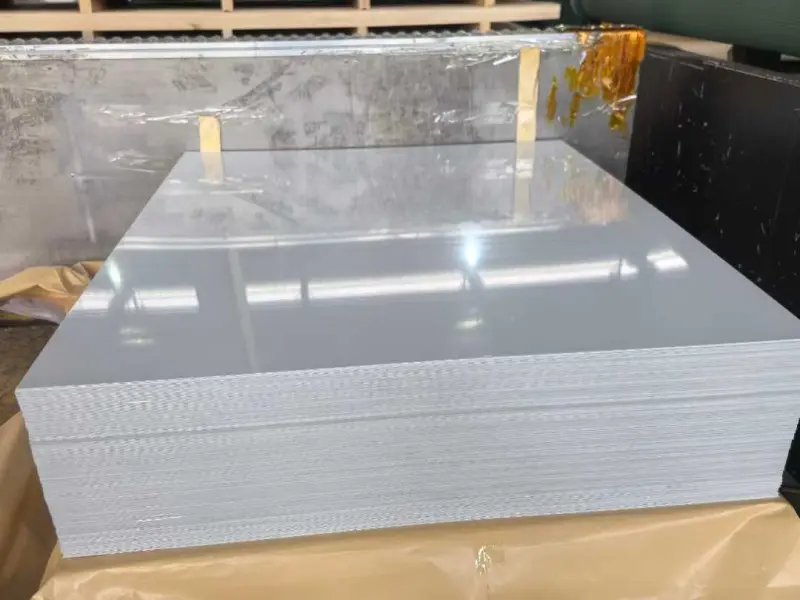

Types and Specifications of Aluminum Sheets for Sublimation

To help you choose the right aluminum sublimation blanks for your needs, here’s a table showing common types and their specifications. These numerical specifications are important for matching the right product to your printing requirements.

| Type of Aluminum Sheet | Thickness (mm) | Finish Options | Coating Type | Common Sizes (inches) | Key Features |

|---|---|---|---|---|---|

| Standard Gloss White | 0.5 – 1.2 | High Gloss | Polyester Polymer | 8×10, 11×14, 16×20, 24×36 | Brightest colors, reflective, classic photo look. |

| Standard Matte White | 0.5 – 1.2 | Matte | Polyester Polymer | 8×10, 11×14, 16×20, 24×36 | Reduced glare, soft finish, modern art feel. |

| Brushed Silver | 0.7 – 1.0 | Brushed Metallic (Silver) | Clear Polyester Polymer | 5×7, 8×10, 12×18 | Unique metallic texture shows through image, elegant. |

| Gloss Clear | 0.5 – 1.0 | High Gloss | Clear Polyester Polymer | 8×10, 11×14, 16×20 | Metal shows through light areas, vibrant colors, industrial look. |

| Outdoor/Heavy Duty | 1.5 – 3.0 | Gloss or Matte | UV-Resistant Polyester Polymer | Up to 48×96 | Extra durable for outdoor signs, weather-resistant. |

| Magnetic Sublimation | 0.5 – 0.7 | Gloss White, Matte White | Polyester Polymer, with magnetic backing | Various small sizes | Turns any surface into a magnetic display. |

| ChromaLuxe Panels | 1.0 – 1.5 | High Gloss, Mid-Gloss, Matte, Sheer | Proprietary Polymer Coating | Up to 60×120 | Industry-leading vibrancy and archival quality. |

Note: Thicknesses and sizes are typical and can vary by manufacturer. Always check product details.

Applications of Aluminum Sheets for Sublimation

The versatility of sublimation aluminum sheets means they are used in a wide array of fields. Here are some popular sublimation applications:

- Photography and Art Displays: Create stunning metal photo prints with incredible depth and detail.

- Indoor and Outdoor Signage: Durable and weather-resistant signs for businesses, events, and public spaces.

- Personalized Gifts: Custom photo gifts, awards, plaques, and decorative items.

- Architectural Décor: Wall panels, backsplashes, and decorative elements in homes and offices.

- Promotional Products: Branded items, display boards, and unique marketing materials.

- Industrial Labels & Tags: Durable labels that can withstand harsh environments.

- Jewelry and Accessories: Custom pendants, earrings, and other personalized accessories.

- Custom Trophies and Awards: High-end, personalized recognition items.

Choosing the Right Aluminum Sheet for Your Project

Selecting the best sublimation aluminum for your specific project is key to a great outcome. Consider these factors:

- Project Type: Is it an indoor photo display or an outdoor sign? This will influence the required durability and UV resistance.

- Desired Finish: Do you want a shiny, reflective look (gloss) or a softer, non-reflective appearance (matte)? Do you prefer the raw metallic look to show through (brushed silver, clear)?

- Thickness: Thinner sheets (0.5mm) are often used for decorative items or smaller prints, while thicker sheets (1.0mm+) provide more rigidity and are better for larger displays or outdoor use.

- Budget: Prices can vary based on size, thickness, and specialized coatings.

Always ensure the coated aluminum sheets you choose are specifically designed for sublimation to guarantee proper ink adhesion and vibrant results.

Tips for Successful Sublimation on Aluminum

To achieve perfect sublimation prints on your aluminum sheet for sublimation, follow these important tips:

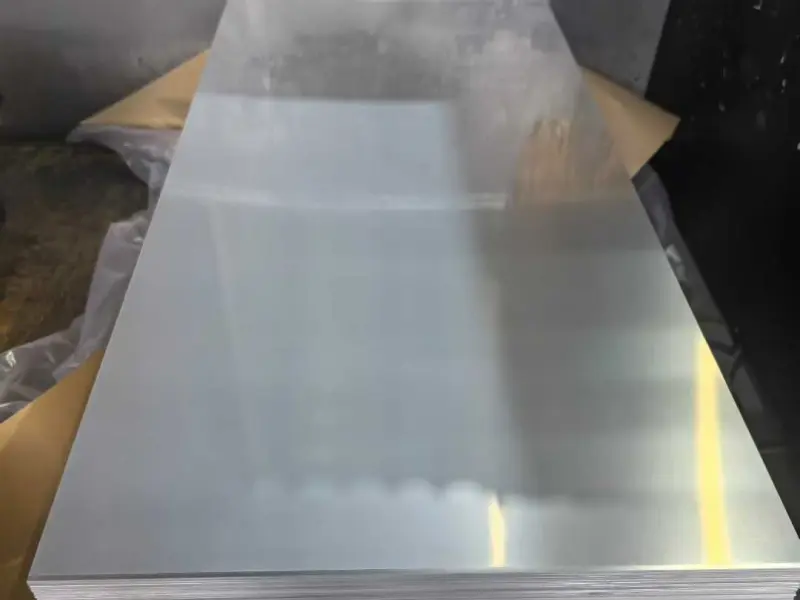

- Cleanliness is Key: Before printing, ensure your sublimation aluminum blank is perfectly clean and free of dust, fingerprints, or smudges. Use a lint-free cloth and a specialized cleaner if necessary.

- Protective Film: Most aluminum blanks come with a protective plastic film. Remember to remove this film before pressing!

- Proper Settings: Always refer to the manufacturer’s recommended time, temperature, and pressure settings for your specific sublimation aluminum panel and heat press. Typical temperatures are around 190−205∘C (375−400∘F) for 45−90 seconds.

- Butcher Paper: Use butcher paper on top of and below your sublimation blank in the heat press. This protects your heat press from excess ink and helps absorb moisture.

- Avoid Ghosting: Secure your transfer paper to the aluminum blank using heat-resistant tape to prevent it from shifting during pressing, which can cause blurry or “ghosted” images.

- Ventilation: Work in a well-ventilated area, as the sublimation process can release fumes.

By following these sublimation tips, you’ll be well on your way to creating stunning, high-quality custom aluminum prints.