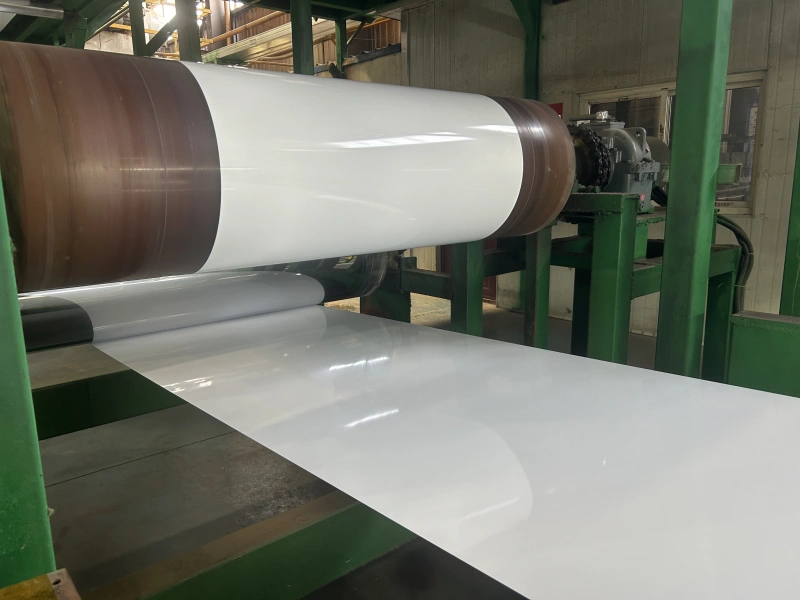

Glossy white aluminum sublimation sheets are premium metal substrates with a high-gloss white coating specifically engineered for dye-sublimation printing. These sheets feature an exceptionally smooth surface that produces brilliant, vibrant colors and sharp image details, making them ideal for high-quality visual applications.

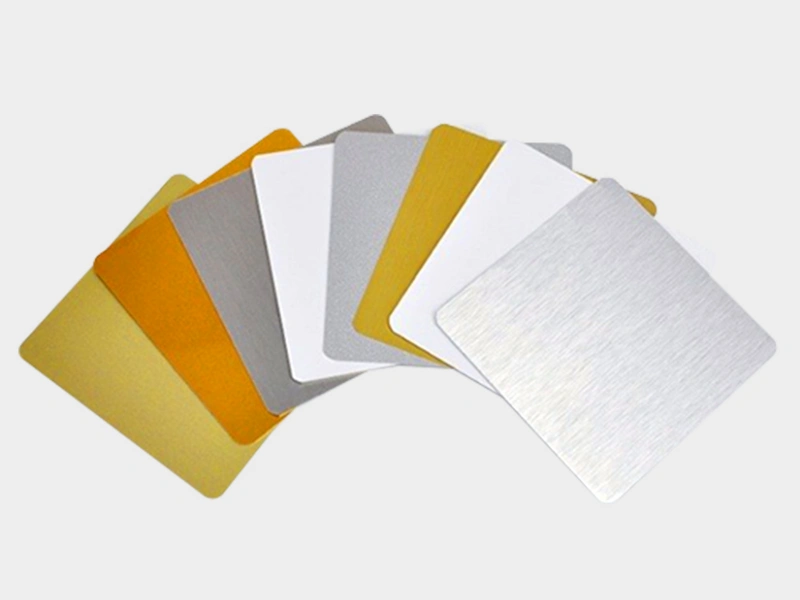

Classification

The term Glossy White Sublimation Aluminum Sublimation Sheet specifically refers to a finish that provides maximum shine and color saturation. While other finishes like matte or satin exist for aluminum sublimation, the “glossy white” variant is distinct for its mirror-like reflection and intense color reproduction, making images pop with a vivid, almost three-dimensional effect.

| Finish Type | Description | Key Characteristics | Ideal For |

|---|---|---|---|

| Glossy White | Features a brilliant, highly reflective surface that intensifies color vibrancy and depth. It creates a “wet” look, enhancing visual impact. | High reflectivity, maximum color pop, stunning clarity, deep blacks. | High-impact photography, vibrant art reproductions, premium signage, awards, high-end decor, commercial displays. |

The reflective quality adds a luxurious touch, making it a favorite for display pieces that demand attention.

Thickness Specifications

The thickness of your glossy white aluminum sublimation sheet plays a crucial role in its rigidity, durability, and overall suitability for specific applications. Thicker sheets offer enhanced strength and resistance to bending, making them ideal for larger or more permanent installations, while thinner options provide flexibility and lighter weight for certain uses.

| Thickness (mm) | Thickness (inches) | Common Applications for Glossy White Aluminum Sublimation Sheet |

|---|---|---|

| 0.30 mm | 0.012″ | Lightweight decorative items, small photo gifts, custom craft projects. |

| 0.45 mm | 0.018″ | Cost-effective photo panels, promotional displays, temporary event signage. |

| 0.50 mm | 0.020″ | Standard photo prints, medium-sized wall art, general indoor signage, personalized gifts. |

| 0.75 mm | 0.030″ | More robust signs, durable photo panels, framed art, displays requiring extra rigidity. |

| 1.00 mm | 0.040″ | Premium, rigid displays, heavy-duty signage, architectural accents, demanding commercial applications. |

| 1.50 mm | 0.060″ | Extra-strong panels, large format installations, high-traffic area displays requiring significant structural integrity. |

Selecting the appropriate thickness for your glossy white aluminum sublimation sheet ensures the longevity and presentation quality of your final product.

Alloy Composition

The aluminum alloy forms the foundation of every glossy white sublimation aluminum sheet, influencing its formability, corrosion resistance, and overall structural integrity. Manufacturers typically utilize alloys from the 1000 or 3000 series, known for their excellent surface quality, which is vital for the adhesion and performance of the sublimation coating.

- 1100 Series Aluminum: This alloy is prized for its high purity, exceptional ductility, and superb corrosion resistance. Its workability makes it an ideal base for creating smooth, consistent surfaces required for high-quality sublimation coatings. The 1100 series provides a stable and reliable substrate for your glossy white sublimation aluminum sheet.

- 3003 Series Aluminum: Incorporating manganese, the 3003 series offers increased strength (approximately 20% more rigid than 1100) while maintaining good formability and resistance to corrosion.

The careful selection of the aluminum alloy ensures that your sublimation sheets are not only visually striking but also structurally sound and resistant to environmental factors like rust.

Key Benefits of Glossy White Aluminum Sublimation Sheets

- Unparalleled Color Vibrancy: The high-gloss finish enhances every color.

- Exceptional Durability: Aluminum is inherently strong and resistant to bending, impacts, and general wear. The sublimation process permanently infuses the image into the coating, making it incredibly resilient.

- Scratch and Abrasion Resistant:

- UV Resistant: Prints on glossy white aluminum sublimation sheets are highly resistant to fading caused by sunlight exposure.

- Waterproof and Chemical Resistant: The non-porous surface repels moisture, spills, and can withstand cleaning with many common agents without damage.

- Lightweight for Easy Handling: Despite their strength, aluminum sheets are relatively light, simplifying transportation, installation, and display.

- Eco-Friendly Option: Aluminum is a highly recyclable material, positioning the glossy white aluminum sublimation sheet as a more sustainable printing solution.

Application Areas

The versatility and premium finish of glossy white aluminum sublimation sheets make them an outstanding choice for a diverse array of applications where visual impact and durability are paramount.

- Professional Photography & Fine Art: Producing museum-quality prints, art reproductions, and display pieces that require vibrant colors and sharp detail.

- Interior Decor: Stunning wall art, custom kitchen backsplashes, decorative panels, and unique furniture accents.

- High-End Signage & Displays: Eye-catching indoor and outdoor signs, sophisticated retail displays, trade show graphics, and promotional standees that grab attention.

- Awards & Recognition: Premium plaques, trophies, certificates, and corporate awards with a brilliant, lasting finish.

- Personalized Gifts: Custom photo panels, commemorative items, and personalized decor that demand a luxurious touch.

- Commercial & Corporate Branding: Branded wall art, office decor, and marketing materials that project a professional and vibrant image.

- Architectural Elements: Feature walls, decorative panels, and custom design elements in modern commercial and residential spaces.

- Educational & Museum Exhibits: Durable and engaging informational displays and interpretive panels.

Technical Specifications

| Parameter | Specification | Test Standard |

|---|---|---|

| Gloss Level | 85-100 GU | ISO 2813 |

| Whiteness Index | 90-95% | ISO 11475 |

| Coating Hardness | ≥3H | Pencil hardness test |

| Sublimation Temperature | 180-200°C | – |

| Sublimation Time | 30-60 seconds | – |

Quality Assurance

Reputable manufacturers provide:

✔ Consistent gloss level across batches

✔ Uniform coating thickness

✔ Perfect surface smoothness

✔ Color consistency certification

✔ Scratch resistance verification

Global Supply and Availability

Major production regions:

• China: Cost-effective manufacturing, large quantities

• Europe: Premium quality, high-grade materials

• North America: Quick delivery, custom solutions

Cost Considerations

Price factors include:

- Sheet thickness and size

- Order quantity

- Surface gloss level

- Packaging requirements

- Custom specifications

Note: 1.0mm thickness offers the best balance between cost and performance for most applications

Maintenance and Care

To maintain optimal appearance:

• Clean with soft microfiber cloth

• Use mild detergent if necessary

• Avoid abrasive cleaning materials

• Protect from sharp objects

• Store in dry, flat conditions

Environmental Performance

| Environment | Suitability | Expected Lifespan |

|---|---|---|

| Indoor controlled | Excellent | 8-10 years |

| Indoor general | Very good | 6-8 years |

| Outdoor protected | Good | 3-4 years |

| Direct outdoor | Fair | 2-3 years |

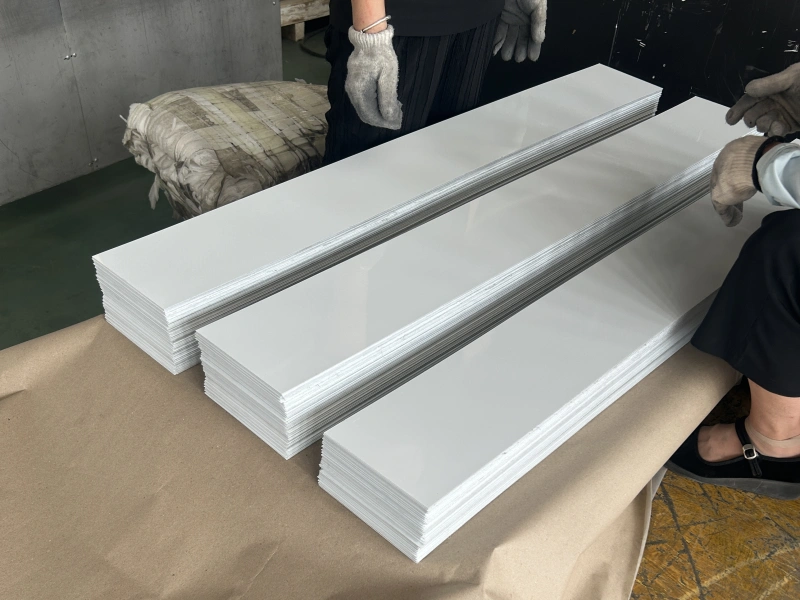

Packaging

Meticulous packaging is critical to ensure that every glossy white aluminum sublimation sheet arrives in flawless condition, ready for printing. Manufacturers implement a multi-layered protection system to safeguard against damage during transit.

- Protective Film: This film acts as a crucial barrier against scratches, dust, and minor abrasions during storage and handling.

- Interleaving Material:

- Robust Cartons/Crates:

- Edge and Corner Protection:

- Secure Strapping and Wrapping:

Choosing the Right Glossy White Aluminum Sublimation Sheet

Selecting the ideal glossy white aluminum sublimation sheet for your project:

- Intended Application: What is the finished product’s purpose? This will guide your decisions on required durability, thickness, and size. For instance, a high-traffic display might demand a thicker, more robust sheet than a framed art print.

- Desired Visual Impact: If maximum color vibrancy, a reflective sheen, and a “wow” factor are crucial, then a glossy white aluminum sublimation sheet is precisely what you need.

- Thickness Requirements: Match the sheet thickness to the desired rigidity and weight of your final product.

- Size and Form Factor: Ensure the chosen sheet size aligns with your project dimensions and fits your printing equipment efficiently, minimizing waste.

- Supplier Quality: Opt for reputable suppliers known for consistent, high-quality sublimation coatings, which are essential for reliable and vibrant print transfers.

Care and Maintenance

To preserve the vibrant appearance and pristine condition of your finished glossy white aluminum sublimation sheet prints:

- Cleaning: Use a soft, lint-free cloth with a mild, non-abrasive soap and water solution. Avoid harsh chemicals, scouring pads, or abrasive cleaners, which can damage the glossy coating.

- Handling: Always handle both raw sheets and finished prints with care, especially before the protective film is removed, to prevent accidental scratches or fingerprints.

- Storage: Store unused sheets flat in their original protective packaging in a cool, dry environment, away.

FAQs about Glossy White Aluminum Sublimation Sheets

Q: What makes glossy white aluminum sublimation sheets stand out from other sublimation blanks?

A: The “glossy white” finish is specifically designed to maximize color vibrancy and create a highly reflective, almost luminous appearance. The combination of aluminum’s durability with this brilliant coating results in a premium, long-lasting print that truly pops.

Q: Can these sheets be used outdoors?

A: Yes, absolutely. Glossy white aluminum sublimation sheets are inherently durable, UV resistant, and waterproof. When combined with high-quality sublimation inks and proper mounting, they perform exceptionally well in outdoor environments for signage and displays.

Q: Are glossy prints prone to glare?

A: While the glossy finish does create reflections, which can be perceived as glare in certain lighting conditions, it is also what gives the prints their incredible depth and vibrancy. For areas with very strong, direct light where glare is a major concern, a matte or satin finish might be considered, though it would sacrifice some of the intense color saturation.

Q: How long will my prints last on a glossy white aluminum sublimation sheet?

A: With quality sublimation inks and proper care, prints on glossy white aluminum sublimation sheets are incredibly long-lasting. They are resistant to fading, scratching, and moisture, ensuring your vibrant images remain stunning for many years, often decades.