Aluminum Mirror

The coated mirror aluminum is made up of many ways, such as rolling and polishing, to make the surface like a mirror. There are many kinds of color in the mirror finish aluminum. Welcome to get more details from our company.

| Product: | Mirror Aluminum |

| Color Chart: | Black, white, red, mirror silver, mirror gold, etc. |

| Alloy : | 1050, 3003, etc. |

| Temper: | H18/H14/H24, etc. |

| Width: | 30-1750mm (or as per requirments) |

| Delivery: | Within 30 days |

| MOQ: | 2-4 tons |

- Light weight

- High strength

- Good flatness

- Bright color

- Easy clean

- Good ductility

- Good maintain

It’s widely used in the fields of lighting, cosmetic box, handicraft, advertisement light word, electric appliance panel, mobile electronic appliance panel, mobile electronic equipment and so on. We can see the applications of mirror aluminum every where.

Types

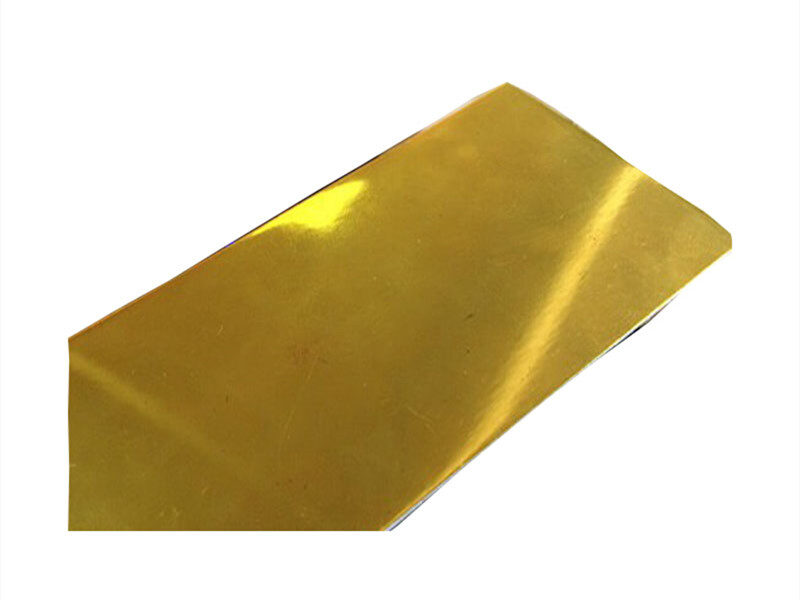

Coated aluminum mirror

- Mirror silver aluminium generally no coated, the reflectivity of it is about 85% – 90%

- Gold, light gold, tea gold, black coating 12-14 microns, all of these of the reflectivity about 80%.

Attention: After the mirror surface aluminum coil is pulled back, it doesn’t need to be cleaned, and it is directly coated. Cleaning will affect the surface.

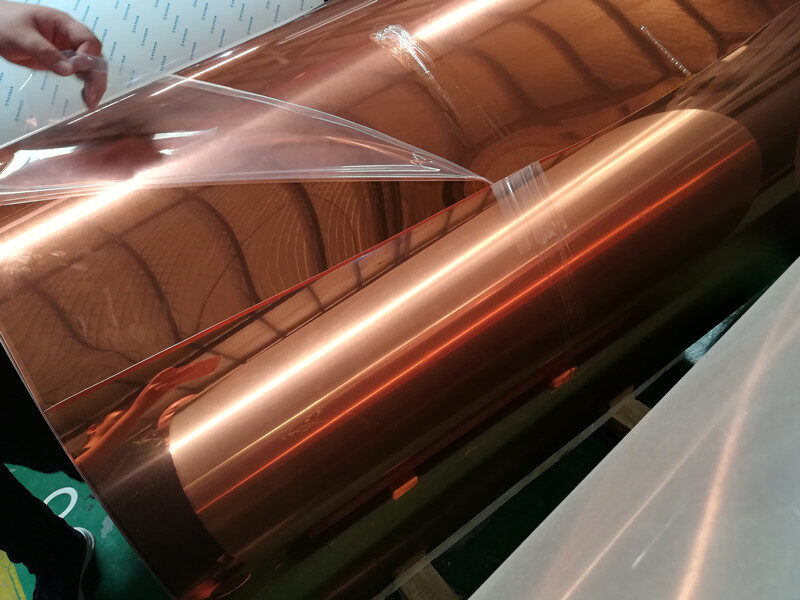

Film coated mirror aluminum

Common film colors are blue and yellow, both low to medium viscosity.

Polishing aluminium to a mirror finish

The most is use an aluminum alloy mirror polisher. Our factory has advanced polishing machinery and equipment. We wholesale mirror polished aluminium sheet and coil. And our foreign all have a good feedback about our mirror aluminum products.

Mirror polished aluminium sheet factories

Our company is the national sales company of Henan Jinyu Color Aluminum Co.,Ltd. Our factory is located in the industrial park. We have professional technical staff, many experience of produce aluminum products. Our company also has many honor certificate. We are the only one who can produce thickness 5.0mm and width 1800mm roller coated products in our province.

Mirror surface aluminum sheet

Generally speaking, mirror aluminium sheet is more common use than coil. Mirror aluminum plate is just a general term. According to the high, medium and low mirror surface of the plate, it can be divided into standard mirror, high mirror and super mirror. It’s a kind of material that the aluminum veneer has been mirror treated. Mirror surface aluminium coil is formed by aluminium coil. Due to the different demands, any shapes and colors we can do it.

Aluminum mirror sheet price list

Our products are made up of the raw material aluminum. It has a competitive price in the nation market. So if you want to build up business cooperation with us ,we will give you the best price on the premise of the quality.

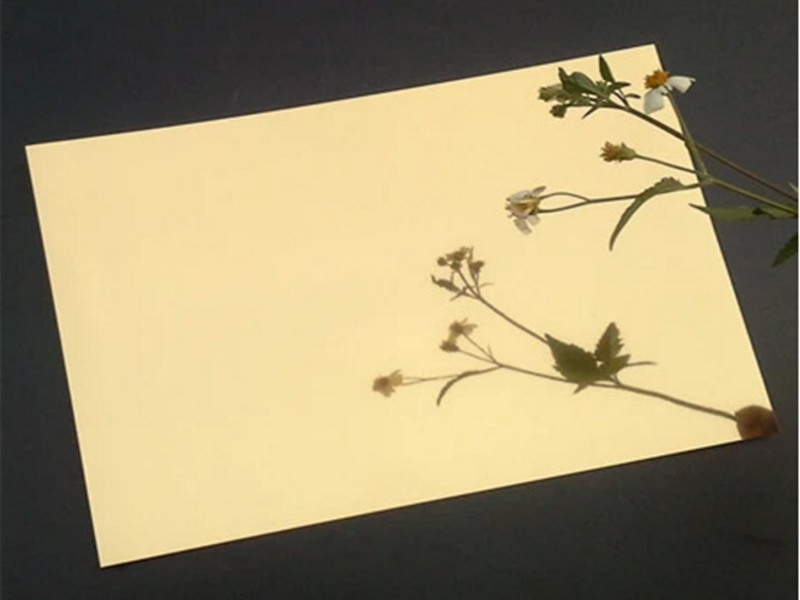

Colors

There are many colors about the products, such as mirror gold aluminium, light gold, silver, tea gold, black these common mirror colors. Also other colors we can do it.

Specification

Item: mirror surface aluminum coil and aluminum sheet

Alloy: 1050/1060/1100/3003 etc.

Temper: H24/H14/H18 etc.

Thickness: as per customer’s requests

Size:0.25-1.35mm x 30-1350mm

Capacity:500 Tons/month

Mirror aluminum market development

Due to the great feedback, our company begin to develop and expand the market. The aluminium mirror plate products has spread to UAE, Brazil, Syria, Iran, Indonesia.

Worthwill will take more measures to widely spread our products and insist on being an excellent supplier in the hearts of customers.

Polish

Polishing refers to the use of mechanical, chemical or electrochemical action to reduce the surface roughness of the work piece to obtain a bright and smooth surface.

It is the modification processing of the work piece surface using polishing tools and abrasive particles or other polishing media.

China aluminium composite mirror sheet

Mirror aluminium composite panel is a combination of modern fine technology, polishing the surface aluminium substrate, like a mirror.

Then use high-quality domestic high-transparency paint such as gold, silver, brown and so on. Our company use the famous paint brand PPG/BECKER.

Surface

The surface is coated with paint and combined with the core board to form a high-end and fashionable decorative material.

The construction performance of this type of product is the same as that of common aluminium-plastic composite panel materials, and it can bent and fold.

The production process of the mirror aluminum

- Aluminum plate is the raw material.

- After pre-cleaning and pre-processing the aluminium plate

- Polish surface

- Electroplated or painted with transparent UV coloring

- Film coated

Aluminum mirror exporter

Our company is a private Joint-stock Company, registered capital by 50,000,000, CNY, covers an area of 80,000 square meters with more than 30 technical and management personnel.

We are led by technological innovation, integrated on Scientific Research, Marketing and Production, supported by Henan Provincial Commerce Department as an Export-Oriented enterprise.

The distinguish of the mirror glass and mirror aluminum

Silver mirror is one of the glass mirror. The exterior of mirror glass and mirror aluminium are very similar but they also have some different aspects.

- Silver mirror is made of silver electroplating, aluminium mirror is made of metal aluminium

- The price of silver type is higher than the mirror aluminium

- Under the same light intensity, silver type will appear brighter.

Where to use the aluminum mirror?

Nowadays, it’s indispensable with mirror elements in the design of architectural landscape visual effects. The mirror uses special materials to allow the building and space to communicate face-to-face.The reflection and mirroring create a magical space effect and form a unique space experience.

We can see the mirror aluminium every where in our life. Large to architecture, small to decoration. Due to the need of people’s daily life, and the development of technology, mirror surface aluminium have a bright future.

How to clean the surface of the mirror finish aluminum?

- Rinse the board surface with a lot of water

- Use a soft cloth soaked in detergent diluted with water to gently wipe the board surface

- Rinse the board surface with a lot of water to wash away the dirt

- Use detergent to clean the no clean place

- Rinse the board with clean water until all the detergent away.