Pearl white aluminum sublimation offers just that: a unique blend of durability, vibrant color, and an elegant, shimmering finish that transforms ordinary images into breathtaking works of art. If you’re looking to create stunning, long-lasting metal prints with a premium touch, understanding the power of pearl white aluminum sublimation is your first step.

Classification of Pearl White Aluminum Sublimation Blanks

Pearl white aluminum sublimation blanks are available in various forms, primarily classified by their shape and intended use. This versatility allows for a wide range of creative projects.

- Flat Panels: These are the most common type, ranging from small photo prints to large wall art and signage. They provide a smooth, consistent surface for your designs.

- Pre-Cut Shapes: Manufacturers offer aluminum blanks in various pre-cut shapes, such as circles, ovals, hearts, and custom designs for ornaments, keychains, and small decorative items.

- Rolls/Large Sheets: For industrial or large-scale production, pearl white aluminum sublimation material can be purchased in larger sheets or rolls, which are then cut to size by the user.

Thickness Matters: Choosing Your Pearl White Aluminum Sublimation Blanks

The thickness of your pearl white aluminum sublimation blank significantly impacts its rigidity, weight, and overall feel. Selecting the correct thickness is crucial for the intended application and the desired quality of your metal prints.

- 0.5 mm (0.02 inches): This is the thinnest available, offering some flexibility.

- 0.7 mm (0.028 inches): This is a popular and versatile general-purpose thickness.

- 1.1 mm (0.043 inches) and above: These thicker blanks offer maximum rigidity and a premium, substantial feel. They are ideal for larger signs, awards, and any application where a robust, high-quality display is paramount.

Key Features

- Unique Pearlescent Sheen: The most distinct feature, adding a luxurious and dynamic shimmer to your images.

- Exceptional Color Reproduction: The bright white base combined with the specialized coating allows for incredibly vivid, true-to-life colors and sharp details.

- High Durability & Longevity: Sublimated images are embedded into the coating, making them highly resistant to scratches, moisture, and UV light, ensuring long-lasting beauty.

- Modern & Premium Aesthetic: Elevates any design, offering a sophisticated and contemporary look that is highly desirable.

- Lightweight Yet Robust: Aluminum is a strong yet relatively light material, making finished prints easy to handle and hang.

- Easy to Clean: The smooth, durable surface can be easily wiped clean without damaging the image.

These features make pearl white aluminum sublimation an excellent choice for anyone seeking to produce professional, high-impact metal prints.

Alloy: The Foundation of Quality Pearl White Aluminum Sublimation

- 1100 Series Aluminum Alloy: Known for its high purity and excellent formability.

- 3003 Series Aluminum Alloy: A stronger alloy than the 1100 series, offering good workability and corrosion resistance. It’s a common choice for general-purpose aluminum products.

- 5005 Series Aluminum Alloy: This is a very popular choice for sublimation blanks.

- 6061 Series Aluminum Alloy: A high-strength alloy often used in structural applications.

The right alloy ensures that the pearl white aluminum sublimation blank provides a perfectly flat and stable foundation for your exquisite custom metal prints.

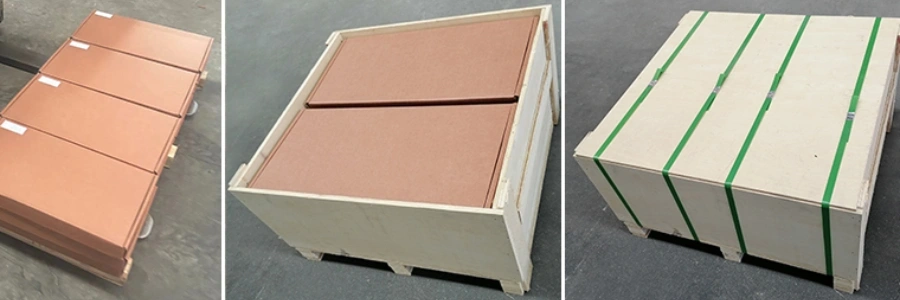

Packaging for Pearl White Aluminum Sublimation Blanks

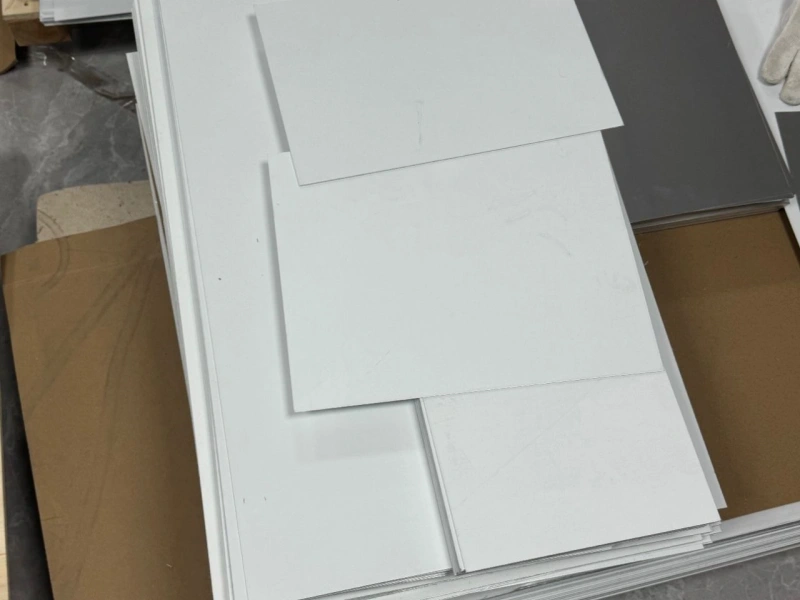

Proper packaging is absolutely vital for pearl white aluminum sublimation blanks. The specialized coating is sensitive to scratches and abrasions, so meticulous packaging ensures that the blanks arrive in pristine condition, ready for the sublimation printing process.

- Protective Film: Each blank typically comes with a clear, thin plastic film on the side to be sublimated. This film acts as a crucial barrier against scratches and dust during shipping and handling. It must be carefully peeled off before pressing.

- Interleaving Paper: Individual sheets are often separated by a soft, non-abrasive paper or foam sheet. This prevents direct contact between the coated surfaces, further safeguarding against scratches.

- Sturdy Cartons: Multiple blanks are securely packed into durable cardboard boxes designed to withstand the rigors of transit.

- Edge and Corner Protectors: For larger or heavier blanks, additional foam or plastic protectors may be added to corners and edges to prevent bending or chipping.

Why Choose Pearl White Aluminum Sublimation?

- Elevated Aesthetic: The pearlescent finish immediately adds a touch of luxury and sophistication to any design, making it look more expensive and unique.

- High-End Appeal: Ideal for premium gifts, awards, and artistic reproductions where a standard finish simply won’t suffice.

- Photographic Excellence: The brilliant white base and shimmering coating are perfect for showcasing high-resolution photographs, bringing out incredible detail and color depth.

- Durable Art: Combines the beauty of art with the resilience of metal, creating pieces that can last for generations.

- Versatile Design Compatibility: While adding a unique touch, the pearl white finish remains neutral enough to complement a vast array of colors and designs.

For those aiming to create truly memorable and visually striking metal prints, pearl white aluminum sublimation is an unparalleled choice.

Applications of Pearl White Aluminum Sublimation

The versatility and premium finish of pearl white aluminum sublimation make it suitable for a diverse range of applications, appealing to both personal and commercial markets.

- Personalized Photo Panels: Display family portraits, wedding photos, or travel memories with a brilliant, artistic flair.

- Fine Art Reproductions: Create museum-quality prints of paintings, illustrations, or digital art with added depth and shimmer.

- Corporate Awards & Plaques: Design elegant and durable awards for employee recognition, corporate milestones, or special achievements.

- Indoor & Outdoor Signage: Produce sophisticated and weather-resistant signs for businesses, galleries, or homes (ensure the coating is rated for outdoor use if applicable).

- Decorative Wall Art: Modern and sleek pieces for home decor, adding a contemporary touch to any room.

- Memorials & Tributes: Craft beautiful and lasting tributes for loved ones or significant events.

- Event & Exhibition Displays: Create professional and eye-catching display panels for trade shows, galleries, or public installations.

- Retail Product Displays: Enhance the presentation of high-value products with premium, custom-branded displays.

Each of these uses benefits from the unique qualities of pearl white aluminum sublimation, allowing for stunning and durable custom metal prints.

Tips for Successful Pearl White Aluminum Sublimation

To achieve the best possible results with your pearl white aluminum sublimation blanks, follow these essential tips:

- Mirror Your Image: Always print your design in a mirror image (reversed) as it will flip back to the correct orientation during the heat transfer process.

- Remove Protective Film: Before pressing, carefully peel off the clear plastic protective film from the coated side of the aluminum blank. Forgetting this step will result in a failed transfer.

- Correct Settings: Adhere strictly to the manufacturer’s recommended time, temperature, and pressure settings for your specific aluminum sublimation blank and heat press. These can vary.

- Use Protective Paper: Place a sheet of butcher paper or non-stick parchment paper above and below your blank and transfer. This prevents excess ink from staining your heat press platen and helps prevent “ghosting.”

- Ensure Cleanliness: Make sure your blank, transfer paper, and heat press are free from dust, lint, or debris, which can cause imperfections in your finished print.

- Even Pressure: Apply firm and even pressure across the entire surface of the blank to ensure a consistent and complete transfer of ink.

- Cool Properly: Allow the sublimated blank to cool completely before handling or removing it from the press, as the coating can be delicate when hot.

Following these tips will help you consistently produce beautiful, high-quality pearl white aluminum sublimation prints.

Sublimation Printing on Pear Sheets

Achieving the best results with your pearlized white sublimation sheet requires attention to detail.

- Print Mirror Image: Always remember to print your design in a mirror image, as it will flip during transfer.

- Remove Protective Film: Ensure you peel off the clear plastic film from the sheet before pressing.

- Correct Temperature and Time: Follow the manufacturer’s recommended settings for temperature and pressing time specific to the sublimation sheet and heat press.

- Even Pressure: Apply consistent and even pressure across the entire sheet for a uniform transfer.

- Cleanliness is Key: Ensure both your sheet and design are free from dust and debris to prevent imperfections.

- Use Butcher Paper: Place butcher paper above and below your sheet to prevent ink bleed-through onto your heat press.

Following these tips will help you create beautiful and lasting sublimation printing results.

Specifications and Types of Pearl White Aluminum Sublimation Sheets

To further clarify, here is a breakdown of common specifications and types you might encounter for pearl white aluminum sublimation blanks.

| Feature | Description | Common Specifications | Ideal Applications |

|---|---|---|---|

| Material | High-grade aluminum sheet specifically prepared for sublimation. | Alloys: 5005, 6061 (most common for blanks) | Ensures flat, durable, and receptive surface for prints. |

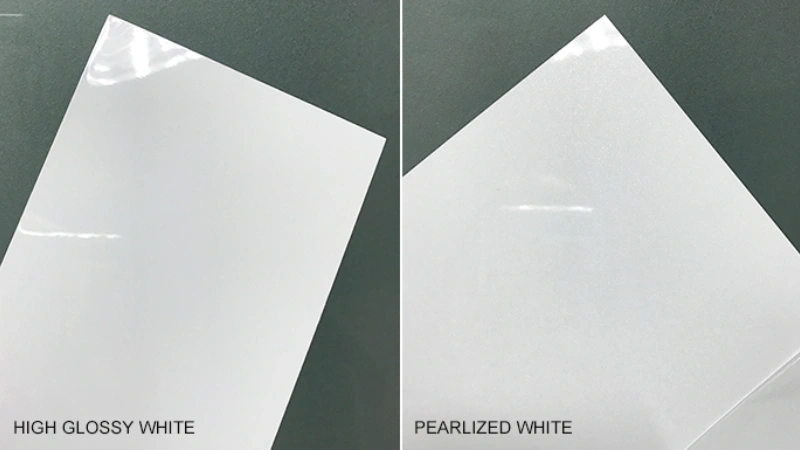

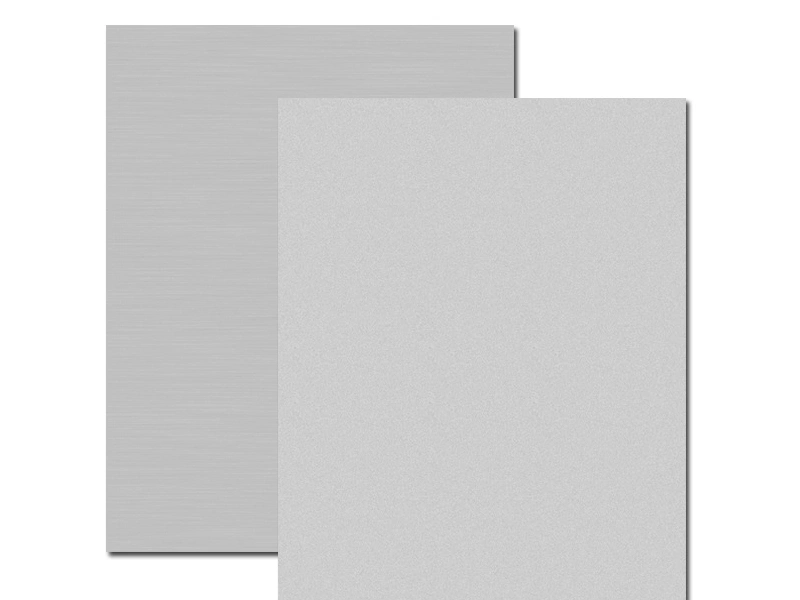

| Coating | Specialized polyester-based coating, infused with a pearlescent effect. | Finish: High-Gloss Pearl White, sometimes Semi-Gloss Pearl White | Adds a unique shimmer, vibrant color, and protection to images. |

| Thickness | The gauge of the aluminum, impacting rigidity and weight. | 0.5 mm (0.02 in): Lightweight, moderate flexibility. | Small crafts, flexible displays, very thin photo panels. |

| 0.7 mm (0.028 in): Standard, balanced durability and weight. | Most photo panels, small to medium signs, gifts, general awards. | ||

| 1.1 mm (0.043 in): Heavy-duty, maximum rigidity. | Large, premium awards, robust signs, substantial displays. | ||

| Sizes | Available dimensions, varying from small to very large format. | Small: 4″x6″, 5″x7″, 8″x10″ | Personalized photos, small gifts, ornaments, jewelry. |

| Medium: 8.5″x11″, 11″x14″, 12″x18″ | Standard-sized photo prints, medium wall art, office decor. | ||

| Large: 16″x20″, 20″x24″, 24″x36″ (and larger custom cuts) | Large wall art, exhibition displays, significant signage. | ||

| Protective | Essential layers to safeguard the blank before printing. | Film: Clear, single-sided, peel-off protective film. | Prevents scratches and dust on the printable surface. |

| Packaging | Methods used to secure and protect blanks during transport. | Interleaving Paper/Foam: Between sheets. Sturdy Cartons: Cardboard. | Guarantees blanks arrive in perfect condition, ready to use. |

These detailed specifications empower you to select the ideal pearl white aluminum sublimation blank for any project, ensuring exceptional custom metal prints every time.

What is Pearl White Aluminum Sublimation?

Pearl white aluminum sublimation refers to the process of transferring a high-resolution image onto a specially coated aluminum sheet.

The “pearl white” aspect is key. This finish enhances colors, adds depth, and provides a sophisticated look that standard white or matte finishes cannot replicate.