Dye sub aluminum sheet is an aluminum sheet treated with a dyed acrylic coating process. It has excellent color retention and durability. This makes it suitable for a variety of printing and decoration applications.

Product description of dye sub aluminum sheet

Dye sub aluminum sheet is an aluminum sheet specially coated with a sublimation coating, allowing it to accept dye sublimation inks. The dye sublimation process heats the ink to a high temperature. This causes the ink to transform into a gas without passing through a liquid state. This gas then permeates the surface of the coated aluminum sheet and becomes embedded within the coating, resulting in vibrant and long-lasting color reproduction. Businesses commonly use dye sub aluminum sheets for signage, photography, awards, and personalized gifts. These applications benefit from high-resolution images, intricate designs, and vibrant colors.

Specification of dye sub aluminum sheet

| Product name | Dye sub aluminum sheet |

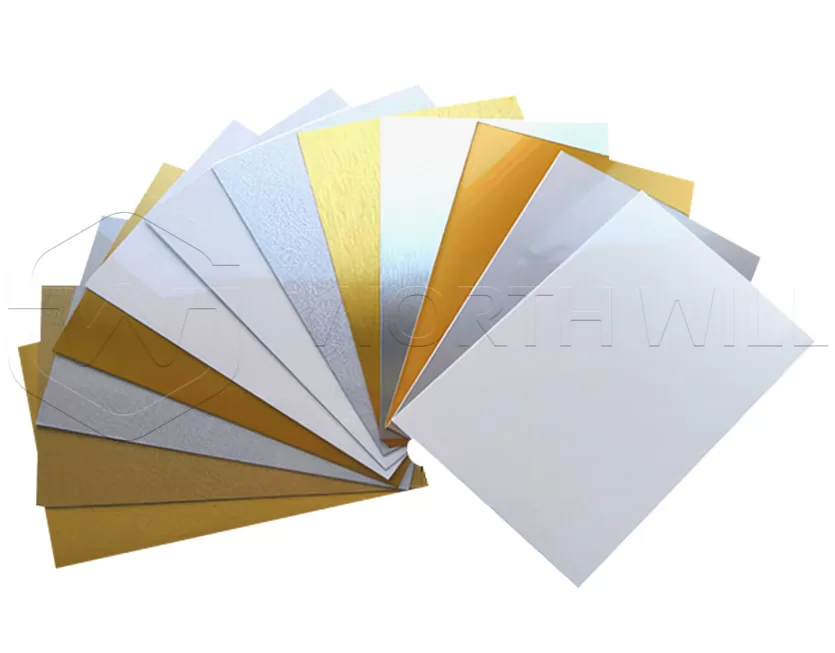

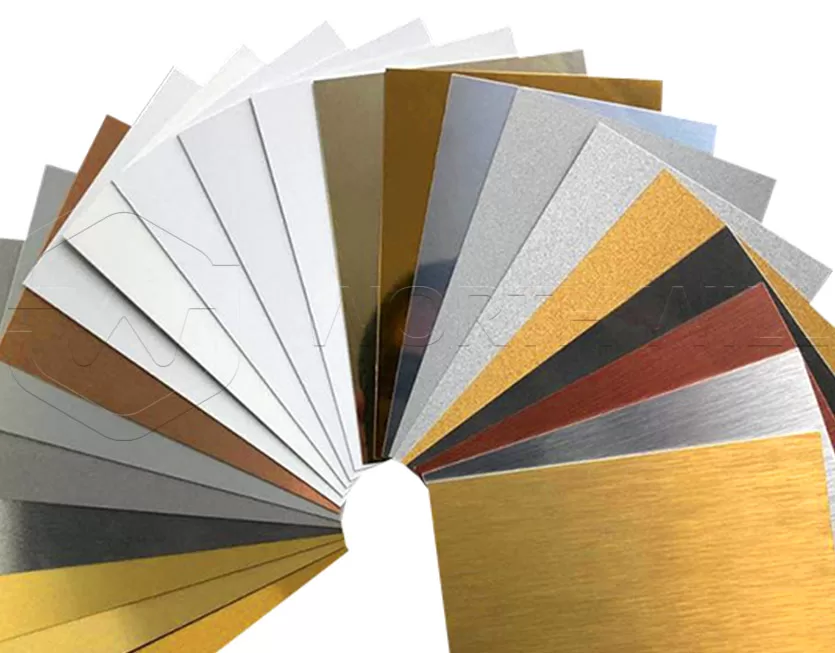

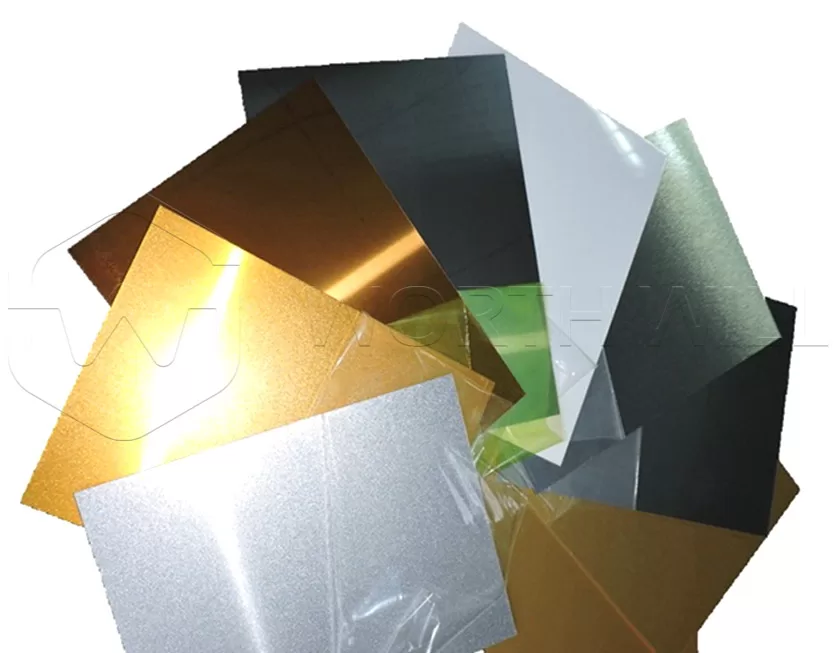

| Color | White, Gold, Silver or Customizable |

| Common width | 50-1250 mm |

| Common thickness | 0.25 mm, 0.45 mm, 0.65 mm, 1.0 mm (0.2-2.0 mm) |

| Common sheet size | 1200*600 mm, 600*400 mm, 600*300 mm and customized |

| Surface treatment | Glossy, matt, pearlized, polish finish, brushed |

| Quality | A grade for exportation |

(Note: Special specifications can be customized according to customer needs)

Advantage

- Bright and Long-lasting Color: Using dyed acrylic coating, the color is bright and long-lasting and not easy to fade.

- Wear resistance and corrosion resistance: The surface of the aluminum plate has been specially treated to have excellent wear resistance and corrosion resistance.

- Flat and smooth: The surface is flat and smooth, suitable for various printing and decoration treatments.

- Lightweight and easy to process: Aluminum material is lightweight and easy to process, making it easy to cut, bend, and process into various shapes.

- Eco-friendly: Aluminum is a recyclable material, contributing to sustainable practices and reducing environmental impact.

- Cost-effective: Compared to other materials, printed aluminum sheets offer a cost-effective solution for durable and visually appealing applications.

- Low maintenance: Their resistance to wear and tear requires minimal maintenance, saving time and resources in upkeep.

- High visibility: The vibrant colors and sharp details of printed designs make them highly visible, ideal for promotional and branding purposes.

- Fire-resistant: Aluminum has inherent fire-resistant properties, adding an extra layer of safety in various applications.

Application

- Automotive industry: automotive interior panels, body trim, etc.

- Interior decoration: wall decorative panels, ceilings, furniture surface decoration, etc.

- Packaging industry: gift boxes, wine bottle packaging, food packaging, etc.

- Advertising Displays: Businesses use them in advertising displays, including billboards, trade show booths, and promotional stands. These displays attract attention with eye-catching graphics.

- Furniture: Furniture designers incorporate printed aluminum sheets into tabletops, cabinet doors, and decorative accents. This addition adds modern flair to interior furnishings.

- Industrial Applications: They find use in various industrial applications such as equipment enclosures, machine covers, and control panels, providing both functionality and aesthetics.

- Art and Decorative Applications: Artists and designers create artworks, sculptures, and decorative installations using printed aluminum sheets. They choose this material for its versatility and visual impact.

- Electronics: Electronic products such as laptop covers, smartphone casings, and consumer electronics use them. These applications offer both protection and customization options.

What options are available?

For your photo print on metal, first choose between direct printing or laminated printing on Dibond aluminum. For direct printing, you can opt for a classic aluminum backing or brushed aluminum. The latter lends a shimmering effect to your design. For lamination, three branded papers are available or you can select an ultraHD print, which is perfect for photographs rich in detail. Furthermore, you can enhance your aluminum print with a custom-made frame. You will find a wide selection of frames to enhance colors of your metal print.

If you need dye sub aluminum sheet, send a message to us. Thank you!