Blank metal sublimation sheets are revolutionizing the printing and signage industry with their durability and vibrant print quality. Imagine turning your favorite photos into brilliant wall art, or creating custom signs and awards that truly stand out. That’s the power of metal sublimation blanks.

If you’re curious about how those incredibly sharp and vibrant images appear on metal, the secret lies in these specifically prepared sublimation sheets.

How Sublimation Printing Works with Metal

To fully appreciate blank metal sublimation sheets, it helps to understand the sublimation process in brief:

- Print Your Design: Your image is printed in reverse onto special sublimation transfer paper using a sublimation printer with specific inks.

- Prepare the Blank: The blank metal sublimation sheet is cleaned to ensure no dust or oils interfere with the transfer.

- Heat Press: The printed paper is placed face-down onto the coated side of the metal blank. Both are then placed into a heat press.

- Transfer: Under high heat (typically 380-400°F or 193-204°C) and pressure for a specific time (usually 45-90 seconds, depending on thickness), the ink on the paper sublimates.

- Reveal: Once the time is up, the paper is removed, revealing your permanent, vibrant image embedded within the polymer coating of the sublimation metal blank.

Blank Metal Sublimation Sheets Specifications

Understanding the technical aspects of blank metal sublimation sheets is key to selecting the right product for your project.

| Specification | Description | Common Ranges/Types |

|---|---|---|

| Classification | Blank metal sublimation sheets are classified by their primary metal type, the surface finish of the coating, and their physical dimensions (pre-cut shapes vs. large sheets). | Metal Type: Almost exclusively Aluminum. Surface Finish: Gloss White, Gloss Clear, Matte White, Matte Clear, Brushed Silver, Brushed Gold, ChromaLuxe (brand specific). Each offers a different look and feel. Form: Pre-cut blanks (e.g., photo panels, signs, keychains), large sheets (for custom cutting). |

| Thickness | This refers to the gauge of the metal substrate. The thickness affects the rigidity, durability, and perceived quality of the final product. | Commonly ranges from 0.5 mm (0.020 inches) to 1.5 mm (0.060 inches). Thicker sheets offer more rigidity and a premium feel, ideal for larger prints or outdoor signs. Thinner sheets are suitable for smaller items or applications where flexibility is needed. |

| Alloy | The type of aluminum alloy used in the sublimation metal blank impacts its strength, formability, and overall quality. | Typically 1100 series or 5052 series aluminum. 1100 Series: Known for excellent corrosion resistance and formability, commonly used for general-purpose sublimation blanks. 5052 Series: Offers higher strength and superior corrosion resistance, suitable for more demanding applications or larger panels where rigidity is crucial. |

| Packaging | How the blank metal sublimation sheets are packaged is crucial to protect the delicate polymer coating from scratches, dust, and damage during shipping and storage. | Individual sheets often come with a protective film (peel-off plastic) on the coated side. They are usually stacked with interleaving paper or foam, then packed securely in cardboard boxes or wooden crates. Bulk rolls or larger sheets might be shipped on pallets, carefully wrapped. |

Key Features and Benefits of Blank Metal Sublimation Sheets

The unique characteristics of blank metal sublimation sheets make them highly sought after:

- Exceptional Image Clarity: The prints are incredibly sharp, vibrant, and have a wide color gamut, often surpassing traditional photo paper. They create stunning photo panels.

- Durability: Images embedded into the coating are highly resistant to scratches, chemicals, moisture, and UV fading, making them suitable for both indoor and outdoor use.

- Lightweight: Aluminum, the primary material, is inherently light, making the final products easy to handle, hang, and transport.

- Modern Aesthetic: The sleek, often glossy or metallic finish of sublimation metal blanks provides a contemporary and high-end look.

- Easy to Clean: The smooth, hard surface can be easily wiped clean without damaging the image.

- Versatility: Available in various sizes, shapes, and finishes, catering to a broad range of creative projects.

Applications of Blank Metal Sublimation Sheets

The versatility and quality of blank metal sublimation sheets open up a world of possibilities across many industries and personal uses:

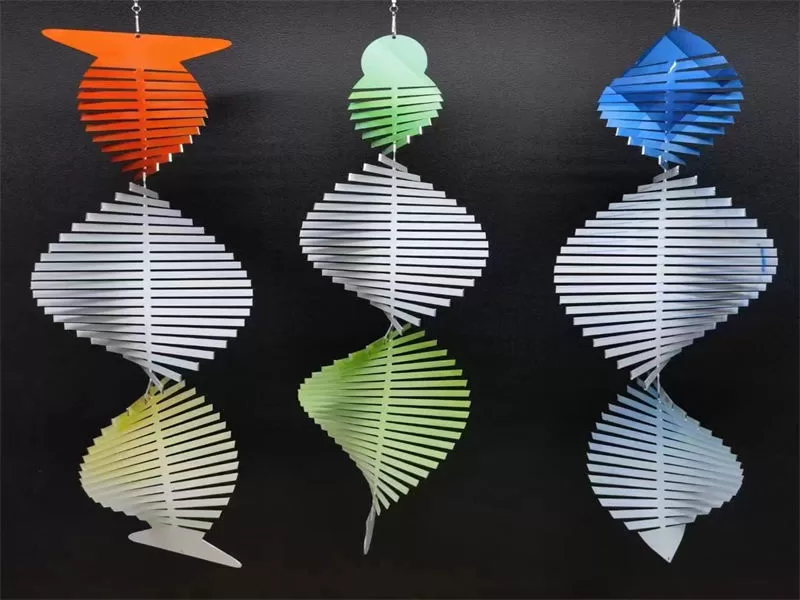

- Photography and Art Displays: Create stunning photo panels for galleries, homes, and offices. Images truly pop on metal, giving a modern, frameless look.

- Indoor and Outdoor Signage: Ideal for durable, weather-resistant signs for businesses, directional signs, and informational plaques.

- Awards and Recognition: Produce high-quality, professional awards, plaques, and trophies with vivid graphics and text.

- Personalized Gifts: Craft custom keychains, coasters, ornaments, bookmarks, pet tags, and other unique personalized items.

- Decorative Wall Panels: Use larger aluminum sublimation panels for unique interior design elements in homes or commercial spaces.

- Art Reproductions: Artists can reproduce their work on metal for unique, gallery-quality prints.

- Promotional Items: Create branded merchandise with a high-end feel for corporate giveaways and events.

Choosing the Right Blank Metal Sublimation Sheet

When selecting blank metal sublimation sheets, consider your end goal. Do you need a high-gloss finish for vibrant photos, or a matte finish to reduce reflections?

Will the item be outdoors, requiring maximum UV and scratch resistance? The thickness and alloy choice will also depend on whether you need a rigid, long-lasting sign or a thinner, lighter promotional item. Always ensure the blanks are from reputable suppliers to guarantee a consistent, high-quality polymer coating for the best sublimation results.

What Are Blank Metal Sublimation Sheets?

This coating is the crucial element that allows the magic of sublimation to happen. Without it, the metal surface would not be able to absorb the dyes from the sublimation ink.

The process of sublimation involves heat and pressure. When you print a design onto special sublimation paper using sublimation inks, and then press it onto the coated metal sublimation blank with a heat press, something incredible occurs.

The heat turns the solid sublimation ink into a gas (it “sublimes”). This gas then deeply penetrates and permanently bonds with the polymer coating on the metal. As the sheet cools, the gas turns back into a solid, trapping the image within the coating.

The result is a vibrant, durable, and scratch-resistant image that feels smooth to the touch, not like it’s simply sitting on top. This makes aluminum sublimation panels a premium choice for high-quality prints.