Anodized aluminum panels are a popular choice across many industries, known for their outstanding durability, sleek appearance, and excellent resistance to corrosion. But what exactly are they, and why are they so widely used?

Specification

- Classification: Architectural panels, decorative panels, building cladding

- Thickness: 0.2mm – 6.0mm (customizable)

- Surface Finish: Anodized (matte, brushed, mirror)

- Alloy: 1100, 3003, 5005, 6061, etc.

Specifications

When considering anodized aluminum panels, several key specifications influence their performance and suitability for different projects.

- Classification: The anodizing process is classified into different types based on the electrolyte used and the resulting layer thickness and hardness:

- Type I (Chromic Anodize): Produces a thin, opaque, and corrosion-resistant layer. It’s excellent for precision parts and bonding applications.

- Type II (Sulfuric Anodize): The most common type, creating a thicker, clear, or colored layer. It offers good corrosion and abrasion resistance and is widely used for decorative and protective purposes.

- Type III (Hard Coat Anodize): Also known as hard anodizing or hard coat, this process produces the thickest, densest, and hardest layer. It provides superior wear resistance, making it suitable for high-wear applications like gears or military components.

- Thickness: The thickness of the anodic layer is crucial for performance. It’s measured in microns (µm). Thicker layers generally provide better corrosion and abrasion resistance. For architectural anodized aluminum panels, thicknesses often range from 10 to 25 microns for Type II and 25 to 60+ microns for Type III.

- Alloy: Not all aluminum alloys are created equal when it comes to anodizing. The choice of alloy significantly impacts the final appearance and consistency of the anodized finish. Alloys like 5005, 5052, 6061, and 6063 are common for anodizing due to their good response to the process and their suitability for various applications. For example, 5005 is excellent for decorative finishes, while 6061 offers good strength.

Benefits of Choosing Anodized Aluminum

The popularity of anodized aluminum panels stems from their numerous advantages:

- Exceptional Durability: The hard, oxide layer provides superior scratch and abrasion resistance compared to raw aluminum.

- Corrosion Resistance: The anodic layer acts as a barrier, protecting the underlying aluminum from oxidation and corrosion, especially in harsh environments.

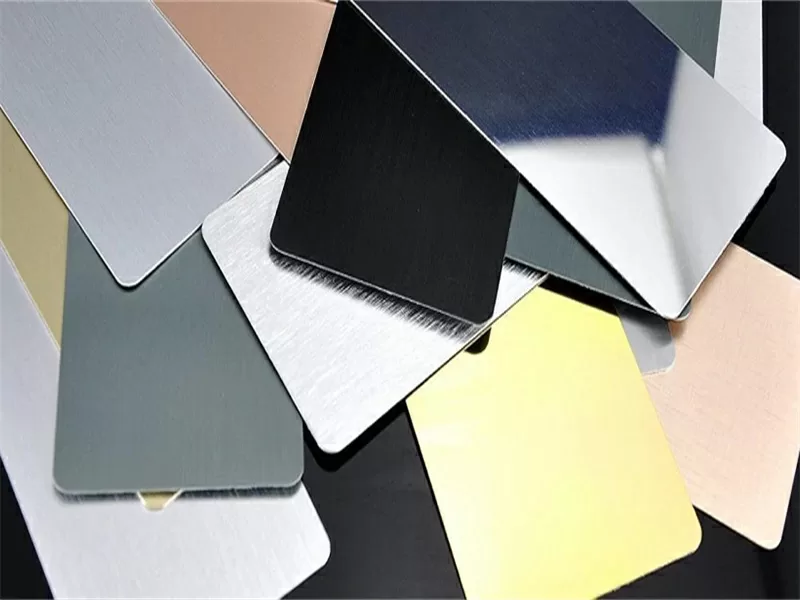

- Aesthetic Appeal: Anodizing can create a variety of attractive finishes, from clear metallic looks to vibrant colors (when dyed). It maintains the metallic sheen of aluminum.

- UV Stability: Unlike painted surfaces, the color in anodized aluminum is highly stable and resists fading from UV exposure, making it ideal for outdoor use.

- Low Maintenance: The smooth, hard surface is easy to clean and requires minimal upkeep.

- Environmentally Friendly: Anodizing is an environmentally responsible process, as it involves natural oxidation and produces fewer harmful byproducts compared to other finishes.

What are the Disadvantages of Anodized Aluminum?

While anodized aluminum offers many benefits, it also has some limitations:

- Cost: Anodizing adds to the cost of raw aluminum. While it’s often more affordable than painting or powder coating for long-term durability, the initial investment can be higher than untreated aluminum alloy.

- Limited Color Palette: Compared to painting, the range of colors available for anodized aluminum is more limited. Achieving very bright or specific custom colors can be challenging or impossible with anodizing.

- Inconsistent Finish: Due to variations in the aluminum alloy’s composition and the anodizing process itself, slight color and sheen variations can occur between different batches of anodized aluminum panels.

- Susceptibility to Etching: Strong acids or alkaline cleaners can damage the anodized layer, causing etching or staining. Care must be taken when cleaning anodized aluminum.

- Does Not Hide Imperfections: Anodizing is a transparent or translucent finish. Any scratches, dents, or surface imperfections on the raw aluminum sheet will be visible through the anodized layer. Surface preparation is critical.

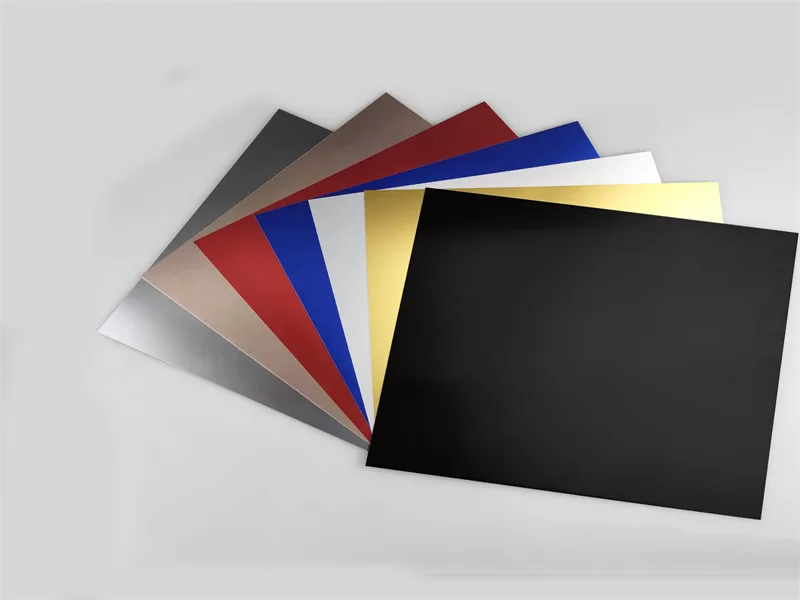

Types of Anodized Aluminum Panels

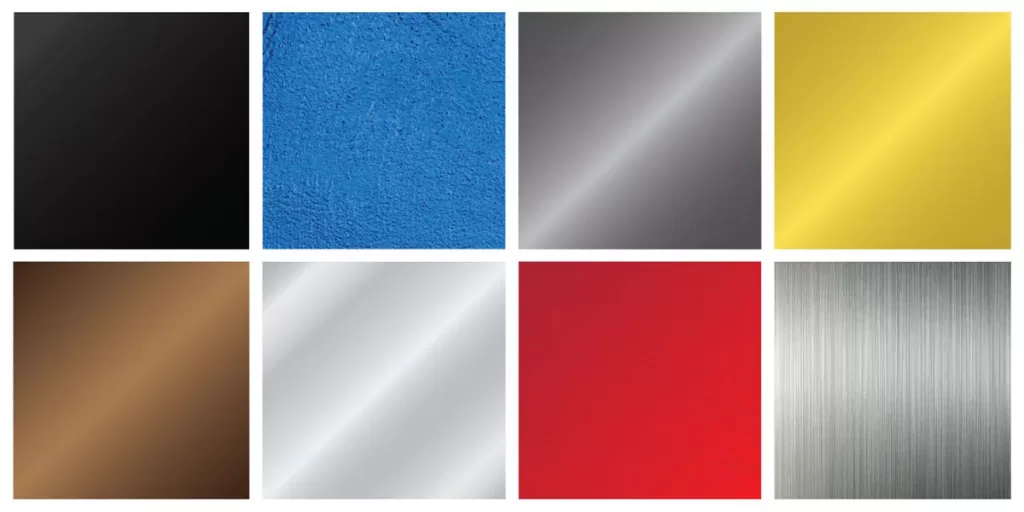

Anodized aluminum panels are available in various colors and finishes, making them ideal for both functional and decorative purposes. Below are some of the most popular types:

| Type | Color Finish | Key Features | Common Applications |

|---|---|---|---|

| Black Anodized Aluminum | Matte / Glossy Black | Modern look, UV resistant, scratch-proof | Facades, signage, electronics, luxury packaging |

| White Anodized Aluminum | Clean White | Minimalist, corrosion resistant, easy to clean | Interior panels, lighting fixtures, kitchen appliances |

| Blue Anodized Aluminum | Deep Blue / Vivid Blue | Eye-catching, decorative, durable finish | Branding elements, art pieces, custom electronics |

| Gold Anodized Aluminum | Gold Satin / Polished | Elegant, premium look, long-lasting sheen | Jewelry, nameplates, decorative hardware |

| Bronze Anodized Aluminum | Dark Bronze | Rich tone, architectural use, weather resistant | Doors, windows, curtain walls |

| Champagne Anodized | Light Gold / Neutral Beige | Soft metallic shine, subtle luxury feel | Interior décor, signage, trims |

| Custom Colors | Red, Green, Purple, etc. | Tailored to design needs, vibrant finishes, consistent coating | Brand identity, creative projects, high-end consumer goods |

Black Anodized Aluminum Panel

Black anodized aluminum is widely used for high-end architectural design, electronics, and interior decoration. Its sleek, matte or glossy black finish gives a modern and professional look. The black coating is UV stable, meaning it won’t fade easily outdoors.

Applications:

- Building facades

- Signage and displays

- Control panels and electronics

- Luxury packaging and labels

White Anodized Aluminum Panel

White anodized aluminum provides a clean and minimalistic appearance, commonly used in interior design, lighting fixtures, and kitchen equipment. It offers all the benefits of anodized aluminum—anti-corrosion, scratch resistance, and easy maintenance—with a neutral tone.

Applications:

- Wall panels and partitions

- Medical and laboratory equipment

- Home appliances

- Furniture accents

Blue Anodized Aluminum Panel

Blue anodized aluminum stands out in decorative applications and branding projects. Its vivid color offers a unique touch for signage, art installations, and consumer electronics. The blue anodized layer remains vibrant and does not peel or flake over time.

Applications:

- Decorative trims

- Jewelry and accessories

- Custom electronics casings

- Corporate signage

Custom Anodized Colors Available

At WORTHWILL ALUMINUM, we also offer custom anodized panels in colors like gold, bronze, champagne, and rose gold. Whether you need a subtle brushed texture or a polished mirror finish, we can tailor the aluminum surface to meet your specific design and application needs.

How Long Will Anodized Aluminum Last?

The lifespan of anodized aluminum is one of its strongest selling points. When properly maintained and used in suitable environments, anodized aluminum panels can last for decades.

- Indoor Applications: For interior use, such as decorative panels or appliance components, anodized aluminum can last indefinitely, often exceeding 50 years, with minimal degradation.

- Outdoor Applications: In exterior architectural applications, anodized aluminum typically maintains its appearance and protective qualities for 10 to 20 years or more, even in challenging climates. Factors like air pollution, salt spray (in coastal areas), and extreme UV exposure can influence its lifespan. Hard coat (Type III) anodizing provides the longest outdoor durability.

Is it Expensive to Anodize Aluminum?

The cost of anodizing aluminum panels varies depending on several factors: the size and complexity of the parts, the type of anodizing (Type I, II, or III), the desired layer thickness, and any additional finishing processes like dyeing.

Generally, anodizing is a cost-effective finishing solution in the long run, especially when considering its exceptional durability and low maintenance. While the initial cost is higher than that of raw aluminum, it often proves more economical over the product’s lifespan compared to alternatives that may require frequent recoating or replacement due to corrosion or wear. For high-volume projects, the per-unit cost of anodizing decreases significantly.

What is an Anodized Aluminum Sheet?

An anodized aluminum sheet refers to a flat piece of aluminum alloy that has undergone the anodization process. The terms “sheet” and “panel” are often used interchangeably to describe these flat forms of anodized metal. These sheets are widely available in various thicknesses, sizes, and finishes (clear, colored, brushed) and are then cut, formed, or fabricated into final products.

The surface of an anodized aluminum sheet is non-conductive, hard, and resistant to environmental factors, making it suitable for a vast array of applications, from wall cladding to consumer electronics.

Aluminum Alloy vs. Anodized Aluminum

It’s important to understand the difference between aluminum alloy and anodized aluminum:

| Feature | Aluminum Alloy | Anodized Aluminum |

|---|---|---|

| Surface Treatment | No or basic finish | Electrochemically treated |

| Corrosion Resistance | Medium | High |

| Aesthetic Variety | Limited | Wide (color, texture) |

| Cost | Lower | Slightly higher |

- Aluminum Alloy: This is the base metal. It’s lightweight, strong, and corrosion-resistant due to its natural oxide layer, but this layer is thin and can easily scratch or be degraded by certain chemicals. Raw aluminum alloy can also appear dull or oxidize over time, especially in outdoor environments.

- Anodized Aluminum: This is an aluminum alloy that has been treated with the anodization process. The anodizing process chemically enhances the natural oxide layer, making it significantly thicker, harder, and more protective. This enhanced layer provides superior corrosion resistance, abrasion resistance, and allows for various aesthetic finishes (like colors).

In essence, anodized aluminum is a stronger, more durable, and more aesthetically versatile version of the original aluminum alloy, specifically engineered for enhanced performance and appearance.

Common Applications of Anodized Aluminum Panels

The versatility and robust properties of anodized aluminum panels make them suitable for a wide range of applications:

- Architecture and Construction:

- Building facades and exterior cladding

- Roofing and canopies

- Interior wall panels and decorative elements

- Window frames and door trims

- Consumer Goods:

- Appliance exteriors (refrigerators, microwaves)

- Smartphones, laptops, and tablet casings

- Sporting equipment (bikes, camping gear)

- Automotive and Transportation:

- Interior and exterior trim

- Decorative components

- Signage:

- Durable outdoor and indoor signs

- Nameplates and labels

- Marine:

- Boat parts and components due to saltwater resistance

- Industrial and Manufacturing:

- Machine parts and enclosures

- Medical equipment components

- Cleanroom panels

What are Anodized Aluminum Panels?

At its core, anodized aluminum is an aluminum material that has undergone an electrochemical process called anodization. This process transforms the surface of the aluminum alloy into a robust, dense, and highly protective oxide layer. Unlike paint or plating, this layer is integrated into the metal itself, making it incredibly durable and resistant to chipping, peeling, or fading.

This special surface makes anodized aluminum panels ideal for both indoor and outdoor applications where aesthetics and long-term performance are crucial. From architectural facades to electronic casings, the unique properties of anodized aluminum make it a preferred material.

Frequently Asked Questions

What are the disadvantages of anodized aluminum?

- Limited color range compared to painted finishes

- Slightly higher cost than untreated aluminum

- Requires careful cleaning to avoid surface damage

How long will anodized aluminum last?

With proper maintenance, anodized aluminum can last 20–50 years in exterior applications. It does not peel or rust and resists UV damage.

Is it expensive to anodize aluminum?

Anodizing adds a small cost compared to raw aluminum, but it offers excellent value over time due to lower maintenance and extended life.

Why Choose Worthwill Aluminum?

WORTHWILL ALUMINUM offers high-quality anodized aluminum panels in custom sizes, thicknesses, and colors. With factory-direct prices, professional service, and strict quality control, we are your trusted partner for aluminum products in construction, design, and industrial applications.

Contact Us for Anodized Aluminum Panels

Looking for premium anodized aluminum sheets or panels?

📩 Email: jane@wwaluminum.com

📱 WhatsApp: +8615736973771

🌍 Website: www.wwaluminum.com