2 inch wide aluminum strips are a remarkably versatile and widely used material in various industries and DIY projects. Their specific dimension – a narrow yet manageable width – makes them ideal for applications requiring precision, lightweight properties, and excellent corrosion resistance. From intricate architectural details to robust industrial components, these aluminum strips offer a blend of aesthetic appeal and functional benefits.

What are 2 Inch Wide Aluminum Strips?

At its core, a 2 inch wide aluminum strip is exactly what its name suggests: a flat, elongated piece of aluminum that measures precisely two inches across. The specific width makes them manageable for various tasks where broader sheets would be cumbersome, or narrower wires insufficient.

Classification of 2 Inch Wide Aluminum Strips

The classification of 2 inch wide aluminum strips goes beyond just their width. They can be categorized based on several key characteristics that influence their suitability for different applications. Understanding these distinctions is crucial for selecting the right material for your specific needs.

By Thickness (Gauge)

The thickness, often referred to as gauge, is a critical factor determining the strip’s strength, flexibility, and weight. 2 inch wide aluminum strips are available in a range of thicknesses:

- Thin Gauges (e.g., .010″ to .032″): These are highly flexible and easy to bend, ideal for decorative trim, shims, or applications where lightweight flexibility is paramount.

- Medium Gauges (e.g., .040″ to .080″): Offering a good balance of strength and workability, these are common for bracing, small structural supports, and general fabrication.

- Thick Gauges (e.g., .090″ and up): Providing maximum rigidity and strength, suitable for load-bearing applications, heavy-duty brackets, or components requiring minimal flex.

By Surface Finish

The surface finish affects both the aesthetic and functional properties of the aluminum strip.

- Mill Finish: This is the natural, untreated appearance of the aluminum as it comes off the mill, typically a dull, matte metallic look. It’s cost-effective and common for applications where appearance is not critical or where it will be further processed.

- Brushed Finish: Achieved by abrading the surface in one direction, creating a subtle, directional texture that reduces reflectivity and provides a modern, satin look.

- Polished Finish: Results in a highly reflective, mirror-like surface, often used for decorative purposes or where a bright, clean appearance is desired.

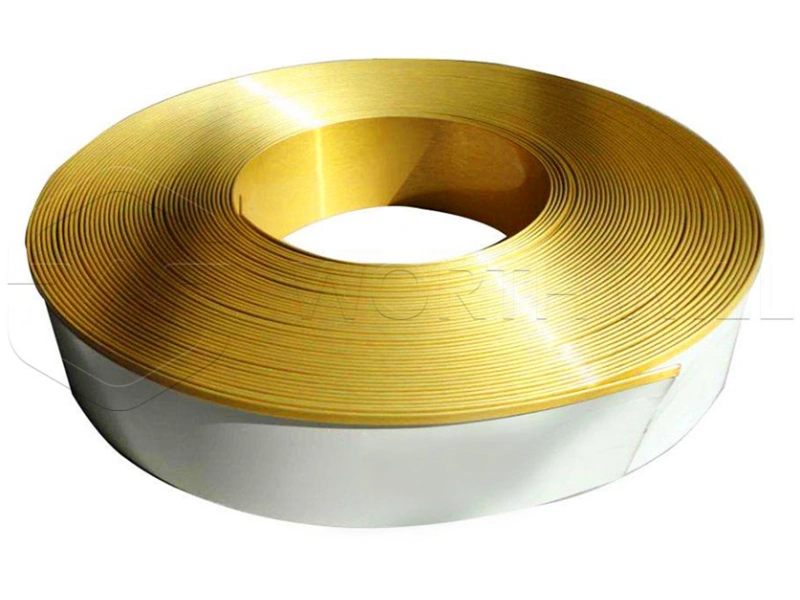

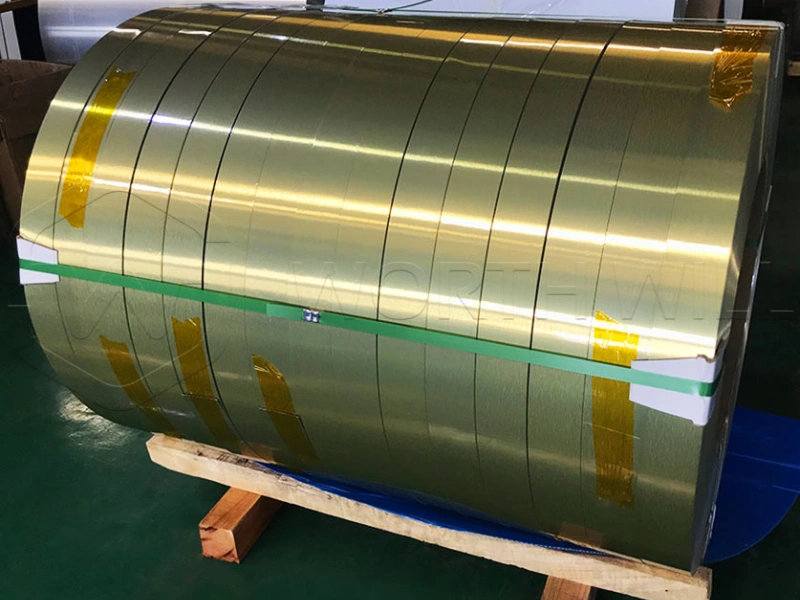

- Anodized Finish: An electrochemical process that creates a thicker, more durable, and corrosion-resistant oxide layer on the surface. It can also be dyed various colors, offering enhanced aesthetics and protection.

- Painted or Coated: Strips can be pre-painted or coated with various materials to add color, provide extra protection, or enhance specific properties like non-stick.

By Temper

The temper of aluminum refers to its hardness and strength, which is controlled by heat treatment and/or work hardening.

- Annealed (O Temper): Softest and most ductile, ideal for applications requiring extensive forming, deep drawing, or bending without cracking.

- Work Hardened (H Temper): Achieved through mechanical deformation, these tempers (e.g., H14, H32) offer increased strength and rigidity, commonly used for general fabrication where some formability is still needed.

- Solution Heat-Treated (T Temper): These alloys are strengthened by a controlled heat treatment process, resulting in high strength and hardness. Examples include T6, suitable for structural applications.

By Edge Condition

The way the strip’s edges are finished can be important for safety and specific applications.

- Slit Edge: The edge created directly by the slitting process, which can be sharp.

- Deburred Edge: The sharp burrs from slitting are removed, making the edge safer to handle.

- Safety Edge (or Rounded Edge): The edges are rounded off, providing maximum safety and a finished look, often for exposed applications.

The Alloy of 2 Inch Wide Aluminum Strips

The alloy used for 2 inch wide aluminum strips is perhaps the most critical factor, as it defines the fundamental physical and chemical properties of the material. An alloy is a mixture of aluminum with small percentages of other elements like silicon, iron, copper, manganese, magnesium, chromium, or zinc.

Common Aluminum Alloys for Strips

Different alloy series are chosen based on the desired performance of the aluminum strips:

- 1xxx Series Alloys (e.g., 1100): These are commercially pure aluminum alloys (at least 99% pure). They offer excellent corrosion resistance, high thermal and electrical conductivity, and are very ductile. This makes them easy to form, bend, and weld.

- 3xxx Series Alloys (e.g., 3003): Manganese is the primary alloying element, significantly improving strength compared to the 1xxx series while retaining good formability and corrosion resistance. Alloy 3003 is one of the most widely used general-purpose alloys for aluminum strips. It’s common in roofing, siding, storage tanks, and various fabricated parts.

- 5xxx Series Alloys (e.g., 5052): Magnesium is the main alloying element, providing excellent strength and superior corrosion resistance, especially in marine environments and against saltwater. It also has good weldability.

- 6xxx Series Alloys (e.g., 6061): These alloys contain silicon and magnesium, making them heat-treatable for increased strength. Alloy 6061 is highly versatile, offering good strength, excellent corrosion resistance, and good machinability and weldability. It’s often used for structural components, frames, and where a combination of strength and workability is needed.

The selection of the appropriate alloy for 2 inch wide aluminum strips is a key engineering decision that ensures the material performs optimally in its intended environment and application.

Manufacturing Process of Aluminum Strips

Aluminum strips, including the 2 inch wide variety, are typically produced from larger aluminum coil stock. The process usually involves:

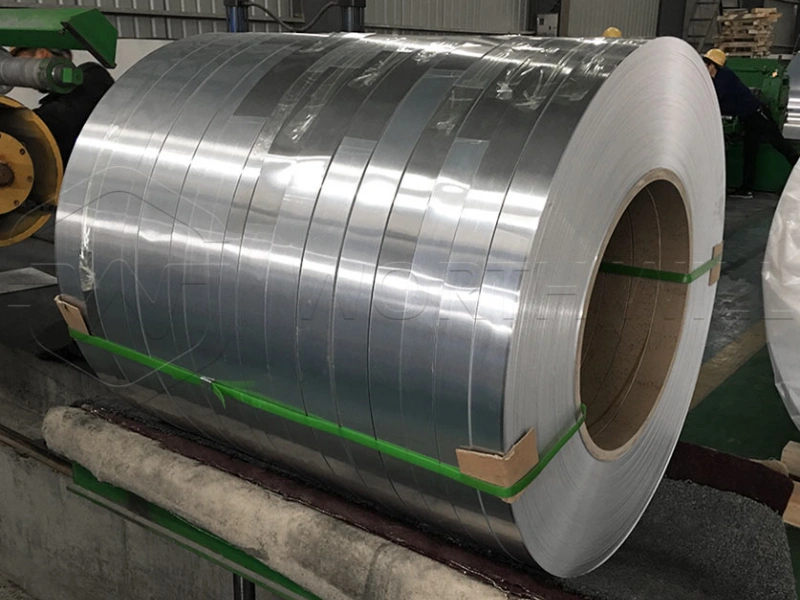

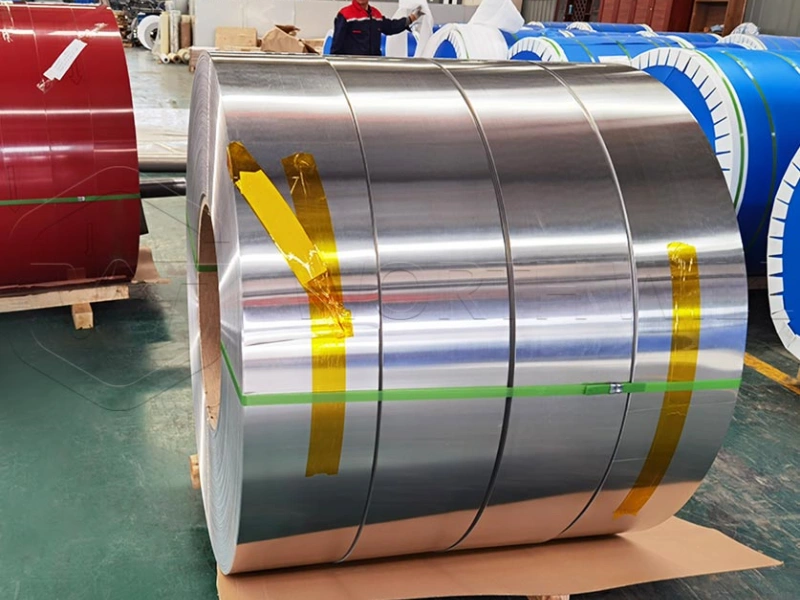

- Rolling: Large aluminum ingots are hot-rolled and then cold-rolled into thin sheets or wide coils of specific thickness.

- Slitting: The wide aluminum coil is then fed into a slitting machine. This machine uses precision rotary blades to cut the wide coil lengthwise into multiple narrower strips of the desired width, such as 2 inch wide aluminum strips.

- Coiling or Cutting to Length: The newly slit aluminum strips can then be recoiled for easy transportation and storage, or they can be cut into specific lengths depending on customer requirements.

- Finishing: Any additional finishing processes like deburring, anodizing, painting, or polishing are applied.

Key Features and Benefits of 2 Inch Wide Aluminum Strips

The combination of the material itself and its specific dimensions gives 2 inch wide aluminum strips a unique set of advantages:

- Lightweight: Aluminum’s low density makes these strips easy to handle, transport, and install, reducing overall project weight.

- Excellent Corrosion Resistance: Naturally resistant to rust and many chemicals, especially with proper alloy and finish.

- High Strength-to-Weight Ratio: Provides significant strength without adding bulk, crucial for many applications.

- Versatility: Can be bent, cut, welded, drilled, and formed into various shapes.

- Non-Magnetic: Ideal for sensitive electronic applications or environments where magnetism is an issue.

- Good Electrical and Thermal Conductivity: Useful in electrical applications or heat dissipation.

- Aesthetic Appeal: Can be polished, brushed, or anodized for decorative purposes.

- Recyclable: Aluminum is 100% recyclable without loss of properties, making it an environmentally friendly choice.

Application Areas of 2 Inch Wide Aluminum Strips

The specific size and properties of 2 inch wide aluminum strips make them exceptionally suitable for a wide range of applications:

- Construction:

- Flashing and weatherproofing

- Edge trim and decorative accents

- Spacers and shims

- Small bracing elements

- Automotive:

- Interior and exterior trim

- Heat shields and sound deadening components

- Gaskets and seals

- Electrical and Electronics:

- Busbars and electrical conductors (due to conductivity)

- Enclosures and mounting brackets for small components

- Heat sinks for electronic devices

- HVAC Systems:

- Ductwork reinforcement and connections

- Fin stock for coils

- Crafts and DIY Projects:

- Picture frame backing and hanging hardware

- Model making and prototyping

- Decorative accents on furniture or art pieces

- Signage:

- Framing elements for small signs

- Mounting brackets for display panels

- Marine:

- Non-structural interior trim (especially corrosion-resistant alloys like 5052)

- Small fastening plates

- Industrial:

- Machine guards and protective covers

- Label holders and identification tags

- Tooling components

Maintenance and Care for Aluminum Strips

2 inch wide aluminum strips are inherently low-maintenance. For most applications, periodic cleaning with mild soap and water is sufficient to keep them looking good. For outdoor or harsher environments, selecting an appropriate alloy and finish (like anodizing) will enhance their longevity and performance. Their resistance to rust means they won’t degrade like steel in moist conditions, requiring less intervention.