In the world of modern architecture and construction, choosing the right material for building facades, cladding, and interior applications is crucial. Two popular choices often considered are Aluminium Composite Panels (ACP) and Solid Aluminium Panels. While both are made from aluminium, their unique compositions and manufacturing processes lead to significant differences in performance, appearance, and application.

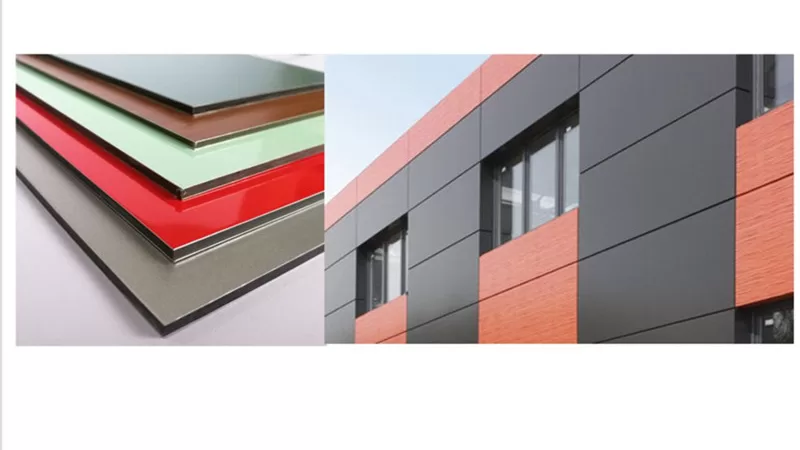

What is an Aluminium Composite Panel (ACP)?

An Aluminium Composite Panel (ACP) is a type of flat panel that consists of two thin aluminium sheets continuously bonded to a non-aluminium core. This core is typically made of polyethylene (PE) or a mineral-filled fire-retardant (FR) material. The outer aluminium skins are usually pre-finished with high-quality paint coatings like PVDF (Polyvinylidene Fluoride) or PE (Polyester), which offer excellent color stability and weather resistance. This multi-layered, “sandwich” structure is what gives ACPs their distinctive properties, making them a lightweight yet rigid building material.

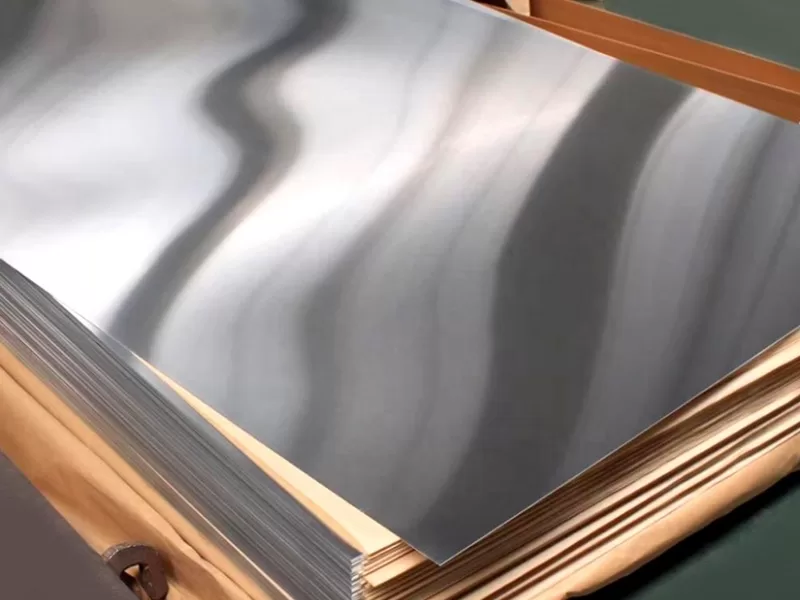

What is a Solid Aluminium Panel?

A Solid Aluminium Panel, often referred to simply as an aluminium panel or sheet aluminium, is a single, homogeneous sheet of aluminium metal. Unlike ACPs, there is no core material; the entire panel is made of a solid aluminium alloy. These panels are manufactured by rolling aluminium ingots into flat sheets of various thicknesses. They can also be coated with various finishes, similar to ACPs, to provide color and protection. Solid Aluminium Panels are known for their strength and pure metallic properties.

Key Differences: ACP vs. Solid Aluminium Panels

Understanding the core distinctions between these two aluminium building materials is essential. Here’s a detailed comparison:

| Feature | Aluminium Composite Panel (ACP) | Solid Aluminium Panel (Solid Aluminium Sheet) |

|---|---|---|

| Structure | Two thin aluminium skins bonded to a non-aluminium core (PE, FR mineral). | A single, homogeneous sheet of aluminium alloy. |

| Weight | Significantly lighter than a solid panel of comparable rigidity due to the low-density core. Ideal for lightweight cladding. | Heavier than ACP for the same rigidity and overall panel size. |

| Rigidity/Flatness | Excellent flatness and high rigidity-to-weight ratio, resisting oil-canning or warping in large sizes. | Can be prone to oil-canning (visual waviness) or warping in large, thin sheets without extensive reinforcement. |

| Fabrication | Very easy to cut, rout, fold, bend, and shape using standard tools. Allows for complex designs and precise angles. | Requires more specialized tools (welding, heavier bending machines) for shaping. Less flexible for certain designs. |

| Thermal Expansion | Lower thermal expansion due to the core material, leading to less visible distortion with temperature changes. | Higher thermal expansion, which needs careful consideration in design and installation to prevent buckling. |

| Cost | Generally more cost-effective for large, flat architectural applications compared to achieving similar rigidity with solid aluminium. | Can be more expensive, especially when considering the need for thicker material or additional stiffeners to achieve desired flatness. |

| Fire Safety | Standard PE core is flammable; Fire-Retardant (FR) ACPs with mineral cores offer enhanced fire safety. | Non-combustible by nature, but its melting point needs consideration in extreme fire scenarios. |

| Sound Insulation | Good sound and vibration dampening properties due to the composite structure. | Less inherent sound dampening; additional insulation layers might be needed. |

Specification Breakdown: ACP vs. Solid Aluminium

Both materials come in various specifications to meet different project needs.

Aluminium Composite Panels (ACP) Specifications:

| Specification Category | Details |

|---|---|

| Classification | Standard ACPs (PE Core): Cost-effective, good for interior & limited exterior use. Fire-Retardant ACPs (FR Core): Enhanced fire safety for building facades. Antibacterial ACPs: For hygienic environments. Mirror/Brushed Finish ACPs: For aesthetic applications. |

| Overall Thickness | 3mm: Common for interior, signage, and displays. 4mm: Most popular for exterior cladding and facades. 5mm-6mm: For larger panels or specific structural needs. |

| Aluminium Skin Thickness | 0.12mm – 0.50mm: Refers to the thickness of each outer aluminium layer. Thicker skins (e.g., 0.30mm, 0.40mm, 0.50mm) provide greater rigidity and durability, especially for external cladding. |

| Alloy | Typically Alloy 1100 or 3003: These aluminium alloys are chosen for their formability and corrosion resistance. |

| Packaging | Wooden Pallets: Standard for protection during transport, often wrapped in plastic film. Bulk Shipping: For very large orders, optimized for container space. |

Solid Aluminium Panels Specifications:

| Specification Category | Details |

|---|---|

| Classification | Aluminium Sheet: Thinner gauges, versatile for many applications. Aluminium Plate: Thicker gauges for structural or heavy-duty use. Aluminium Coil: Rolled sheet, often used for continuous processes. |

| Overall Thickness | 1.0mm – 6.0mm+: Solid panels are generally thicker than the skins of ACPs to achieve comparable rigidity. Common facade thicknesses might be 2mm, 3mm, 4mm, or 5mm. |

| Alloy | Wide range including Alloy 1100, 3003, 5052, 6061: Chosen based on desired strength, formability, corrosion resistance, and weldability. |

| Packaging | Protective Film: Often applied to the surface. Wooden Crates/Skids: For flat sheets and plates to prevent bending or damage. |

Applications: Where Each Panel Shines

Both ACP and Solid Aluminium Panels are excellent building materials, but their optimal use cases differ based on their inherent characteristics.

Applications of Aluminium Composite Panels (ACP):

ACPs are incredibly versatile due to their lightweight, rigid, and easy-to-fabricate nature.

- Building Facades and Exterior Cladding: Most common use for modern, sleek appearances.

- Interior Wall Linings and Partitions: Offers a clean, contemporary finish inside buildings.

- Signage and Advertising Boards: Smooth surface and ease of routing make them ideal for high-quality signs.

- Canopies, Soffits, and Column Covers: Providing aesthetic and protective coverings.

- Shop Fronts and Retail Design: Enhancing visual appeal with various colors and finishes.

- Ceilings and False Ceilings: Especially in large commercial spaces.

Applications of Solid Aluminium Panels:

Solid Aluminium Panels are favored when pure metal properties, structural integrity, or specific fabrication methods are required.

- Custom Fabricated Facade Elements: When complex curves, deep embossing, or unique structural shapes are needed that are difficult with ACP.

- Perforated Screens and Sunshades: The solid nature allows for intricate laser cutting or punching without delamination.

- Structural Components: Where the inherent strength of the aluminium alloy is critical.

- High-Impact Areas: In situations where the panel might experience direct heavy impact (though often thicker gauges are required).

- Welded Assemblies: For fully sealed, monolithic aluminium structures.

- Areas requiring non-combustible material (without relying on FR core): Where the strict non-combustibility of solid metal is a primary requirement.

Choosing the Right Panel: When to Use Which?

When deciding between Aluminium Composite Panels and Solid Aluminium Panels, consider your project’s specific needs:

- For large, flat, and aesthetically uniform surfaces where lightweight and cost-effectiveness are key, ACPs are generally the preferred choice, especially with FR ACP options for fire safety. They excel in achieving a flat, modern facade quickly and efficiently.

- For highly customized designs involving complex curves, intricate perforations, or welded components, or when the inherent strength and non-combustibility of a pure metal are paramount, Solid Aluminium Panels are often the better solution.

Both materials offer remarkable durability and design flexibility. Your final choice will depend on factors like budget, design complexity, desired aesthetic, fire safety requirements, and installation considerations.