At Worthwill Aluminum, we manufacture and supply sublimation sheet metal with superior surface quality, ideal for dye-sublimation printing, UV printing, and engraving. Our products combine excellent adhesion, color clarity, and durability—making them a top choice for personalized printing, signage, nameplates, and more.

Surface Options:

| Surface Finish | Color Options |

|---|---|

| Pearlized | Gold, Silver, White |

| Brushed | Gold, Silver, Copper |

| Satin (Glossy) | Gold, Silver |

| Titanium | Gold, Silver |

| Mirror Finish | Gold, Light Gold, Silver |

| High Gloss / Matte | White |

| Gloss Colors | Black, Red, Blue |

These finishes provide different visual effects to meet the needs of various markets and printing applications.

Exploring the Variety: Types of Sublimation Aluminum Sheets

One of the exciting aspects of sublimation sheet metal is the sheer variety of finishes available. This allows for incredible creative freedom. Here are some of the popular choices we offer for our Series of Sublimation Aluminum Sheet / UV Printing Aluminum Sheet (0.25mm-1.0mm):

Pearlized Finishes:

Pearlized Gold (珠光金)

Pearlized Silver (珠光银)

Pearlized White (珠光白)

Brushed Finishes:

Brushed Gold (拉丝金)

Brushed Silver (拉丝银)

Silver Copper (拉丝铜) – Note: The provided translation was “Silver Copper” for “拉丝铜”, often it’s Brushed Bronze or Copper.

Satin Finishes (often referred to as亮面 – Bright/Satin):

Satin Gold (亮面金)

Satin Silver (亮面银)

Titanium Finishes:

Titanium Silver (钛银)

Titanium Gold (钛金)

Glossy & Matte Whites:

High Glossy White (高光白) – A very popular sheet metal for sublimation gloss white.

Matte White (哑光白)

Mirror Finishes:

Mirror Gold (镜面金)

Mirror Light Gold (镜面浅金)

Mirror Silver (镜面银)

Our hot-sale products include the High Glossy, Pearlized, Brushed, Satin, Matte, Mirrored, and Titanium Gold/Silver series. We are committed to continuously developing new series to fully meet the diverse needs of our clients.

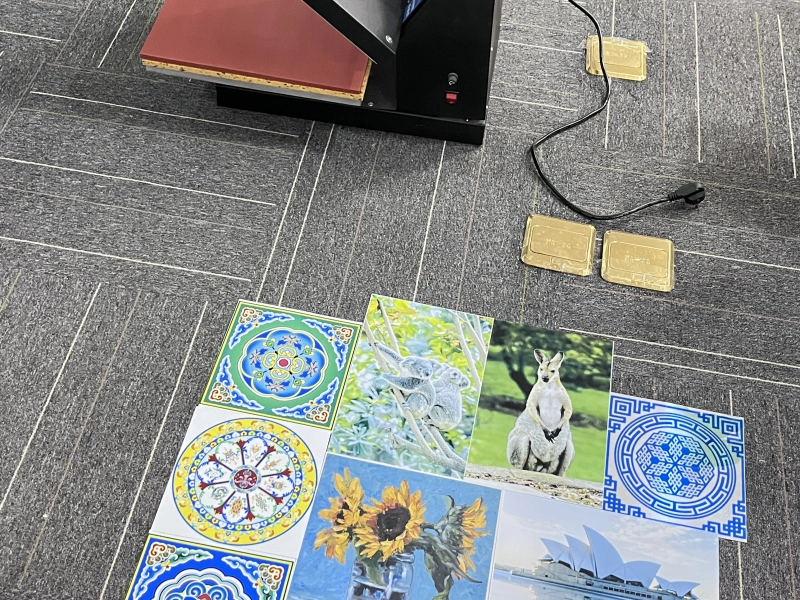

The Sublimation Process: How Designs Come to Life on Metal

Transforming a plain sublimation aluminum blank into a vibrant piece of art involves a few key steps:

Design Creation: Create or choose your digital image.

Printing: Print the image onto sublimation transfer paper using sublimation inks. Remember to mirror your image!

Preparation: Secure the printed transfer paper to the sublimation metal sheet with heat-resistant tape.

Heat Pressing: Place the sheet in a heat press. The specific temperature and time will vary depending on your equipment, the thickness of the metal, and the specific sublimation blanks.

What Temperature Do You Sublimate Metal Sheets?

Generally, temperatures for sublimating on metal range from 350°F to 400°F (approximately 175°C to 205°C). The duration can vary from 45 seconds to a few minutes. It’s crucial to consult the manufacturer’s recommendations for your specific sublimation aluminum sheet and heat press for optimal results.

How to Make a Sublimation Metal Sheet (Print on It)?

As described above, “making” a sublimation metal sheet from a user’s perspective means printing your design onto it. You’re not manufacturing the coated sheet itself but rather applying your custom graphics to a pre-coated sublimation aluminum blank. The process involves your digital design, sublimation inks, transfer paper, and a heat press.

Key Features and Customization

Our sublimation aluminum sheets, UV printing aluminum sheets, and engraving aluminum sheets are typically available in the following thicknesses:

0.25 mm

0.35 mm

0.45 mm

0.65 mm

0.8 mm

1.0 mm

Beyond these standard options, the specification and dimension can also be customized to meet your specific project requirements. This flexibility makes our aluminum sheets ideal for a wide range of applications.

Applications: Where Can You Use Sublimation Metal Sheets?

The versatility of sublimation sheet metal makes it suitable for a vast array of applications, both personal and commercial. Here are just a few ideas:

Signage: Indoor and outdoor signs, informational plaques, wayfinding signs.

Photography: High-definition photo reproductions with exceptional clarity and color depth.

Awards and Trophies: Custom plaques, medals, and awards.

Promotional Products: Branded name badges, coasters, magnets, and keychains.

Interior Decor: Custom wall art, kitchen backsplashes (with appropriate sealing for high-wear areas), and decorative panels.

Personalized Gifts: Photo panels, custom license plates, and unique keepsakes.

Industrial Applications: Nameplates for machinery, control panel overlays.

Artistic Reproductions: Creating durable and vibrant copies of artwork.

A Nod to Engraving: Series of Engraving Aluminum Sheet

While sublimation offers vibrant color, we also cater to needs for sleek, engraved finishes. Our Series of Engraving Aluminum Sheet includes popular options like:

Gloss Black (亮黑)

Gloss Red (亮红)

Gloss Blue (亮蓝)

These are perfect for applications requiring a classic, durable engraved look.

What’s All the Buzz About Sublimation Sheet Metal?

Have you ever wondered how stunning, photo-quality images appear on metal surfaces like signs, plaques, or custom gifts? The answer often lies in sublimation sheet metal. This innovative material allows for vibrant, durable, and high-resolution prints that embed directly into a specially coated metal surface. If you’re looking for a way to create eye-catching and long-lasting designs on metal, exploring sublimation aluminum sheet options is a fantastic start. This guide will walk you through what it is, its benefits, and how you can use it.

What Exactly is a Sublimation Metal Sheet?

A sublimation metal sheet is typically an aluminum sheet that has been treated with a special polymer coating. This coating is crucial because it’s designed to absorb sublimation inks. During the sublimation process, heat and pressure turn these inks into a gas, which then permeates the coating. As it cools, the ink solidifies and becomes a permanent part of the metal sheet. The result is a high-definition, incredibly durable image that won’t peel, crack, or fade easily, unlike surface prints.

Our sublimation aluminum sheet products, along with our UV printing aluminum sheet and engraving aluminum sheet, boast excellent performance. We utilize German high-quality raw materials and technology for surface chemical treatment. This process creates a compact honeycomb oxide film on the aluminum surface, ensuring the paints and the aluminum sheet are tightly combined. This leads to the best status with great gloss, adhesion, and corrosion resistance.

Can You Sublimate on Sheet Metal?

Yes, you absolutely can sublimate on sheet metal, provided it has the correct sublimation-receptive coating. You cannot sublimate directly onto raw, untreated metal. The magic lies in that special polymer layer which makes the sublimation aluminum blank ready for your designs.

Finding Quality: Sublimation Aluminum Blank and Suppliers

When embarking on sublimation projects, the quality of your sublimation aluminum blank is paramount. Look for aluminum sublimation metal sheet suppliers who offer consistent coatings, a variety of finishes, and good customer support. High-quality blanks ensure better ink transfer, more vibrant colors, and greater longevity for your finished products. We pride ourselves on being a reliable supplier, offering products made with German high-quality raw materials and advanced surface treatment technology.

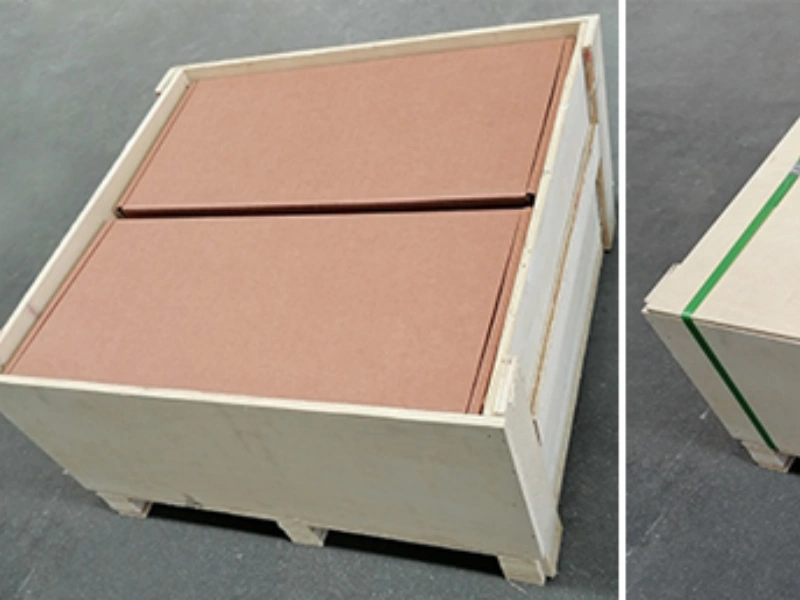

Packaging Considerations

We understand the importance of receiving your materials in perfect condition. Appropriate packaging is utilized to protect the sublimation sheet metal during transit, ensuring it arrives ready for your creative projects.

Why Choose Our Sublimation Aluminum Sheets?

Exceptional Performance: Thanks to German raw materials and advanced surface treatments.

Durability: Compact honeycomb oxide film ensures excellent adhesion and corrosion resistance.

Vibrancy: Achieves great gloss and color depth.

Versatility: Wide range of finishes, thicknesses, and customization options.

Wide Application Range: Suitable for everything from signage to personalized gifts.

Unleash Your Creativity with Sublimation Metal

Sublimation sheet metal, particularly sublimation aluminum sheet, opens up a world of creative possibilities. Its ability to capture stunning, durable, and vibrant images makes it a preferred choice for businesses, artists, and hobbyists alike. Whether you’re interested in a sheet metal for sublimation gloss white, a sophisticated brushed gold, or a sleek mirror silver, the options are extensive.

We are dedicated to providing top-quality sublimation aluminum sheet, UV printing aluminum sheet, and engraving aluminum sheet products. With our commitment to innovation and quality, we aim to be your trusted partner for all your metal printing needs.

Frequently Asked Questions

1. Can you sublimate directly on bare metal?

No – Requires special polymer coating (our sheets come pre-coated).

2. What’s the ideal sublimation temperature?

190°C (374°F) for 60 seconds is optimal for most designs.

3. How durable are sublimated metal prints?

- Indoor use: 10+ years

- Outdoor use: 3-5 years (with UV laminate)

4. What file formats work best?

300dpi resolution in CMYK PDF, TIFF, or PSD.