What is HD Aluminum Sublimation Sheet?

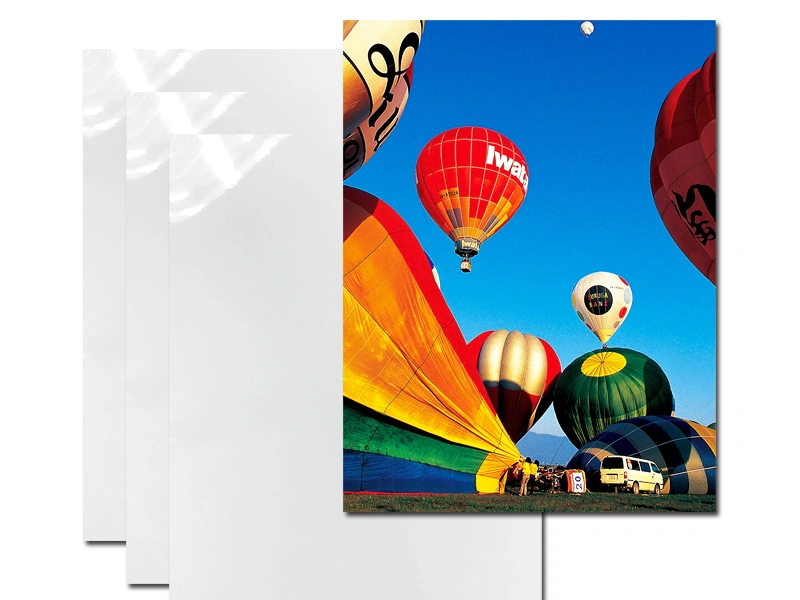

HD Aluminum Sublimation Sheet is a premium substrate specifically engineered for high-definition sublimation printing. Featuring an ultra-smooth, specially coated surface, these sheets deliver exceptional image clarity, vibrant color reproduction, and professional-grade results for demanding printing applications.

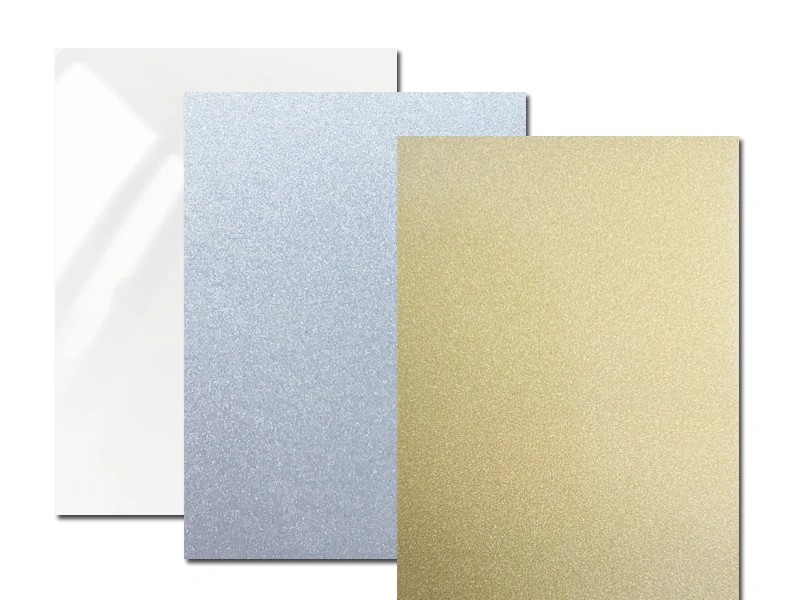

Classification of HD Aluminum Sublimation Sheets

| Type | Surface Finish | Resolution Support | Best For |

|---|---|---|---|

| Glossy HD | High-gloss reflective | Up to 1440 dpi | Photography, product displays |

| Matte HD | Non-reflective smooth | Up to 1440 dpi | Art reproductions, gallery prints |

| Metallic HD | Pearlized effect | Up to 1200 dpi | Premium signage, luxury items |

| Textured HD | Embossed patterns | Up to 1200 dpi | Special effects, decorative applications |

Thickness Options and Specifications

| Thickness (mm) | Weight (g/m²) | Rigidity Level | Recommended Applications |

|---|---|---|---|

| 0.8 | 216 | Flexible | Photo panels, small signage |

| 1.0 | 270 | Medium | Retail displays, menu boards |

| 1.5 | 405 | High | Exhibition graphics, partitions |

| 2.0 | 540 | Very High | Architectural elements, durable signs |

| 3.0 | 810 | Maximum | Heavy-duty applications, large formats |

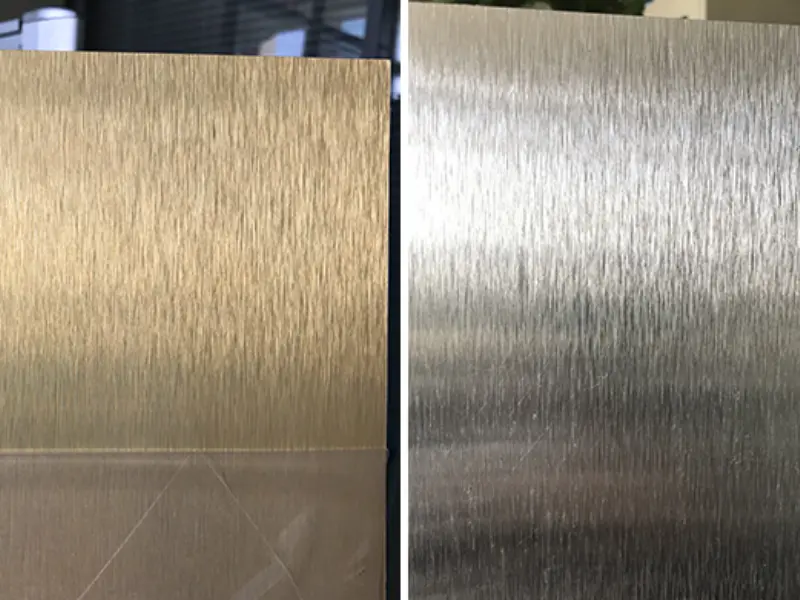

Aluminum Alloy Options

| Alloy | Properties | Best For |

|---|---|---|

| 1050 | Excellent flatness | High-precision printing |

| 3003 | Good strength, formability | General purpose applications |

| 5005 | Superior corrosion resistance | Outdoor applications, high humidity |

| 6061 | Structural strength | Large format displays, heavy usage |

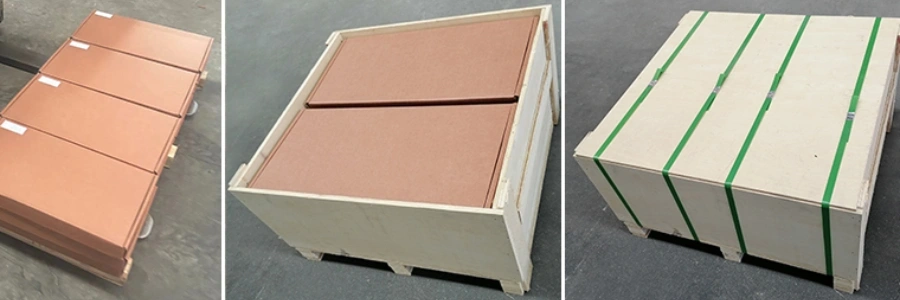

Packaging and Handling

Professional packaging ensures perfect condition:

- Individual Protection: PE film on both sides

- Interleaving: Foam separators between sheets

- Edge Protection: Reinforced corner guards

- Weather Proofing: Waterproof outer wrapping

- Custom Packaging: Available for specific needs

Standard packaging quantities:

- 25 sheets/box (0.8-1.0mm)

- 20 sheets/box (1.5mm)

- 15 sheets/box (2.0mm)

- 10 sheets/box (3.0mm)

Key Features and Benefits

✅ Ultra-High Definition: Supports up to 1440 dpi resolution

✅ Excellent Color Reproduction: Vibrant, accurate colors

✅ Superior Smoothness: Ra ≤0.1μm surface roughness

✅ Quick Drying: Optimized coating for fast ink absorption

✅ Scratch Resistance: Durable surface handling

✅ Wide Color Gamut: 95%+ Adobe RGB coverage

✅ Environmentally Friendly: Recyclable aluminum base

Technical Specifications

| Parameter | Specification | Testing Standard |

|---|---|---|

| Surface Smoothness | Ra ≤0.1μm | ISO 4287 |

| Whiteness Degree | 95-98% | ISO 11475 |

| Color Gamut | ≥95% Adobe RGB | ISO 12640-2 |

| Ink Absorption | ≤2 seconds | Industry standard |

| Sublimation Temperature | 180-200°C | – |

Applications

- Photography & Art:

- Professional photo prints

- Gallery artwork reproductions

- Limited edition prints

- Portfolio presentations

- Retail & Advertising:

- Point-of-sale displays

- Product presentation panels

- Trade show graphics

- Premium signage

- Interior Design:

- Wall art and decor

- Office decoration

- Hotel and restaurant graphics

- Custom interior elements

- Industrial Applications:

- Control panel overlays

- Machine identification plates

- Safety signage

- Equipment branding

- Specialty Applications:

- Awards and trophies

- Personalized gifts

- Exhibition displays

- Architectural features

Printing Guidelines

Optimal Printing Parameters:

- Resolution: 600-1440 dpi

- Color Mode: CMYK with ICC profiles

- Ink Type: Sublimation ink only

- Drying Time: 10-15 minutes after printing

Heat Press Settings:

- Temperature: 185-195°C

- Time: 45-60 seconds

- Pressure: Medium (0.5-1.0 kg/cm²)

- Cooling: Natural cooling before handling

Quality Assurance

Rigorous Testing Includes:

- Surface smoothness verification

- Coating uniformity

- Whiteness consistency

- Ink absorption testing

- Color reproduction accuracy

- Packaging integrity

Comparison with Standard Sublimation Sheets

| Feature | HD Sheets | Standard Sheets | Improvement |

|---|---|---|---|

| Resolution | Up to 1440 dpi | Up to 720 dpi | 2x |

| Color Accuracy | ±2% Delta E | ±5% Delta E | 2.5x |

| Surface Smoothness | Ra ≤0.1μm | Ra ≤0.3μm | 3x |

| Ink Absorption | ≤2 seconds | ≤5 seconds | 2.5x |

Maintenance and Care

Handling Instructions:

- Store in dry, flat conditions

- Handle with clean gloves

- Avoid surface scratching

- Keep protective film until use

Cleaning Recommendations:

- Use soft microfiber cloth

- Mild detergent if necessary

- Avoid abrasive cleaners

- Dry immediately after cleaning

FAQ

Q: What makes HD sheets different from regular sublimation sheets?

A: HD sheets feature ultra-smooth surfaces and specialized coatings that support higher resolutions and better color reproduction.

Q: Can HD sheets be used outdoors?

A: Yes, especially when using alloys like 5005 with appropriate protective coatings.

Q: What is the minimum order quantity?

A: Typically 25 sheets for standard sizes, but varies by manufacturer.

Q: How long do HD sublimation prints last?

A: 5-8 years indoors with proper care and handling.

Q: Are custom sizes available?

A: Yes, most manufacturers offer custom cutting services.

Why Choose HD Sublimation Aluminum Sheets?

The decision to choose an HD sublimation aluminum sheet over a standard sublimation blank is driven by a commitment to superior quality and an desire for truly exceptional results in your metal printing projects.

- Unrivaled Image Clarity: For critical applications like professional photography or fine art reproduction, the “HD” quality means every detail, texture, and nuance is rendered with incredible precision.

- Premium Presentation: HD metal prints possess a visual depth and vibrancy that immediately conveys a high-end, gallery-quality aesthetic, elevating the perceived value of any image.

- Lasting Impression: The combination of vivid, durable prints on a sleek aluminum surface creates a modern and impactful statement that stands the test of time, resistant to environmental factors that degrade other print types.

- Differentiation: In a competitive market, offering HD sublimation aluminum sheets allows you to produce products that genuinely stand out, capturing attention and reflecting a commitment to excellence.

- Versatility for High-Impact Visuals: Ideal for designs where color accuracy, sharpness, and dynamic range are paramount, from striking graphics to intricate photographic compositions.

For those who demand the absolute best in visual fidelity and durability, the HD sublimation aluminum sheet is the definitive choice for creating stunning and lasting custom metal prints.

Tips for Successful HD Sublimation Printing on Aluminum

Achieving the best results with your HD sublimation aluminum sheet requires attention to detail throughout the printing and pressing process.

- Mirror Your Image: Always remember to print your design in a mirror image (reversed) as it will flip back to the correct orientation during heat transfer.

- Remove Protective Film: This is critical! Carefully peel off the clear plastic protective film from the coated side of the aluminum sheet just before pressing.

- Precise Time, Temperature, and Pressure: Adhere strictly to the manufacturer’s recommended settings for your specific HD sublimation aluminum sheet and heat press model. These settings are crucial for optimal ink transfer and color development.

- Use Protective Paper: Place a sheet of butcher paper (or non-stick parchment paper) above and below your aluminum sheet and transfer. This prevents ink bleed-through onto your heat press platens and helps avoid “ghosting.”

- Ensure Impeccable Cleanliness: Make sure your HD sublimation aluminum sheet, transfer paper, and heat press are completely free from dust, lint, or debris, as even tiny particles can cause noticeable imperfections in the final HD print.

- Even Pressure Distribution: Apply firm and consistent pressure across the entire surface of the aluminum sheet during pressing to ensure a uniform and complete transfer of ink.

- Proper Cooling: Allow the sublimated sheet to cool completely before handling or removing it from the press. The coating can be delicate when hot.

Following these tips will help you consistently produce stunning, high-definition metal prints with your HD sublimation aluminum sheets.

Conclusion

HD Aluminum Sublimation Sheet represent the pinnacle of sublimation printing technology, offering unparalleled image quality and color performance. Their ultra-smooth surfaces and advanced coatings make them the ideal choice for applications where image quality is paramount.

The key advantages include:

- Exceptional image clarity and detail

- Vibrant, accurate color reproduction

- Superior surface smoothness

- Excellent durability and scratch resistance

- Wide range of applications

Specifications and Types of HD Aluminum Sublimation Sheet

Here is a comprehensive overview of common specifications and types for HD sublimation aluminum sheets, presented in a clear table format to highlight their digital and physical characteristics.

| Feature | Description | Common Specifications | Key Characteristics & Applications |

|---|---|---|---|

| Material | High-grade aluminum alloy base, specially processed for sublimation. | Alloys: 5005, 6061 (optimized for HD coating adhesion) | Ensures a flat, stable, and durable base for HD prints. |

| Coating | Advanced polymer coating engineered for maximum ink absorption and clarity. | Finish: Gloss White HD, Matte White HD, Satin White HD | Gloss: Vibrant, high contrast. Matte/Satin: Reduced glare, sophisticated look. All offer HD clarity. |

| Thickness | Gauge of the aluminum sheet, impacting rigidity and weight. | 0.5 mm (0.02 in): Lightweight, moderate flexibility. | Best for lightweight décor, small, less rigid HD photo panels. |

| 0.7 mm (0.028 in): Standard, balanced durability and weight. | Most popular for HD photo prints, awards, medium signs. | ||

| 1.1 mm (0.043 in): Heavy-duty, maximum rigidity. | Large, prestigious awards, robust HD signage, large art pieces. | ||

| Sizes | Available dimensions, from small personal items to large displays. | Small: 4″x6″, 5″x7″, 8″x10″ (for HD photos, small gifts) | Personalized HD metal prints, desk art, ornaments. |

| Medium: 8.5″x11″, 11″x14″, 12″x18″ (for larger HD prints) | Standard wall art, office decor, mid-sized HD signage. | ||

| Large: 16″x20″, 20″x24″, 24″x36″ (and larger custom cuts) | Gallery art, large exhibition displays, commercial HD signage. | ||

| Protection | Essential layers to safeguard the blank before printing. | Film: Clear, single-sided, peel-off protective film. | Crucial for preventing scratches and dust on the HD coating. |

| Packaging | Methods used to secure and protect blanks during transit. | Interleaving Paper/Foam: Between sheets. Sturdy Cartons: Cardboard. | Ensures HD sublimation aluminum sheets arrive in flawless condition. |

These detailed specifications allow you to select the perfect HD sublimation aluminum sheet for any project, ensuring exceptional high-definition metal prints every time.