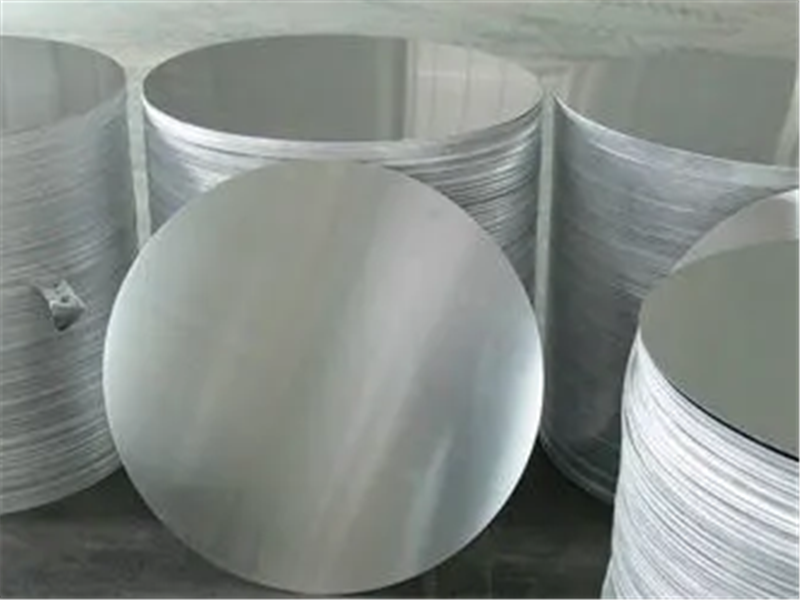

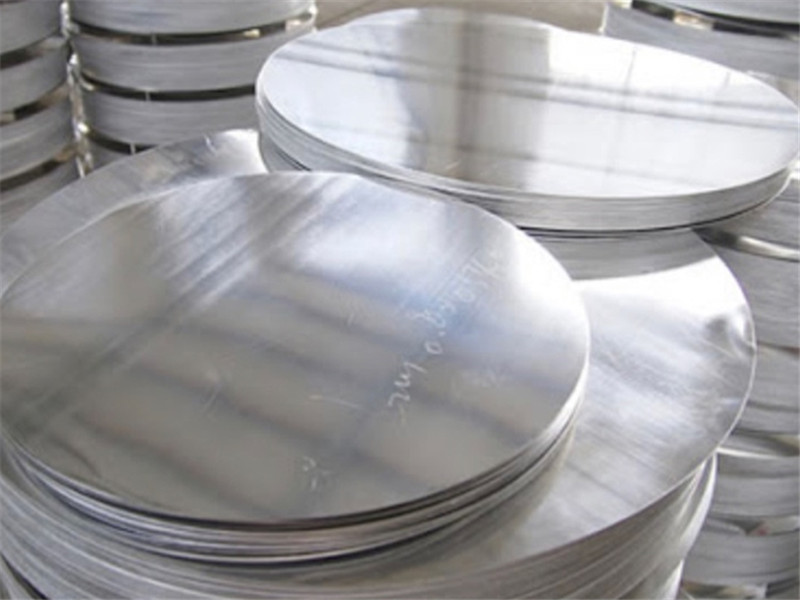

In the life we are in contact with, there are many aluminum discs, but we do not notice them. There are also many types of concatenated discs. For example, it’s the most common in our life. Lamps, tableware, lampshades, etc. are all made of aluminum wafers.

Advantages Of Aluminum Circles

But you may not know the advantages of aluminum wafers. Today, aluminum wafer manufacturers will conduct a centralized summary to explain the aluminum wafers in detail.

- Light density of aluminum disc

The density of the aluminum disc is takes 1 series, 3 series, 5 series and 8 series as material. We stamp alloy aluminum plate and strip. Therefore, the metal density of aluminum discs is generally about 2.71, which is the lowest among the aluminum metals we commonly use, and has better form-ability than iron metals. And is lighter than steel.

2. The performance of aluminum wafers

We all know that aluminum wafers are more suitable, and the most commonly used stamping performance in our life. So the original sheet has good stamping performance in terms of performance, and its stamping performance is also the use of the original sheet, which is the most widely used. So we are for The stamping performance of aluminum wafers is particularly important.

3. Form ability of aluminum wafers

We all know that aluminum discs have good performance in bending, bending performance, tensile bending performance.

4. Corrosion resistance of aluminum discs

With the advantages of aluminum, aluminum discs also have the advantages of corrosion resistance. When used in lamps and lanterns, under the long-term light source of the lamp, the opposition does not have much influence on the interior. So the aluminum disc has great corrosion resistance in reporting loss, and the light density. It’s widely used in the field of kitchen originals, the originals have great corrosion resistance. Therefore, aluminum discs are also suitable for the production of kitchen fumes. Under the harsh environment of high temperature and high temperature, aluminum discs are still It can guarantee a long life span of up to 15 years. Therefore, aluminum discs have extremely high corrosion resistance in the field of kitchen utensils, lamps and other fields.

5. Tensile properties of aluminum discs

We all know that aluminum discs have great tensile properties. Depending on the process of the aluminum circle, when the annealed state of the aluminum circle reaches, the original piece has great tensile properties. In terms of high-strength stretching, we can stretch the aluminum circle. This performance is brought to the extreme, so we say that the tensile properties of aluminum discs are very suitable. We hope that aluminum wafers can gain greater popularity, so that aluminum wafers can be used in a wider range of tensile properties.