A3003 H14 is a widely recognized and highly valued aluminum alloy, known for its excellent balance of properties. It’s a popular choice across many industries due to its reliability and performance. When you need a material that offers good strength, impressive corrosion resistance, and easy workability, A3003 H14 often comes to mind.

Specification

A3003 H14 is a non-heat treatable aluminum alloy widely used for general-purpose sheet metal applications. It offers excellent corrosion resistance, good workability, and moderate strength.

- Alloy: A3003

- Temper: H14 (strain-hardened, half-hard)

- Thickness: 0.2mm – 6.0mm

- Width: 100mm – 2000mm

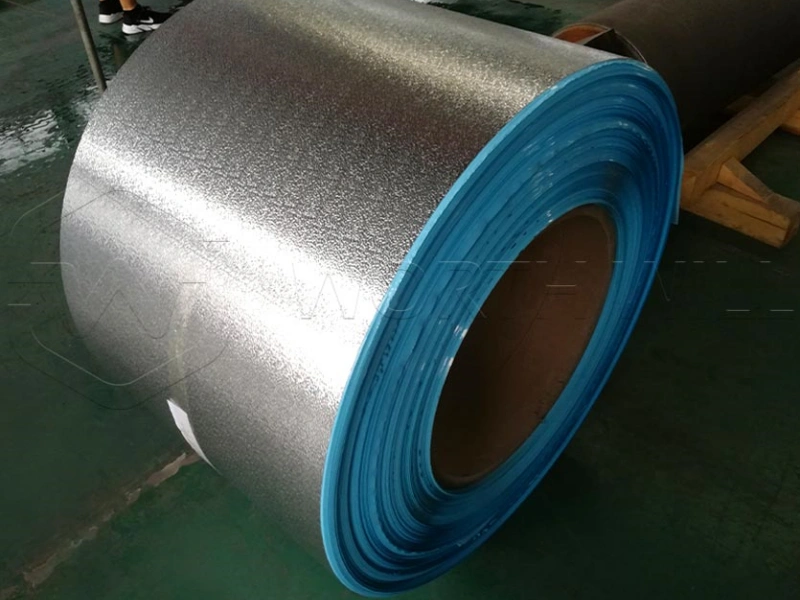

- Surface: Mill finish, stucco embossed, coated

- Standards: ASTM B209, GB/T 3880

Classification of A3003 H14

A3003 H14 aluminum can be classified by:

- Form:

- Aluminum sheet

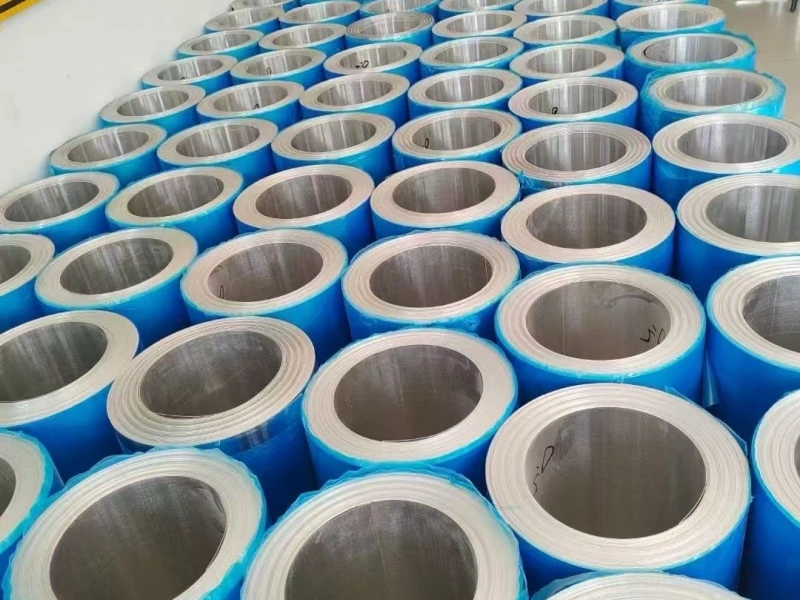

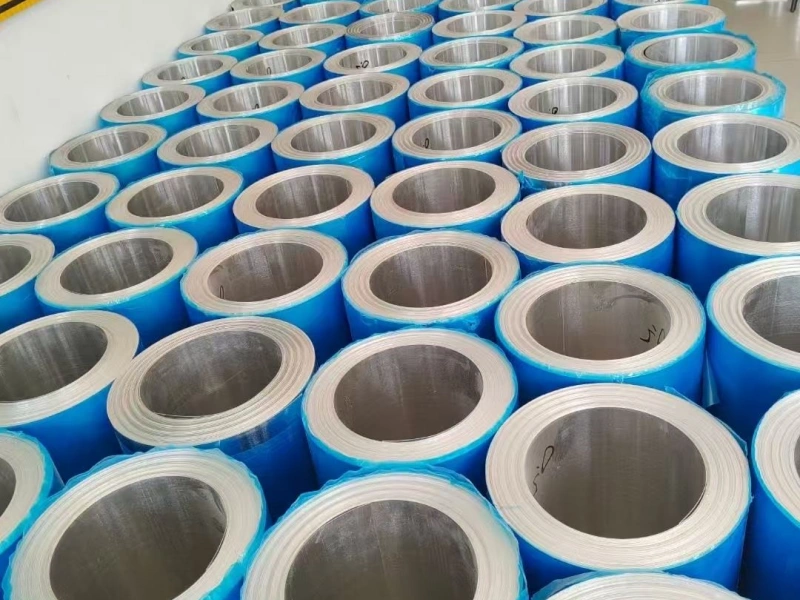

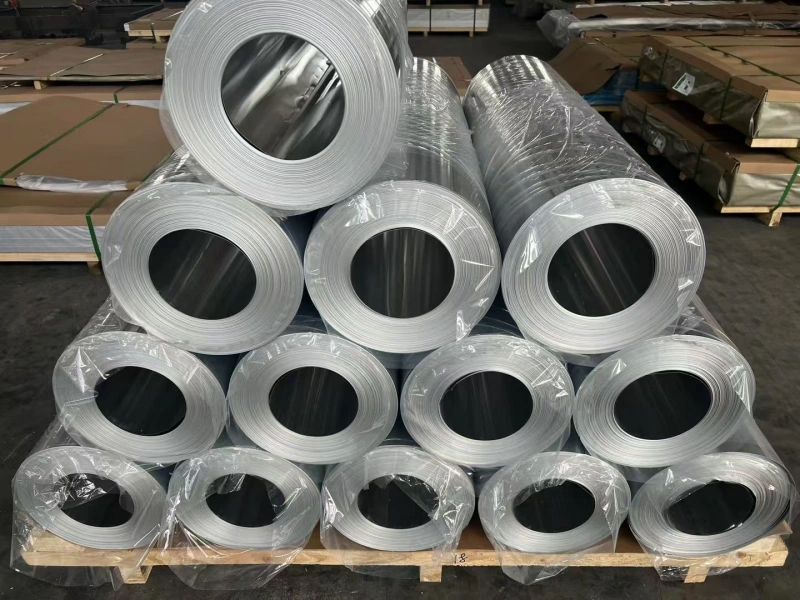

- Aluminum coil

- Embossed sheet

- Aluminum strip

- Surface Finish:

- Plain

- Stucco

- Color coated

- PVDF or PE coated

- Application Type:

- Architectural

- Food and packaging

- Automotive and transportation

Common Applications of A3003 H14

A3003 H14 is one of the most commonly used aluminum alloys across various industries. Its versatility and durability make it suitable for:

Construction & Architecture:

- Roofing sheets

- Cladding panels

- Gutter systems

- Ceiling tiles

HVAC & Insulation:

- Ducting

- Insulation jacketing

- Flexible air ducts

Food & Packaging:

- Aluminum foil containers

- Cookware and kitchen utensils

- Food storage equipment

Transportation:

- Trailer siding and panels

- Truck toolboxes

- RV and caravan construction

Alloy Composition of A3003

| Element | Percentage (%) |

|---|---|

| Aluminum (Al) | 96.8 – 99.0 |

| Manganese (Mn) | 1.0 – 1.5 |

| Copper (Cu) | 0.05 – 0.20 |

| Iron (Fe) | ≤ 0.7 |

| Silicon (Si) | ≤ 0.6 |

This composition gives A3003 its strength and corrosion resistance, making it better than pure aluminum like 1100 alloy for certain environments.

Alloy Composition: The main alloying element in A3003 is manganese, typically around 1.0% to 1.5%. This manganese content is crucial for enhancing its strength. Other minor elements like copper (around 0.05% to 0.20%) are also present, contributing to its overall properties. This specific composition gives A3003 H14 its unique characteristics, making it a preferred choice for various manufacturing needs.

Key Features and Benefits of A3003 H14 Aluminum

A3003 H14 aluminum alloy stands out because of its impressive set of features:

- Excellent Corrosion Resistance: One of the most significant advantages of A3003 H14 is its superior resistance to atmospheric corrosion and many chemical environments. This makes it ideal for outdoor applications or uses where exposure to moisture is common. This corrosion resistance ensures a longer lifespan for products made from this alloy.

- Good Formability and Workability: The “H14” temper indicates that this alloy is strain-hardened and then partially annealed. This process gives A3003 H14 excellent formability, meaning it can be easily bent, drawn, or spun into various shapes without cracking. Its good workability makes it easy to fabricate, reducing manufacturing costs and time.

- Moderate Strength: While not as strong as some heat-treatable alloys, A3003 H14 offers moderate strength, which is perfectly adequate for many applications where high strength-to-weight ratio is not the primary concern. It provides a good balance between strength and ductility.

- Excellent Weldability: A3003 H14 is highly weldable using common welding techniques, including MIG and TIG welding. This ease of joining makes it very versatile for complex assemblies and structures.

- Cost-Effective: Compared to some specialized alloys, A3003 H14 is generally more economical, offering a great balance of performance and price. This makes it a popular choice for large-scale production.

Understanding the “H14” Temper

The “H14” designation in 3003 H14 is very important. It refers to the temper of the aluminum alloy, which describes its hardness and strength.

- “H” indicates that the alloy has been strain-hardened. This means it has been strengthened through cold working, such as rolling or drawing, which changes its internal structure.

- “1” in the “14” signifies that it has been strain-hardened only.

- “4” in the “14” indicates the degree of hardness. On a scale of 0 to 8 (where 0 is annealed and 8 is full hard), “4” means it is “half-hard.” This half-hard temper provides a good balance of strength and formability, making A3003 H14 easy to work with while still offering good structural integrity.

This specific temper ensures that 3003 H14 sheet and plate materials have consistent mechanical properties, which is vital for reliable manufacturing processes.

Common Applications of A3003 H14 Aluminum Alloy

The versatility of 3003 H14 makes it suitable for a wide range of applications across various industries. Its properties make it a preferred material for many general-purpose uses.

- HVAC Systems: Used extensively in heating, ventilation, and air conditioning (HVAC) ductwork, heat exchangers, and condenser fins due to its corrosion resistance and formability.

- Chemical Equipment: Ideal for tanks, pipes, and containers that handle various chemicals, thanks to its excellent resistance to chemical corrosion.

- Food and Beverage Industry: Employed in food processing equipment, storage tanks, and cooking utensils because it is non-toxic and resistant to food acids.

- General Sheet Metal Work: Widely used for general fabrication, architectural trim, and decorative parts due to its ease of forming and aesthetic appeal.

- Storage Tanks: Perfect for storing water, oil, and other liquids where corrosion resistance is key.

- Pressure Vessels: Used in low-pressure applications where its moderate strength and weldability are beneficial.

- Building Products: Found in roofing, siding, and other construction components.

- Automotive Components: Used for certain non-structural parts where its light weight and corrosion resistance are advantageous.

Why Choose A3003 H14 for Your Project?

Choosing 3003 H14 aluminum alloy means opting for a material that delivers consistent performance and value. Its combination of excellent corrosion resistance, ease of fabrication, and moderate strength makes it a highly practical choice for a vast array of industrial and commercial applications. Whether you are designing HVAC systems, manufacturing chemical tanks, or creating general sheet metal products, 3003 H14 offers a reliable and cost-effective solution. Its widespread availability as 3003 H14 sheet, plate, and coil further enhances its appeal, ensuring that you can easily source the material in the form you need.

How Aluminum 3003 H14 Compares to Other Alloys (Briefly)

While other aluminum alloys like 5052 (stronger, better marine corrosion resistance) or 6061 (heat-treatable, higher strength) exist, 3003 H14 fills a specific niche. It’s generally more affordable and easier to form than 5052, and while not as strong as 6061, its superior weldability and corrosion resistance for many common environments make it a go-to for general-purpose applications where extreme strength isn’t the primary requirement. It strikes an excellent balance, making it a versatile and popular choice.

What Is A3003 H14 Aluminum Alloy?

3003 H14 is an aluminum-manganese alloy with around 1.2% manganese. The H14 temper indicates that the material is strain-hardened to a half-hard condition, making it easy to bend and shape but still strong enough for structural use.

Key Properties:

- Excellent resistance to corrosion (especially against moisture and chemicals)

- High ductility and formability

- Good weldability

- Moderate strength

- Lightweight and easy to cut

Why Choose 3003 H14 for Your Project?

- Corrosion Resistant: Ideal for marine and humid environments.

- Economical: Cost-effective compared to other aluminum alloys.

- Formable: Great for roll forming, bending, and stamping.

- Weldable: Compatible with standard welding methods.

FAQs About A3003 H14 Aluminum

Is A3003 H14 good for roofing?

Yes, it is widely used in roofing sheets due to its lightweight, rust resistance, and formability.

What is the difference between 3003 H14 and 1100?

While 1100 is almost pure aluminum, A3003 contains manganese, which increases strength and corrosion resistance.

Can A3003 H14 be anodized?

It can be anodized but the finish may be less bright than other alloys like 5052 or 6061.

How to Buy A3003 H14 Aluminum Sheet from China

China is one of the largest suppliers of A3003 H14 aluminum sheet and coil. Purchasing directly from manufacturers offers cost advantages and flexible customization.

Why Source from Chinese Suppliers?

- Competitive factory prices

- Fast production and delivery

- Custom thickness and width available

- Surface finishes like stucco, painted, or laminated

- Export-ready packaging

Contact a Reliable A3003 H14 Supplier

Looking for high-quality A3003 H14 aluminum sheets or coils?