Color coated aluminium coilcurtain wall is a pre-painted metal product specifically engineered for curtain wall systems, featuring:

PVDF or polyester coatings for weather resistance

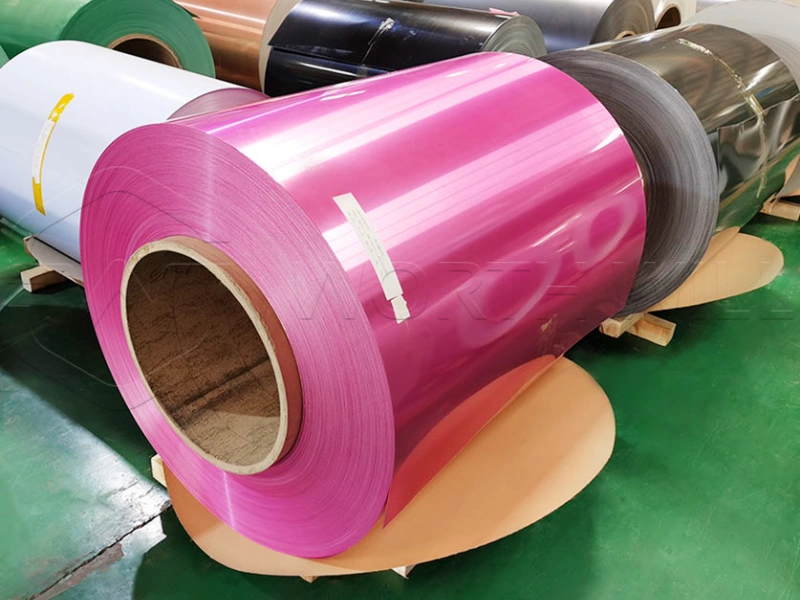

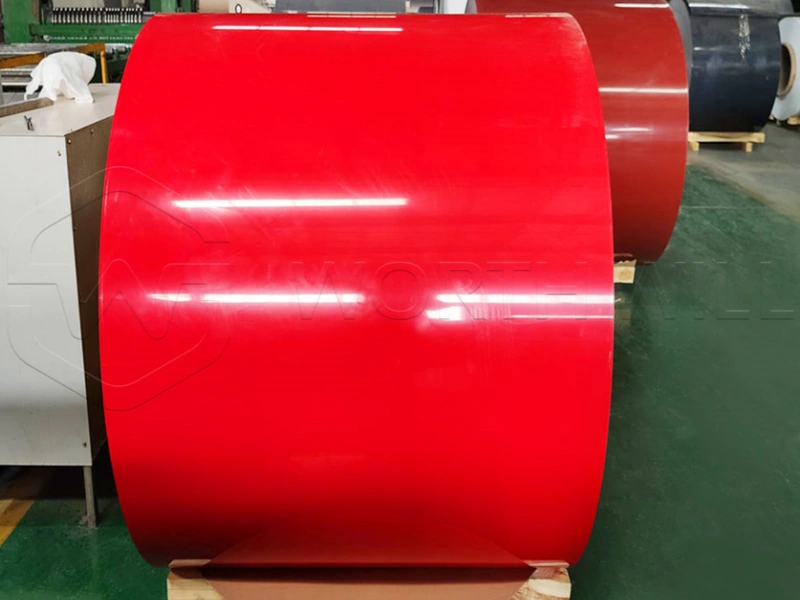

30+ color options (RAL, Pantone matches)

Custom thickness (0.5mm-4.0mm)

UV protection against fading

Technical Specifications

| Parameter | Specification |

|---|---|

| Alloy | 3003, 3004, 3005, 5005 |

| Temper | H14, H16, H18, H24, H32 |

| Coating | PVDF (70% fluoropolymer) / Polyester |

| Thickness | 0.5mm-4.0mm (±0.02mm) |

| Width | 600mm-1600mm |

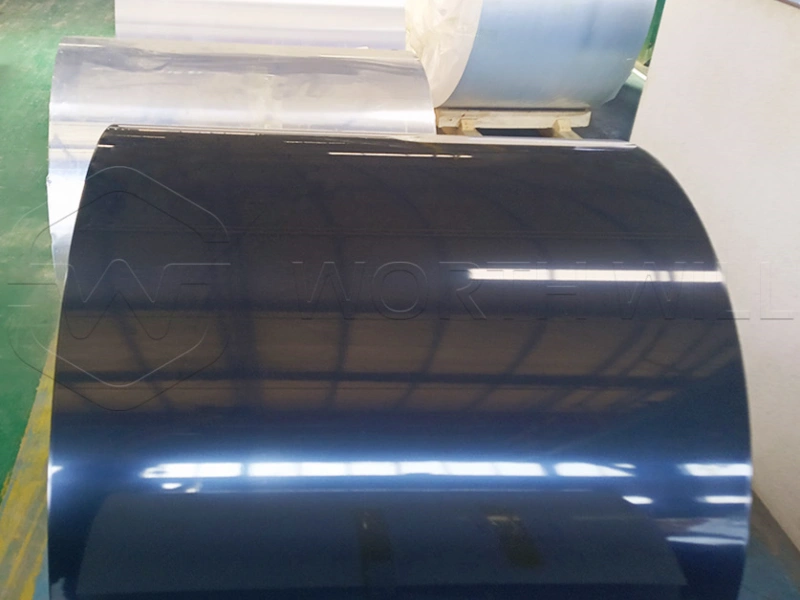

| Finish | Glossy, Matte, Metallic, Embossed |

5 Key Advantages for Curtain Walls

1. Superior Durability

- 25-30 year lifespan (PVDF coating)

- Salt spray resistance >3,000 hours

2. Aesthetic Flexibility

- Stucco embossed textures available

- Color consistency across batches

3. Lightweight Strength

- 1/3 the weight of steel

- High strength-to-weight ratio

4. Low Maintenance

- Self-cleaning properties (PVDF)

- Resists dirt accumulation

5. Sustainability

- 100% recyclable

- Reduces building energy costs

Surface Treatment Options

1. PVDF Coated

- Best for: Coastal/high-pollution areas

- Features: Chemical resistance, self-cleaning

2. Polyester Coated

- Best for: Indoor/mild climates

- Features: Cost-effective, good flexibility

3. Embossed Finishes

- Stucco – Fine granular texture

- Wood Grain – Natural appearance

- Brushed – Linear satin finish

Curtain Wall Applications

Commercial Buildings

- Office towers

- Shopping malls

- Airport terminals

Residential Projects

- High-rise facades

- Balcony screens

- Sunshades

Specialty Structures

- Canopy systems

- Column covers

- Decorative screens

Why Choose Our Coils?

20+ years curtain wall experience

ISO 9001 & Qualicoat certified

Custom color matching service

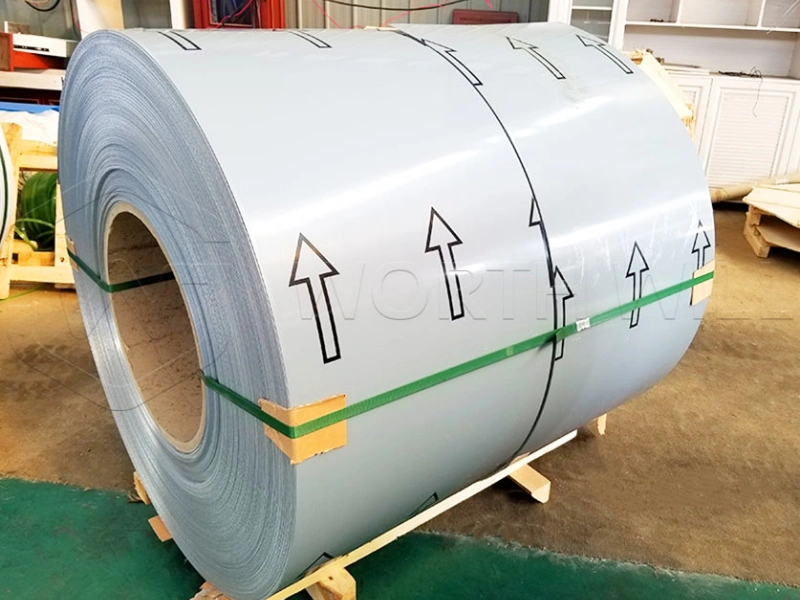

Global shipping with edge protection

Installation Tips

- Storage: Keep coils dry and flat

- Handling: Use edge protectors

- Fabrication: Clean cutting tools regularly

- Maintenance: Annual water rinse

Color Coated Aluminum Coil from China Manufacturers

Color coated aluminum coil is a versatile and durable material widely used in modern construction, particularly for curtain walls. Sourced from leading China manufacturers, this material offers a combination of aesthetic appeal, weather resistance, and ease of installation. This page provides an overview of color coated aluminum coil, its applications in curtain wall systems, and the benefits of using pre-painted aluminum for building projects.

Coated Aluminum Coil (PVDF/Polyester)

Color coated aluminum coil is typically coated with either PVDF (Polyvinylidene Fluoride) or Polyester paint systems. PVDF coatings offer superior durability and resistance to UV radiation, making them ideal for exterior applications where color retention and longevity are critical. Polyester coatings provide a cost-effective alternative for interior applications or areas with less exposure to harsh weather conditions. The choice between PVDF and Polyester depends on the specific project requirements and budget considerations.

Color Coated Aluminum Coil Curtain Wall

Curtain walls are non-structural outer walls of a building, typically made of lightweight materials such as aluminum and glass. Color coated aluminum coil is an excellent choice for curtain wall cladding due to its:

- Lightweight: Reduces the overall load on the building structure.

- Durability: Provides long-lasting protection against the elements.

- Design Flexibility: Available in a wide range of colors and finishes to achieve desired aesthetics.

- Ease of Installation: Simplifies the construction process and reduces labor costs.

Stucco Embossed Color Coated Aluminum Coil

Stucco embossed color coated aluminum coil adds texture and visual interest to curtain walls. The embossed surface enhances the material’s rigidity and reduces glare, making it a popular choice for architectural designs that require a unique and eye-catching appearance. This type of aluminum coil is often used in commercial buildings, shopping malls, and residential complexes.

Buy China Supplier Prepainted Aluminum Curtain Wall

Sourcing pre-painted aluminum curtain wall materials from China suppliers can offer significant cost savings without compromising quality. Many reputable manufacturers in China produce high-quality color coated aluminum coil that meets international standards. When sourcing from China, it’s essential to:

- Verify the supplier’s credentials: Check for certifications and quality control processes.

- Request samples: Evaluate the color, finish, and durability of the material.

- Negotiate payment terms: Ensure a secure and transparent transaction.

Pre-Fabrication Solid Aluminum Sheet for Curtain Wall

Pre-fabrication of solid aluminum sheets for curtain walls offers numerous advantages, including:

- Reduced on-site labor: Components are manufactured off-site, minimizing the need for cutting and fabrication at the construction site.

- Improved accuracy: Precise manufacturing ensures consistent quality and dimensional accuracy.

- Faster installation: Pre-fabricated panels can be quickly installed, accelerating the construction timeline.

Color Coated Aluminum Coil Used for Building Curtain Wall

Color coated aluminum coil is a preferred material for building curtain walls due to its versatility and performance characteristics. Its ability to be formed into various shapes and sizes allows architects to create innovative and visually stunning designs. Furthermore, the protective coating provides long-term resistance to corrosion, fading, and other forms of degradation, ensuring the curtain wall maintains its appearance and functionality for years to come.

Applications of Color Coated Aluminum Coil in Curtain Walls:

- Commercial buildings

- Office towers

- Shopping centers

- Residential complexes

- Public facilities (schools, hospitals, airports)

- Renovation projects

By choosing color coated aluminum coil for your curtain wall project, you can achieve a balance of aesthetics, performance, and cost-effectiveness. Its durability, design flexibility, and ease of installation make it an ideal material for modern construction.

Frequently Asked Questions

1. PVDF vs Polyester for curtain walls?

- PVDF: 30+ year lifespan, best for harsh climates

- Polyester: 15-20 year lifespan, budget-friendly

2. Minimum bending radius?

1.5x material thickness (e.g., 3mm for 2mm coil)

3. How to clean coated surfaces?

Mild soap + water (avoid abrasive cleaners)

4. Lead time for custom colors?

15-20 days (standard colors ship in 7 days)

Ordering Information

- MOQ: 1 ton (samples available)

- Packaging: Waterproof wrapping + wooden pallets

- Delivery: 15-30 days worldwide

Request free color charts today!