Introduction to 4×8 Sheet of 1/8 Inch Aluminum

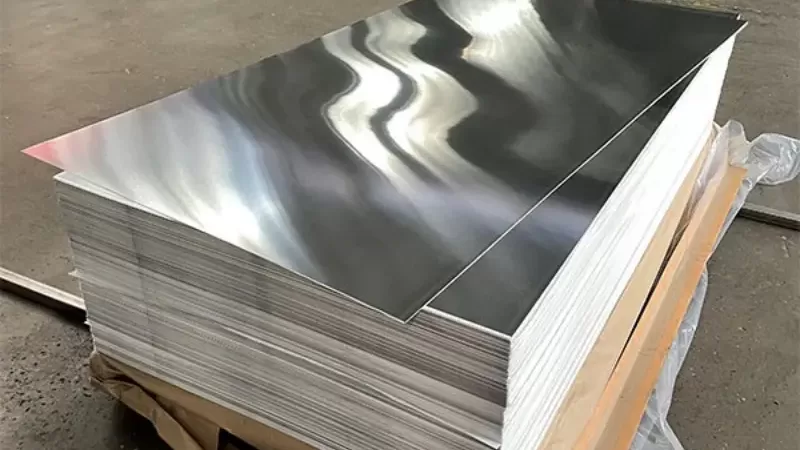

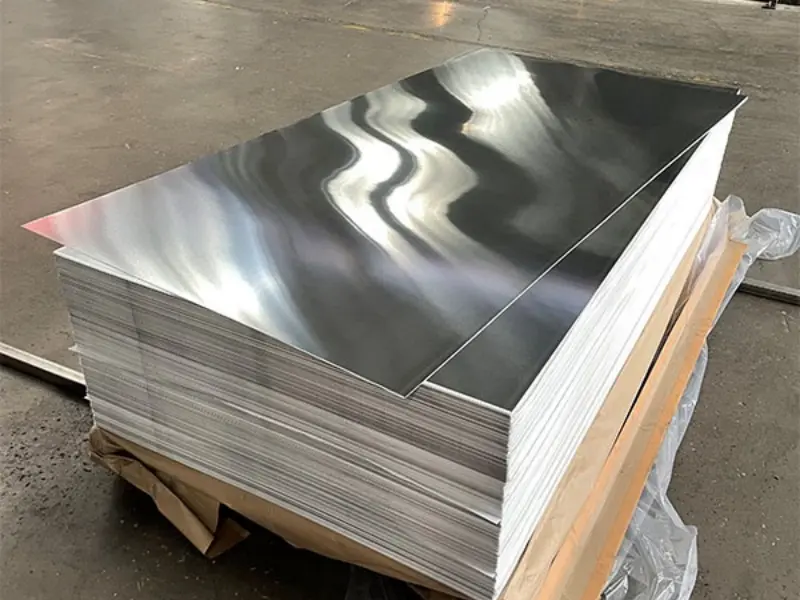

A 4×8 sheet of 1/8 inch aluminum is a standard-sized aluminum panel measuring 4 feet wide by 8 feet long with a thickness of 1/8 inch (3.175 mm). This size is widely used in construction, manufacturing, and DIY projects due to its versatility, ease of handling, and cost-effectiveness. The price of these sheets varies based on alloy type, market conditions, and supplier factors.

What is a 4×8 Sheet of 1/8 Inch Aluminum?

A 4×8 sheet of 1/8 inch aluminum refers to a flat piece of aluminum metal measuring 4 feet by 8 feet (121.92 cm x 243.84 cm) with a thickness of 1/8 inch (0.125 inches or approximately 3.175 mm). This specific dimension and thickness make it a very common and sought-after product in the metal supply industry.

It’s a versatile aluminum plate or aluminum sheet metal that offers a good balance of strength and manageability for many applications.

Why Choose 1/8 Inch Aluminum Sheets?

The 1/8 inch aluminum thickness is popular for several reasons:

- Strength and Rigidity: It’s thick enough to offer significant structural integrity and resistance to bending, making it more robust than thinner gauges.

- Weight: While strong, aluminum is naturally lightweight compared to steel. A 4×8 aluminum plate at 1/8 inch thickness is still manageable for many applications without adding excessive weight.

- Workability: This thickness is generally easy to cut, drill, and form using standard metalworking tools, offering good sheet metal fabrication potential.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, making it highly resistant to rust and corrosion, especially important for outdoor or marine environments.

Key Factors Affecting the Price of a 4×8 Sheet of 1/8 Inch Aluminum

The price of a 4×8 sheet of 1/8 inch aluminum isn’t fixed. It can vary significantly based on several factors. Understanding these will help you budget accurately and make informed purchasing decisions.

| Factor | Impact on Price |

|---|---|

| Aluminum Alloy Type | Different aluminum alloys have varying compositions and properties, directly affecting their cost. |

| Global Market Fluctuations | Aluminum is a commodity. Its material cost is tied to global supply and demand, energy prices, and geopolitical events. Prices can change daily or weekly. |

| Supplier Type | Buying from a large distributor or wholesaler often yields better prices than buying from a smaller local retailer, especially for larger quantities. Online suppliers might offer competitive pricing but consider shipping. |

| Quantity Purchased | Most suppliers offer discounts for bulk orders. Buying multiple 4×8 aluminum sheets at once can significantly reduce the aluminum sheet cost per square foot. |

| Finish | The basic “mill finish” (raw aluminum) is the least expensive. Options like anodizing, powder coating, polishing, or brushed finishes add to the cost due to extra processing. |

| Cutting & Fabrication | If you need custom cuts, specific shapes, bending, or drilling services, these will add to the aluminum sheet price. Custom sheet metal fabrication costs vary by complexity. |

| Shipping Costs | Due to its size and weight, shipping a 4×8 aluminum sheet can be a significant expense, especially for long distances. Always factor this into the total 4×8 aluminum sheet cost. |

| Location | Prices can vary geographically due to regional supply chains, local taxes, and transportation costs. |

Common Aluminum Alloys and Their Price Impact

The specific alloy of aluminum plays a major role in its cost per sheet. Here are some of the most common alloys you’ll find for a 4×8 1/8 inch aluminum plate:

| Alloy Type | Key Characteristics | Typical Price Impact |

|---|---|---|

| 3003 Aluminum | Good workability, excellent corrosion resistance, medium strength. Very common for general-purpose applications. | Generally the most affordable and widely available option for a 4×8 1/8 inch aluminum sheet. |

| 5052 Aluminum | Higher strength than 3003, excellent corrosion resistance (especially in marine environments), good formability. | Slightly more expensive than 3003 due to its higher strength and better corrosion resistance. A popular choice for marine and automotive uses. |

| 6061 Aluminum | High strength, good weldability, good corrosion resistance. Often heat-treatable for even greater strength. | Typically the most expensive of these common alloys. Used in structural components, aerospace, and high-stress applications where strength is key. |

Key Factors Affecting Price

- Aluminum Alloy: Different alloys (e.g., 3003, 5052, 6061) have varying costs.

- Market Prices: Global aluminum prices fluctuate due to supply and demand.

- Quantity: Bulk orders often receive discounts.

- Supplier: Prices differ between manufacturers, distributors, and retailers.

- Finish: Mill finish is standard; anodized or coated finishes cost extra.

Price Range for 4×8 Sheet of 1/8 Inch Aluminum

| Alloy | Price Range (Per Sheet) | Common Uses |

|---|---|---|

| 3003 | $150 – $250 | General fabrication, gutters |

| 5052 | $180 – $280 | Marine, automotive parts |

| 6061 | $200 – $320 | Structural applications, frames |

| 2024 | $250 – $400 | Aerospace, high-strength needs |

Note: Prices are estimates and may vary based on location and market conditions.

Additional Costs to Consider

- Cutting Fees: Custom sizing may incur charges.

- Shipping Costs: Weight and distance affect delivery fees.

- Taxes: Sales tax applies in most regions.

- Finish Options: Anodizing or coating adds $20-$100 per sheet.

Applications of 4×8 Aluminum Sheets

- Construction: Roofing, siding, and wall panels.

- Transportation: Truck trailers, vehicle bodies.

- DIY Projects: Furniture, signs, and crafts.

- Industrial: Machine guards, workbenches, enclosures.

FAQ Section

Q1: Why does the price vary by alloy?

A: Alloys have different compositions and properties. For example, 6061 is stronger and more expensive than 3003.

Q2: Can I get a discount for bulk orders?

A: Yes, suppliers often offer discounts for large quantities.

Q3: Does the price include cutting or machining?

A: No, cutting and machining are usually additional services with separate fees.

Q4: How does thickness affect the price?

A: Thicker sheets cost more due to increased material usage.

Q5: Where can I buy 4×8 aluminum sheets?

A: Metal suppliers, online retailers, and local hardware stores.

Q6: How do I calculate the weight of a sheet?

A: A 4×8 sheet of 1/8 inch aluminum weighs approximately 100-110 lbs (45-50 kg).

Tips for Saving Money

- Compare Suppliers: Check prices from multiple sources.

- Buy in Bulk: Larger orders often reduce the cost per sheet.

- Choose Standard Alloys: 3003 and 5052 are more affordable than 6061 or 2024.

- Avoid Custom Finishes: Mill finish is cheaper than anodized or coated options.

How to Get the Best 4×8 Sheet of 1/8 Inch Aluminum Price

Finding competitive pricing requires a bit of research. Here are some tips:

- Shop Around: Get quotes from multiple metal suppliers, both local and online. Don’t just check one place.

- Specify Your Needs Clearly: Be precise about the alloy, finish, and any cutting or fabrication services you require.

- Consider Quantity: If you have ongoing needs, buying in bulk might save you money per sheet, reducing your overall aluminum sheet cost.

- Check for Discounts: Ask about volume discounts or special offers for new customers.

- Factor in Shipping: Always get a final quote that includes shipping costs to compare apples to apples. Sometimes a slightly higher per-sheet price from a local supplier is cheaper once shipping from an online vendor is added.

- Understand Market Trends: Keep an eye on general aluminum market trends if you’re planning a large purchase, as prices can fluctuate.

Where to Purchase Your Aluminum Sheet

- Local Metal Suppliers: Often offer personalized service, ability to pick up directly (saving shipping), and advice. Good for smaller orders or custom work.

- Online Metal Distributors: Can offer a wider selection and competitive pricing, especially for standard sizes. Shipping costs will apply.

- Industrial Supply Stores: Some larger industrial suppliers or hardware chains might carry common sizes, but selection can be limited.

- Specialty Fabricators: If you need complex custom cuts or bending, a dedicated sheet metal fabrication shop might be your best bet, as they can supply the material and perform the work.