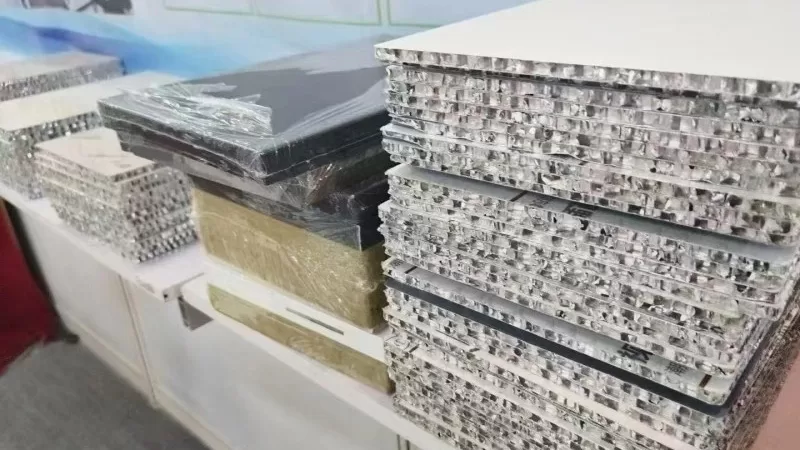

Honeycomb panels are celebrated as engineering marvels. They offer an incredible strength-to-weight ratio, making them a go-to material in industries from aerospace to architecture. But like any advanced material, honeycomb panels aren’t without their drawbacks.

1. Higher Initial Cost: An Investment Upfront

One of the most immediate disadvantages of honeycomb panels is their price tag. Compared to traditional solid materials or more common composite panels, honeycomb structures often come with a higher initial cost.

Why?

- Specialized Manufacturing: Their production involves precise processes and advanced bonding techniques.

- High-Quality Materials: The cores (aluminum, aramid fiber, thermoplastics) and skins (carbon fiber, fiberglass) are often premium materials.

While they can offer long-term savings through weight reduction and improved efficiency, the initial financial outlay can be a significant barrier for budget-sensitive projects.

2. Complex & Costly Repairs

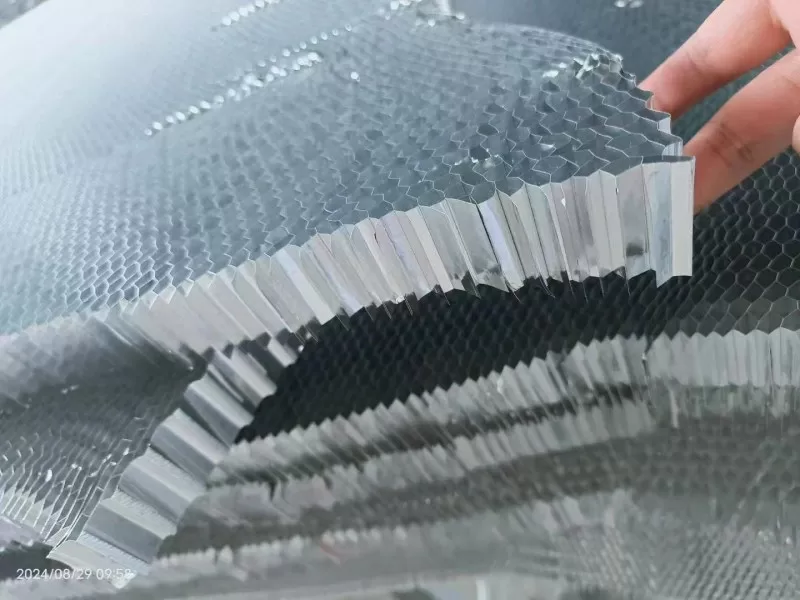

Damage to a honeycomb panel can be a real headache. Unlike a simple dent in a metal sheet, repairing the intricate internal structure of a honeycomb core is complex and often expensive.

- Intricate Core: The delicate cell structure makes localized patching difficult.

- Replacement Often Needed: Sometimes, entire sections or even the whole panel must be replaced, rather than just repaired.

- Specialized Skills & Tools: Repairing honeycomb composites requires specific expertise and equipment, adding to both time and cost.

This complexity can be a major concern in applications where quick, easy, and affordable repairs are essential.

3. Vulnerability to Moisture Ingress

Moisture is a silent enemy for many materials, and honeycomb panels (especially those with non-metallic cores) are no exception. If water finds its way into the core, it can lead to serious issues:

- Freezing Damage: Water freezing inside the cells can expand and destroy the core structure, leading to delamination.

- Corrosion/Mold: Moisture can cause corrosion in metallic cores or promote mold/mildew growth in organic ones.

- Sealing Challenges: Achieving a perfect, long-lasting seal on the edges to prevent water entry is critical but often challenging.

This makes moisture resistance a key consideration when evaluating the disadvantages of honeycomb panels for outdoor, marine, or high-humidity environments.

4. Susceptibility to Localized Impact Damage

While honeycomb panels excel at distributing loads, they can be surprisingly vulnerable to sharp, localized impacts.

- Crushed Cells: A concentrated blow (like a dropped tool or a sharp object) can crush the thin-walled cells of the core in that specific spot.

- Hidden Damage: This might create a dent or a “soft spot” on the surface, which can be hard to detect immediately.

- Compromised Performance: Even minor internal crushing can compromise the panel’s structural integrity over time, making it another significant point among the disadvantages of honeycomb panels.

5. Manufacturing Complexity & Quality Control

The sophisticated nature of honeycomb panel production contributes to their high cost and can also be considered a disadvantage in terms of accessibility.

- Precision Bonding: Thin face sheets must be perfectly bonded to the core under precise conditions of heat and pressure.

- Strict Quality Control: Any defect in the bond or materials can severely impact performance.

- High Investment: Manufacturers need significant investment in advanced machinery and highly skilled labor.

This complexity limits the number of producers and contributes to the material’s premium status.

6. Challenges in Joining and Connections

Connecting honeycomb panels to other structures or to each other isn’t always straightforward.

- Crushing Risk: Traditional fasteners like screws can crush the delicate core unless special, often costly, inserts are used.

- Adhesive Bonding: While preferred for its even stress distribution, adhesive bonding requires careful surface preparation and controlled curing.

- Increased Assembly Time: These specialized joining methods can make assembly slower and more precise than simply bolting together solid materials.

These unique requirements for joining are important disadvantages of honeycomb panels in large-scale assembly lines.

7. Situational Acoustic Properties

Honeycomb panels are often used for their good acoustic insulation due to trapped air. However, if extremely high levels of sound deadening are required, a standard lightweight honeycomb panel alone might not be sufficient compared to a much denser, solid material of the same thickness. Additional layers might be needed, adding to weight and thickness. This is a nuanced point, as their acoustic properties are generally positive, but they might not meet all extreme soundproofing needs without modification.

Understanding the Specifications

To truly understand honeycomb panels, it’s helpful to know how they are characterized:

Classification

Honeycomb panels are classified by their components:

- Core Material: E.g., aluminum, aramid (Nomex), paper, or thermoplastic. Each offers different properties.

- Face Sheet Material: E.g., aluminum, fiberglass, carbon fiber, HPL. This impacts strength, stiffness, and aesthetics.

- Cell Size: Affects shear strength and weight – smaller cells mean higher shear strength but can be heavier.

- Adhesive Type: Crucial for panel integrity and performance under various conditions.

Thickness

The thickness of honeycomb panels varies widely, from a few millimeters to several centimeters, depending on the application:

- Thin Panels (5-10mm): Ideal for lightweight partitions or decorative uses.

- Medium Panels (10-50mm): Common in aerospace, marine, and automotive for floors and walls, balancing strength and weight.

- Thick Panels (50mm+): Used in demanding applications like large architectural facades or bridges, where high stiffness is paramount.

The chosen thickness directly impacts the panel’s weight, stiffness, and, of course, cost, adding another layer to the consideration of the disadvantages of honeycomb panels.

When Honeycomb Panels Still Shine (Despite the Downsides)

Despite these disadvantages of honeycomb panels, their unique benefits make them indispensable in many industries:

- Aerospace: Aircraft interiors, wing components.

- Automotive: Lightweighting for performance cars and EVs.

- Marine: Yacht interiors, decks, bulkheads.

- Architecture: Modern facades, interior partitions.

- Rail: Train floors and ceilings.

- Wind Energy: Turbine blades.

- Sports Equipment: High-performance skis and bikes.

- Cleanrooms: Walls and ceilings due to smooth, non-shedding surfaces.

Conclusion

While honeycomb panels offer unparalleled strength-to-weight ratios and versatility, it’s vital to be fully aware of their disadvantages. These include higher costs, complex repairs, vulnerability to moisture and localized impact, and specific manufacturing and joining requirements.

By understanding these limitations, engineers, designers, and project managers can make more informed decisions, ensuring that the benefits of honeycomb panels truly outweigh their challenges for a given application. When used correctly, their advanced properties continue to push the boundaries of design and performance.