White anodized aluminum is a highly sought-after material for a variety of applications due to its unique combination of durability, aesthetic appeal, and corrosion resistance. Whether you’re working on an architectural project, consumer product, or industrial component, white anodized aluminum offers a clean, modern look while providing long-lasting performance.

Benefits

- Sleek and Modern Appearance White anodized aluminum has a clean, polished look that enhances the visual appeal of any project. Its smooth and uniform finish gives it a high-end, contemporary appearance, making it an excellent choice for architectural applications, consumer products, and decorative elements.

- Corrosion Resistance Anodizing aluminum significantly enhances its corrosion resistance, making it ideal for both indoor and outdoor applications. White anodized aluminum can withstand harsh environmental conditions. Such as moisture, salt, and chemicals, without degrading, making it perfect for use in coastal areas or industrial settings.

- Durability and Scratch Resistance The anodized surface is much harder than untreated aluminum, providing excellent resistance to wear, scratches, and abrasions. This makes white anodized aluminum a great choice for high-traffic areas or products that require durability. Such as door frames, handles, and signage.

- UV and Weather Protection The anodized finish is UV stable, meaning it won’t fade or discolor when exposed to sunlight. This makes white anodized aluminum an ideal material for outdoor applications where it will be exposed to the elements. Its resistance to weathering ensures that the white color remains vibrant for years to come.

- Lightweight and Strong One of the key advantages of aluminum is its high strength-to-weight ratio. White anodized aluminum retains this characteristic, making it both lightweight and durable. This makes it an excellent choice for applications where weight is a concern. Such as in the automotive or aerospace industries, without sacrificing strength or durability.

- Environmentally Friendly Anodizing is an eco-friendly process that does not involve the use of harmful chemicals. And anodized aluminum is 100% recyclable. This makes white anodized aluminum a sustainable choice for projects that prioritize environmental responsibility.

Common Applications

Thanks to its durability, sleek appearance, and corrosion resistance, white anodized aluminium has applciations in a wide variety of industries and applications:

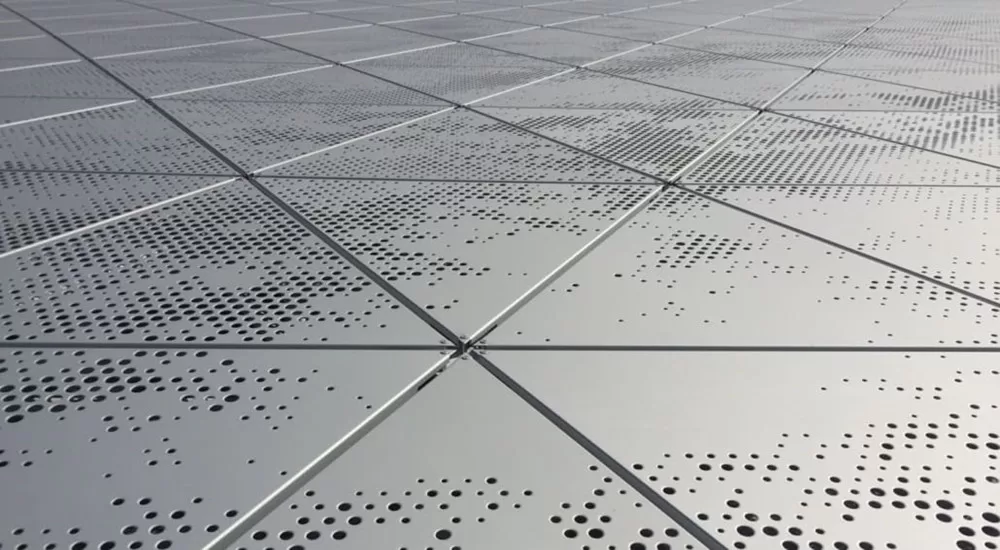

- Architecture and Construction In the architectural field, white anodized aluminium has uses for window frames, door frames, wall panels, and exterior facades. Its modern look and durability make it ideal for both residential and commercial buildings. The material’s resistance to weathering and UV light ensures that it maintains its clean, polished appearance over time.

- Signage and Displays The high contrast and sleek appearance of white anodized aluminium make it a popular choice for signage, plaques, and display panels. It can be easily engraved, providing a durable surface for logos, text, and other designs that will stand out and remain legible for years to come.

- Consumer Products White anodized aluminum has uses in the design of consumer electronics. Such as smartphone casings, laptops, and audio equipment, as well as in appliances and furniture. Its sleek finish adds a touch of elegance to everyday products while offering durability and resistance to wear.

- Automotive and Aerospace In the automotive and aerospace industries, white anodized aluminum has uses for trim, body panels, and interior components. Its lightweight yet strong properties make it ideal for these applications. While the anodized finish ensures long-term protection against the elements.

- Industrial Components White anodized aluminum has uses in various industrial applications, where it provides protection against corrosion, wear, and environmental damage. Common uses include machinery components, enclosures, and hardware, where durability and resistance to harsh conditions are essential.

- Medical and Pharmaceutical Equipment The clean, corrosion-resistant, and durable nature of white anodized aluminum makes it a suitable material for medical devices, pharmaceutical equipment. And other precision instruments where hygiene and resistance to contamination are critical.

Why Choose White Anodized Aluminum?

Choosing white anodized aluminium for your project offers a wide range of benefits, from its attractive appearance to its impressive durability. Here are a few reasons why you should consider this material:

- Customizable Finish: The anodizing process allows for consistent color application that penetrates the metal, resulting in a long-lasting and fade-resistant finish.

- Long-Term Performance: The anodized surface provides superior protection against the elements, ensuring your project remains durable and attractive for many years.

- Low Maintenance: White anodized aluminium is easy to clean and maintain. It doesn’t require frequent repainting or refinishing, saving you time and money on upkeep.

- Sustainability: If you’re working on an eco-conscious project, anodized aluminum is a great choice. Its recyclability and eco-friendly manufacturing process make it a responsible material choice.

What is White Anodized Aluminum?

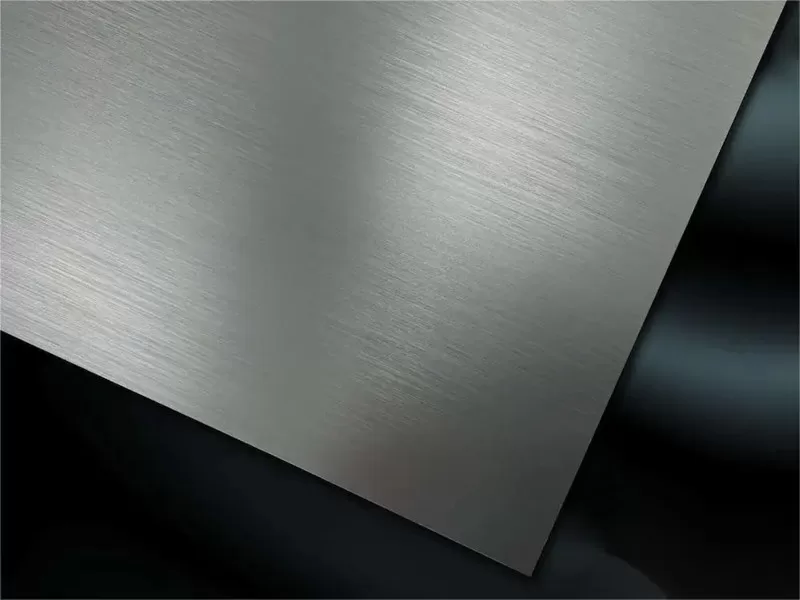

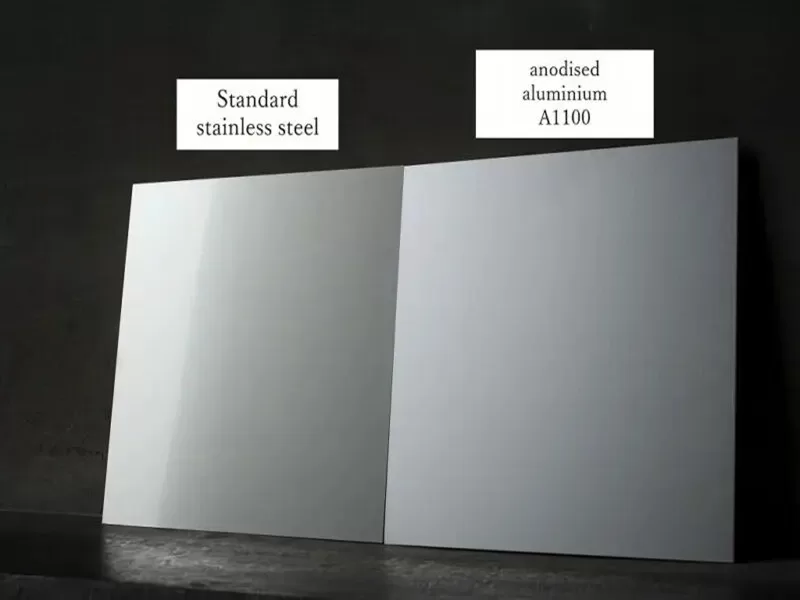

Anodized aluminum undergoes an electrochemical process that thickens the oxide layer on the aluminum surface, improving its durability and resistance to corrosion. This process creates a protective layer that is integral to the aluminum itself.

In the case of white anodized aluminium, a white dye is applied during or after the anodizing process, giving the aluminum a smooth, uniform white finish. This finish becomes part of the metal, making it durable, scratch-resistant, and highly resistant to fading, chipping, or peeling.

Maintenance Tips for White Anodized Aluminum

Although white anodized aluminium is durable and low-maintenance, proper care will help ensure it stays looking its best. Here are a few maintenance tips:

- Regular Cleaning: Clean the surface with a mild detergent and water to remove dirt, grime, and other contaminants. Avoid using harsh chemicals or abrasive materials, as they can damage the anodized surface.

- Avoid Harsh Environments: While anodized aluminum is corrosion-resistant, exposure to extremely acidic or alkaline environments can still cause damage. Use protective measures in highly corrosive environments to maintain the material’s longevity.

- Polishing and Protection: Over time, a protective wax or sealant can help preserve the finish and maintain the aluminum’s sheen. However, always check the manufacturer’s recommendations before applying any products.

Versatile, Durable, and Stylish

White anodized aluminium is a highly versatile and durable material, perfect for a wide range of applications. Its clean, modern appearance, combined with its corrosion resistance and low-maintenance properties, makes it ideal for use in architecture, consumer products, automotive components, and more. Whether you’re looking to enhance the aesthetics of your project or need a strong, lightweight material that will stand the test of time, white aluminum is the right choice.

Consider using white anodized aluminum for your next project to enjoy the benefits of a sleek, long-lasting, and environmentally friendly material.