Aluminum honeycomb panel in China is a lightweight and strong material widely used in construction, transport, furniture, and decoration. One of the key factors when choosing a honeycomb panel is density, which affects strength, weight, and cost. Aluminum honeycomb panel in China, with details about classification, thickness, alloy, and packaging.

Classification by Application

| Type | Core Density | Face Thickness | Primary Use |

|---|---|---|---|

| Architectural | 40-80 kg/m³ | 0.5-1.0mm | Building facades, ceilings |

| Industrial | 80-120 kg/m³ | 1.0-1.5mm | Machine covers, partitions |

| Transportation | 60-100 kg/m³ | 0.8-1.2mm | Vehicle interiors, marine |

| Clean Room | 50-90 kg/m³ | 0.7-1.0mm | Medical, electronic facilities |

Thickness Specifications

| Total Thickness (mm) | Face Sheet (mm) | Core (mm) | Weight (kg/m²) |

|---|---|---|---|

| 10 | 0.5+0.5 | 9 | 3.5-4.5 |

| 15 | 0.7+0.7 | 13.6 | 5.0-6.0 |

| 20 | 1.0+1.0 | 18 | 6.5-8.0 |

| 25 | 1.2+1.2 | 22.6 | 8.5-10.5 |

| 30 | 1.5+1.5 | 27 | 11.0-13.5 |

Aluminum Alloy Options

| Component | Alloy | Temper | Characteristics |

|---|---|---|---|

| Face Sheets | 3003 | H14/H24 | Good formability, weather resistance |

| Face Sheets | 5052 | H32 | Better strength, marine applications |

| Core Foil | 3003 | O | Excellent corrosion resistance |

| Edge Band | 6061 | T6 | Structural strength for framing |

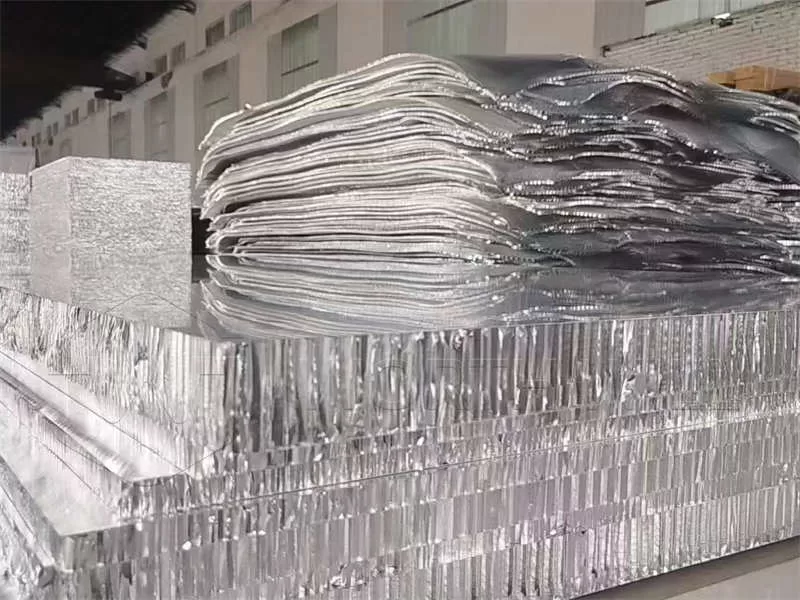

Packaging and Shipping

Standard Packaging

- Interior Protection: PE film + corner guards

- Bundle Size: 5-10 panels per pack

- Wooden Frame: Reinforced edges

- Weather Proofing: Waterproof wrapping

Export Packaging

- Wooden Crates: Custom-sized for containers

- Steel Strapping: Minimum 4 straps per crate

- Desiccant: Moisture control bags

- Marking: Fragile, keep dry labels

Technical Specifications

| Property | Standard Value | Test Method |

|---|---|---|

| Flatness | ≤1.5mm/m | GB/T 3880 |

| Peel Strength | ≥4.0 N/mm | ASTM D1781 |

| Compressive Strength | 2.5-7.0 MPa | ASTM C365 |

| Thermal Conductivity | 0.8-1.5 W/m·K | ISO 8301 |

Applications

Architecture & Construction

- Curtain wall systems

- Interior partition walls

- Elevator cabin panels

- Signage and display boards

Transportation

- High-speed train interiors

- Marine bulkheads

- Aircraft cabin components

- Bus and RV interiors

Industrial Uses

- Machine protection covers

- Clean room partitions

- Exhibition stand structures

- Solar panel backing

Quality Standards

Chinese Standards

- GB/T 1452: Honeycomb core performance

- GB/T 17748: Aluminum composite panels

- GB 8624: Fire resistance classification

International Certifications

- ISO 9001: Quality management

- ASTM E84: Surface burning characteristics

- EN 14509: Self-supporting double skin panels

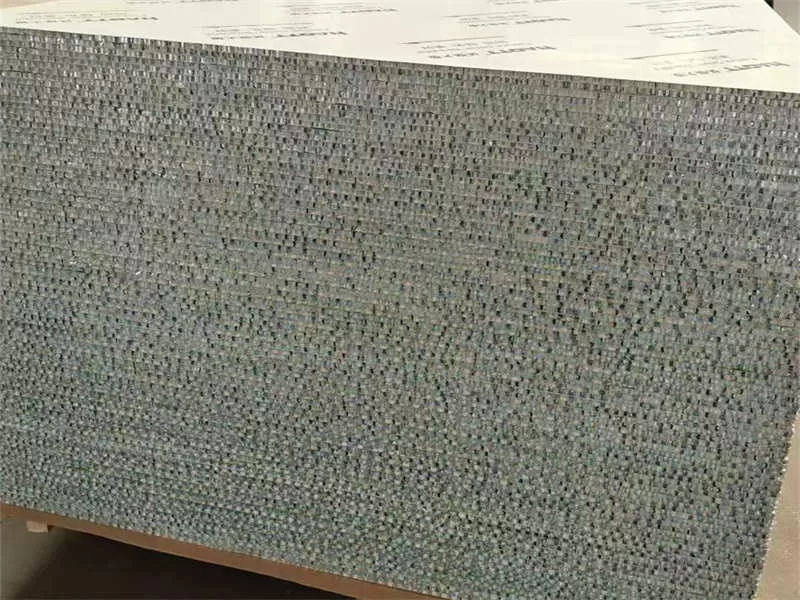

Manufacturing Process

- Core Expansion: Aluminum foil formed into honeycomb

- Face Sheet Preparation: Cleaning and pretreatment

- Adhesive Application: Epoxy or polyurethane bonding

- Hot Pressing: 120-180°C under pressure

- Curing: 24-48 hours at controlled temperature

- Cutting & Finishing: CNC cutting to size

Price Factors

| Factor | Price Impact |

|---|---|

| Thickness | 20mm = +40% vs 10mm |

| Face Alloy | 5052 = +25% vs 3003 |

| Quantity | 500+m²: 15% discount |

| Surface Finish | PVDF coating = +30% |

| Custom Size | Non-standard = +20% |

*Current price range: $25-80/m²*

Supplier Evaluation

Key Selection Criteria

Manufacturing experience (5+ years preferred)

Quality certifications (ISO 9001, etc.)

Minimum order quantity (typically 100m²)

Sample availability

Export experience

Major Production Regions

- Guangdong: High-quality architectural panels

- Jiangsu: Industrial and transportation panels

- Zhejiang: Cost-effective options

- Shandong: Large-scale production facilities

Installation Considerations

Use appropriate adhesives (epoxy, silicone)

Allow for thermal expansion (2mm per meter)

Handle with clean gloves to prevent stains

Store flat in dry conditions

Comparison with Alternatives

| Feature | Honeycomb Panel | Solid Aluminum | ACM Panel |

|---|---|---|---|

| Weight | 5-12 kg/m² | 8-24 kg/m² | 6-10 kg/m² |

| Stiffness | Excellent | Good | Fair |

| Cost | $$ | $$$ | $ |

| Flatness | Superior | Good | Very good |

What Are Aluminum Honeycomb Panels?

Aluminum honeycomb panels are sandwich-structured composites featuring aluminum face sheets bonded to an aluminum honeycomb core. Chinese manufacturers produce these panels with:

Excellent strength-to-weight ratio

Superior flatness and stiffness

Customizable sizes and specifications

Competitive pricing

Chinese Aluminum Honecyomb Panels

Chinese aluminum honeycomb panels offer exceptional performance and value for various applications. When selecting:

- Choose thickness based on span requirements

- Select alloy for environmental conditions

- Verify quality certifications

- Consider total project cost including shipping

Always request samples and test reports before placing large orders.