A brushed aluminum sublimation sheet is a popular material for personalized printing. With its brushed surface, it gives a unique metallic look while keeping strong durability. These sheets are widely used in signage, decoration, nameplates, and promotional products. This page explains classification, thickness, alloy, and packaging of brushed sublimation sheets, with details to help buyers choose the right option.

Classification of Brushed Sublimation Sheet

Brushed sublimation sheets can be classified by surface finish, coating, and size.

| Classification Type | Details |

|---|---|

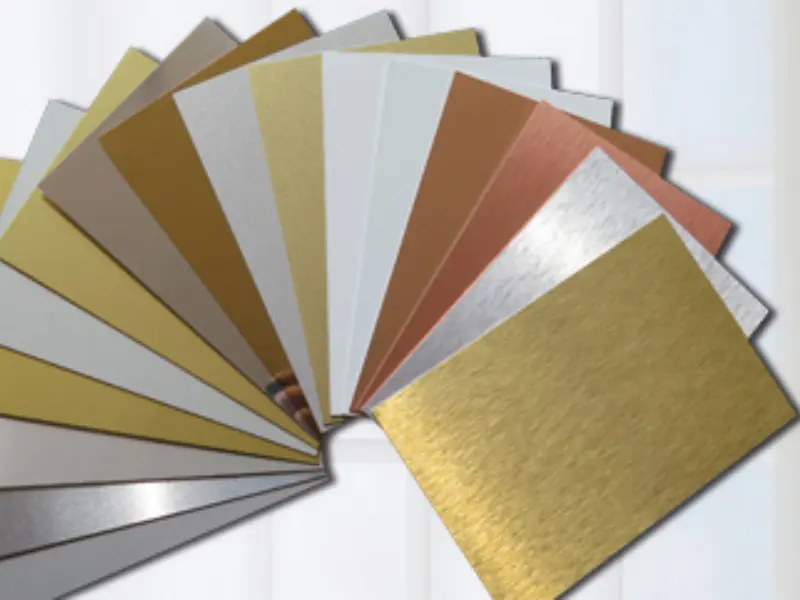

| Surface Finish | Brushed silver, brushed gold, brushed copper |

| Coating Type | Clear sublimation coating, matte coating, glossy coating |

| Sizes Available | A4, A3, 12″x24″, custom cut-to-size |

| Printing Compatibility | Inkjet sublimation ink, heat transfer sublimation |

specific coating.

- Finish Type:

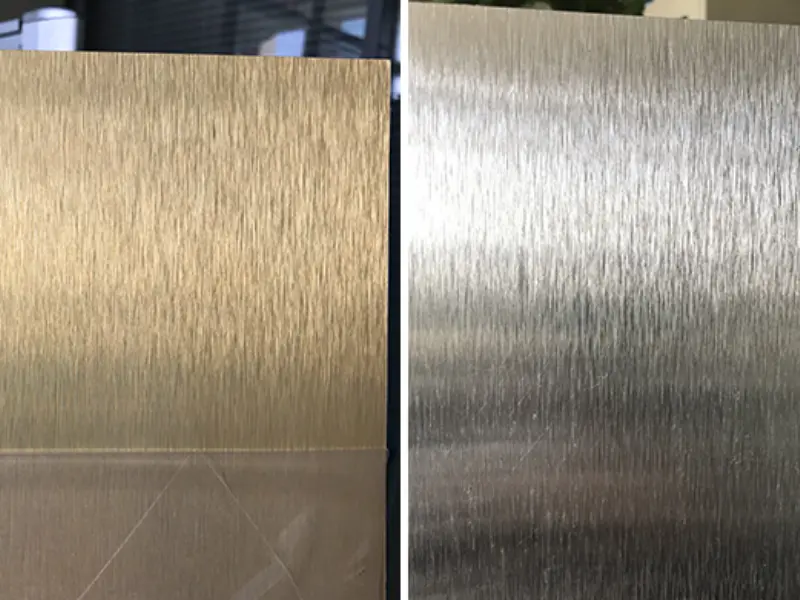

- Brushed Silver: This is the classic look, showing off the metallic sheen of the aluminum through the printed image.

- Brushed Gold: Offers a warm, luxurious feel, ideal for awards and premium signage.

- Brushed White: Features a white base layer with a brushed texture, providing a bright canvas for colors while retaining a subtle metallic hint.

- Coating Type: The sublimation coating is crucial. It ensures the ink transfers perfectly and the final image is sharp and long-lasting. Different coatings might offer varying levels of UV resistance or gloss.

Understanding these classifications helps you choose the best brushed aluminum sublimation sheet for your specific project.

Thickness of Brushed Sublimation Sheets

Brushed aluminum sublimation sheets are available in different thicknesses to suit various uses:

| Thickness (mm) | Common Use Case |

|---|---|

| 0.3 mm | Lightweight labels, small decorative items |

| 0.5 mm | Signs, photo panels, ID tags |

| 1.0 mm | Nameplates, commercial signage |

| 2.0 mm | Industrial signage, durable panels |

Alloy Information

The most common alloys used for brushed sublimation sheets include:

| Alloy | Features |

|---|---|

| 1060 | Pure aluminum, good for lightweight applications |

| 3003 | Good corrosion resistance, widely used in signage |

| 5052 | High strength, suitable for durable products |

Classification of Brushed Aluminum Sublimation Sheets

Brushed aluminum sublimation sheets come in various types, mainly classified by their surface finish and

Alloy Used in Brushed Aluminum Sublimation Sheets

Common alloys include:

- 1100 Series: Known for its excellent corrosion resistance and ductility (it can be easily formed). It’s often used for general-purpose applications.

- 3003 Series: This alloy is stronger than 1100 series while still offering good workability and corrosion resistance. It’s a very common choice for many aluminum products, including brushed aluminum sublimation sheets.

These alloys ensure the brushed aluminum sublimation sheet provides a stable and reliable base for your high-quality prints.

Packaging for Brushed Aluminum Sublimation Sheets

Proper packaging is essential to protect brushed aluminum sublimation sheets during shipping and storage.

- Protective Film: Each sheet often comes with a peel-off plastic film on the brushed side to guard against surface damage.

- Interleaving Paper: Sheets may be separated by special paper to prevent scratching between them.

- Sturdy Cartons/Crates: Multiple sheets are typically packed in strong cardboard boxes or wooden crates, often with additional padding, to ensure they arrive in perfect condition.

Good packaging means your brushed aluminum sublimation sheet arrives ready for printing.

Other Key Features and Benefits

Durability and Longevity

One of the biggest advantages of brushed aluminum sublimation sheets is their incredible durability. The images are infused into the coating, not just on top. This makes them highly resistant to:

- Scratches and abrasions

- UV fading from sunlight

- Moisture and humidity

- Chemicals and cleaning agents

This means your prints will look vibrant and new for many years, even in challenging environments.

Stunning Visual Appeal

The brushed texture beneath the image adds a unique metallic luster and depth that cannot be achieved with other printing methods. Colors appear rich and vivid, and details are exceptionally sharp. The elegant look of brushed aluminum sublimation sheet elevates any design.

Easy to Process

Working with brushed aluminum sublimation sheets is straightforward. The sublimation process involves printing your design onto special transfer paper, then using a heat press to transfer it to the aluminum. It’s a clean and efficient method for creating custom items.

Specifications of Brushed Aluminum Sublimation Sheets

Here’s a table showing common specifications for brushed aluminum sublimation sheets:

| Feature | Details |

|---|---|

| Material | High-grade Aluminum Alloy (e.g., 3003, 1100 Series) |

| Surface Finish | Brushed Silver, Brushed Gold, Brushed White |

| Coating | White, Clear (for showing brushed metal through design) |

| Thickness | 0.5mm (0.020″), 0.7mm (0.028″), 1.0mm (0.040″) |

| Standard Sizes | 12″ x 24″, 24″ x 48″, 48″ x 96″ (and custom sizes available) |

| Printing Method | Dye Sublimation (Requires heat press) |

| Properties | Scratch-resistant, UV-resistant, Waterproof, Easy to clean |

These specifications help you choose the ideal brushed aluminum sublimation sheet for your project.

Application Areas

The versatility and beauty of brushed aluminum sublimation sheets make them suitable for a wide range of applications:

- Awards and Trophies: Create prestigious and lasting recognition pieces.

- Indoor and Outdoor Signage: Durable and attractive signs for businesses, directional purposes, or informational displays.

- Art Prints: Photographers and artists can reproduce their work with incredible detail and a unique metallic sheen.

- Photo Panels: Turn cherished memories into stunning, long-lasting photo displays.

- Decorative Panels: Used in interior design for wall art, kitchen backsplashes, or custom decorative elements.

- Nameplates and Badges: Professional and durable identification.

- Custom Gifts: Personalized items like coasters, keychains, or plaques.

- Architectural Features: For modern and elegant design elements in buildings.

No matter the application, brushed aluminum sublimation sheets deliver a premium result.

Specification Table

| Item | Details |

|---|---|

| Product Name | Brushed Aluminum Sublimation Sheet |

| Surface Finish | Brushed Silver / Gold / Copper |

| Thickness Range | 0.3 mm – 2.0 mm |

| Standard Sizes | A4, A3, 12″x24″, Custom |

| Coating | Sublimation printable coating |

| Alloy | 1060 / 3003 / 5052 |

| Packaging | Protective film + carton/wooden case |

What is a Brushed Aluminum Sublimation Sheet?

A brushed aluminum sublimation sheet is a metal panel that has been specially treated to accept sublimation inks. The “brushed” finish gives it a unique, textured look, adding depth and sophistication to your designs. When heated, sublimation inks turn into a gas and infuse directly into the coating of the aluminum. This process creates a vibrant, permanent image that is scratch-resistant and fade-resistant. It’s not just a print on the surface; it’s part of the sheet itself.

Conclusion

Brushed aluminum sublimation sheets offer an unmatched combination of elegance, durability, and print quality. Their unique brushed texture adds a sophisticated touch, while the sublimation process ensures your images are vibrant and long-lasting. From beautiful art pieces to robust signage, these sheets provide a premium solution for anyone looking to create high-impact, custom prints. Choose brushed aluminum sublimation sheet for your next project and experience the difference in quality and appeal!