Mirror finish aluminium sheet stands out as a highly innovative and visually striking material. Engineered to provide an exceptionally smooth and reflective surface, akin to a traditional glass mirror, yet with the inherent advantages of aluminum. Whether you’re aiming for a sleek modern look or need superior light distribution, these polished aluminium sheets deliver unparalleled performance and visual appeal.

What Makes Mirror Finish Aluminium Sheet So Unique?

The magic of mirror finish aluminium sheet lies in its specialized manufacturing process, which transforms ordinary aluminum into a highly reflective surface. This involves precise polishing and, in some cases, an anodizing treatment, to create a durable, highly reflective layer.

Classification of Mirror Finish Aluminium Sheet:

Mirror finish aluminium sheet can be classified based on its reflectivity level and the specific treatment applied:

- 85% Reflectivity (Standard Mirror Finish): This offers a good balance of reflectivity and cost-effectiveness, suitable for many general decorative and lighting applications.

- 95% Reflectivity (Super Mirror Finish): Achieves near-perfect reflection, often used in high-precision lighting, solar reflectors, and premium decorative settings.

- Brushed Mirror Finish: A hybrid that combines the reflective quality with a subtle brushed texture, adding a unique aesthetic.

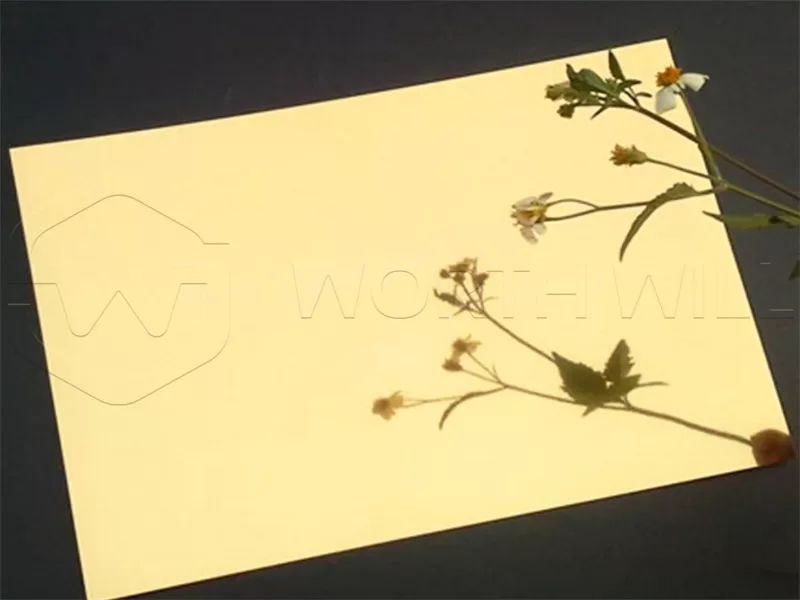

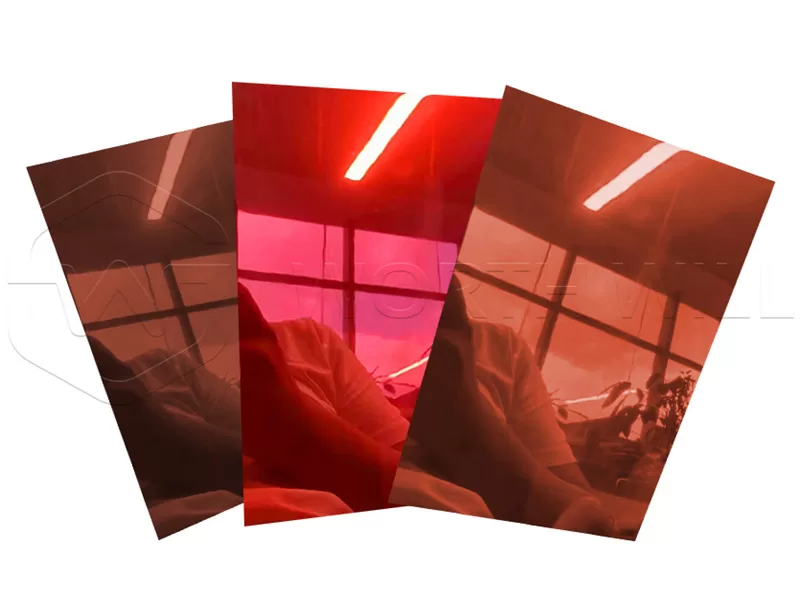

- Color Mirror Finish: Achieved through anodizing or coating, allowing for various vibrant or subtle colors while maintaining reflectivity.

Thickness Options for Every Need:

Our mirror finish aluminium sheet comes in a comprehensive range of thicknesses to suit diverse project requirements. Common thicknesses include:

- 0.3mm to 1.5mm: Ideal for decorative trims, lightweight panels, and signage.

- 1.5mm to 3.0mm: Suitable for more robust architectural applications, light fixtures, and automotive parts.

- Custom Thicknesses: We can provide tailored solutions to meet very specific demands, ensuring perfect fit and performance for your design.

Alloy Selection for Optimal Performance:

We primarily utilize aluminum alloys from the 1xxx series, such as Alloy 1050, 1060, and 1070. They also offer excellent formability, making it easy to bend, cut, and shape the reflective aluminium for intricate designs without compromising the surface quality. For specific applications requiring greater strength or corrosion resistance, other alloys like 3xxx or 5xxx series might be considered with appropriate surface treatments.

The Manufacturing Process Behind the Shine

Achieving a flawless mirror finish aluminium sheet involves several critical steps:

- Material Selection: Starting with high-purity aluminum coils from the 1xxx series.

- Rolling: The aluminum is rolled to the desired thickness.

- Polishing: This is the crucial stage where the surface is mechanically polished to an exceptionally smooth, bright finish using specialized equipment. This process meticulously removes surface imperfections and creates the highly reflective surface.

- Anodizing (Optional but Recommended): For enhanced durability, corrosion resistance, and scratch resistance, the polished surface can undergo an anodizing process. This electrochemical treatment creates a hard, clear oxide layer that protects the polished aluminium sheet without dulling its shine. It also allows for the integration of colors.

- Protective Film: A temporary, peel-off protective film is applied to shield the delicate mirror surface during transport and fabrication.

Key Features and Advantages of Mirror Finish Aluminium Sheet

Opting for mirror finish aluminium sheet brings a multitude of benefits to any project:

- High Reflectivity: Offers exceptional light reflection, making it perfect for lighting fixtures, solar applications, and creating bright, expansive spaces.

- Lightweight: Significantly lighter than traditional glass mirrors, reducing structural load and making installation easier and more cost-effective.

- Superior Corrosion Resistance: Aluminum naturally forms a protective oxide layer, further enhanced by anodizing, providing excellent resistance to rust and corrosion, even in challenging environments.

- Durable and Break-Resistant: Unlike glass, aluminium mirror sheet is far more resistant to shattering or cracking, making it safer for public spaces and areas prone to impact.

- Easy to Fabricate: Can be easily cut, drilled, bent, and formed using standard tools, allowing for complex designs and custom shapes.

- Aesthetic Appeal: Provides a sleek, modern, and high-end look, enhancing the visual appeal of any design.

- Cost-Effective Alternative: Often more economical than stainless steel mirrors or other highly reflective metals, offering premium aesthetics at a more accessible price point.

- Environmentally Friendly: Aluminum is 100% recyclable, making mirror finish aluminium sheet a sustainable choice for environmentally conscious projects.

Versatile Applications of Mirror Finish Aluminium Sheet

The unique properties of mirror finish aluminium sheet make it an incredibly versatile material, utilized across numerous industries:

- Lighting Reflectors: Essential for optimizing light distribution in LED lighting, fluorescent fixtures, and industrial lighting, maximizing lumen output.

- Architectural and Decorative Applications: Used for interior wall cladding, ceiling panels, column covers, decorative trims, and facades, creating a sense of openness and sophistication.

- Signage and Displays: Provides a striking background for signs, billboards, and display stands, drawing attention with its brilliant reflection.

- Automotive Industry: Employed for interior trim, decorative elements, and reflective components, adding a touch of luxury and modern design.

- Solar Energy Reflectors: Crucial in solar concentrators and parabolic troughs to efficiently direct and focus sunlight for energy generation.

- Consumer Electronics: Used in decorative elements for appliances, televisions, and other electronic devices.

- Furniture Design: Incorporated into tables, chairs, and other furniture pieces for a contemporary, reflective finish.

- Kitchenware and Appliances: Applied for decorative panels and reflective surfaces in high-end kitchen appliances.

- Clean Room and Laboratory Construction: Its smooth, easy-to-clean surface is ideal for environments requiring high hygiene standards.

Why Choose Our Mirror Finish Aluminium Sheet?

When selecting mirror finish aluminium sheet for your project, quality and reliability are paramount. We are committed to providing products that not only meet but exceed industry standards.

- Superior Quality Control: Our manufacturing process adheres to strict quality control measures at every stage, from raw material inspection to final product verification. This ensures consistent reflectivity, thickness, and surface integrity.

- Advanced Polishing Technology: We utilize state-of-the-art polishing equipment and techniques to achieve the highest possible reflectivity and surface smoothness.

- Customization Capabilities: We offer a wide range of sizes, thicknesses, alloys, and optional anodized finishes, including various colors, to perfectly match your unique project specifications.

- Reliable Supply: With efficient production capabilities and robust logistics, we ensure timely delivery of your orders, regardless of size.

Conclusion

Mirror finish aluminium sheet is more than just a material; it’s a statement of brilliance, innovation, and practical design. Its unique combination of high reflectivity, lightweight properties, exceptional durability, and ease of fabrication makes it an indispensable component across numerous industries.